Tower crane climbing system

A technology of tower body and ladder, applied in the field of tower crane climbing system, can solve problems such as low safety and shaking of counterweight blocks, and achieve the effect of ensuring safe use, reducing the amplitude of shaking and having little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

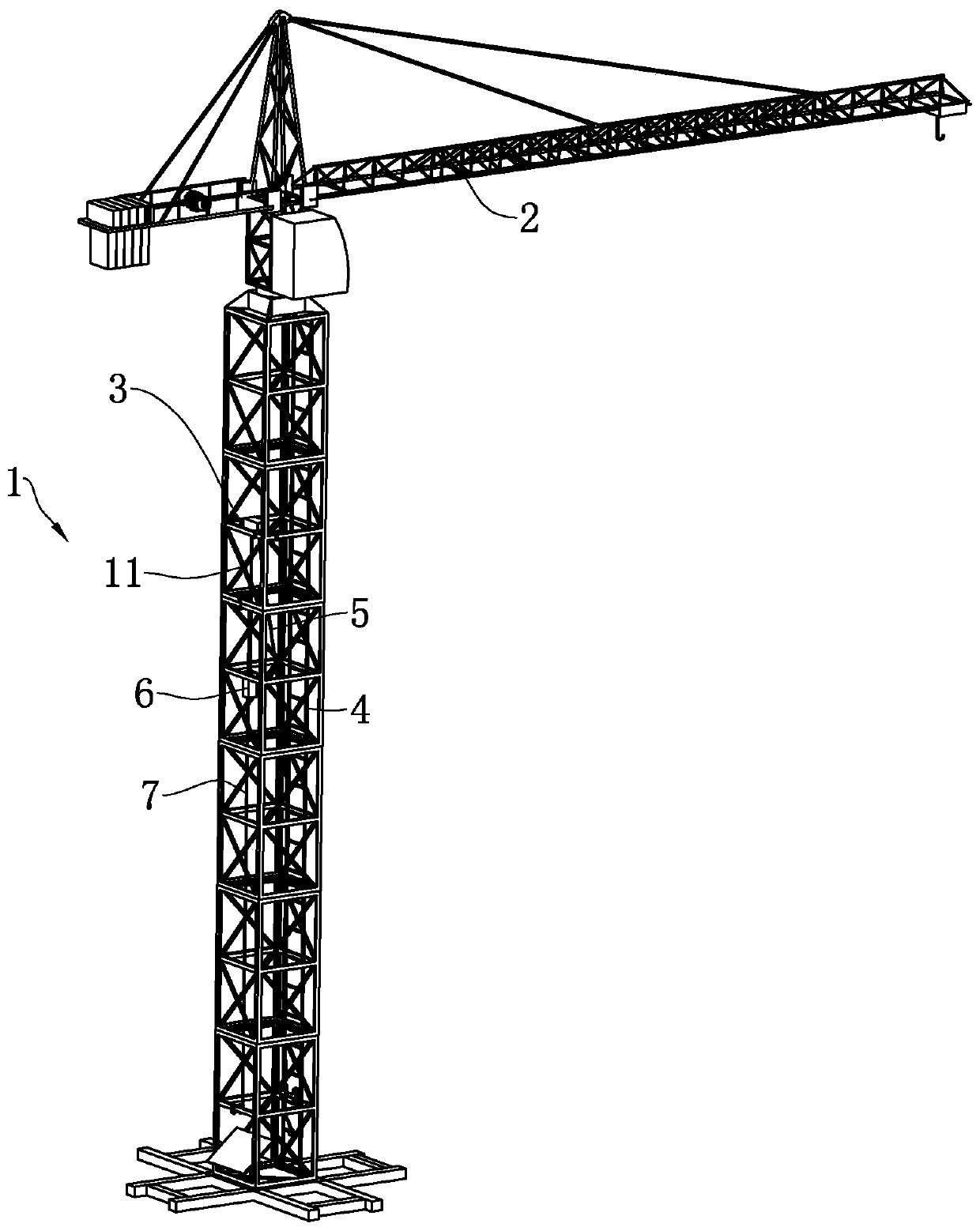

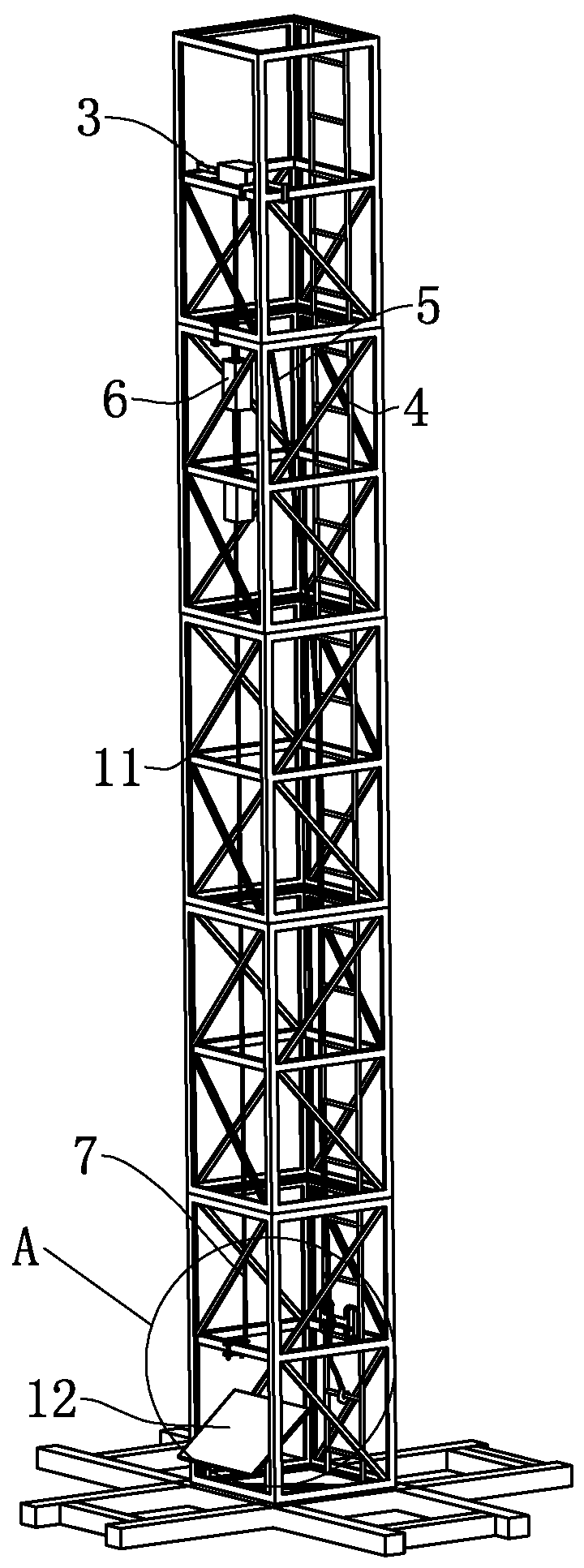

[0040] refer to figure 1 , discloses a tower crane climbing system for the present invention, comprising a tower body 1, the tower body 1 is sequentially connected in the vertical direction using standard joints 11, a base is fixed at the lower end of the tower body 1, and the base is connected to the concrete pouring on the ground, The upper end of the tower body 1 is provided with a jacking mechanism, which is used for the installation and disassembly of the standard section 11. The tower body 1 is provided with a ladder 4 arranged in the vertical direction, and a turning mechanism is arranged above the jacking mechanism. A boom 2 and a balance arm are provided.

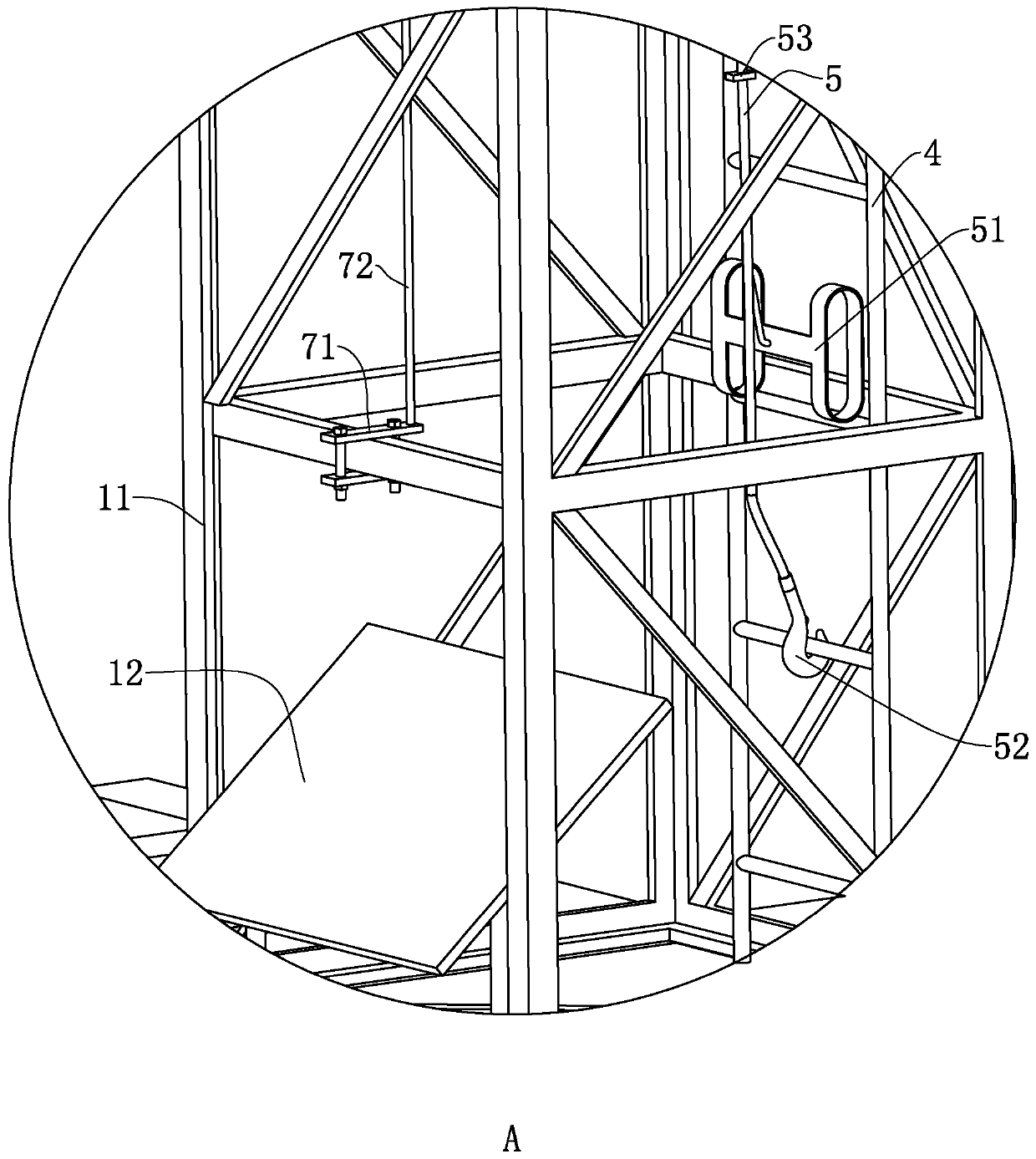

[0041] refer to figure 2 and Figure 4 , the top of the tower body 1 is detachably connected with a fixed shaft 3, the fixed shaft 3 is located below the jacking mechanism, the fixed shaft 3 includes an inner tube 32, the inner tube 32 is a round tube, and the two ends of the inner tube 32 are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com