PCB perforating device for electronic processing

A PCB board and electronic technology, which is applied in the field of PCB board hole opening device for electronic processing, can solve the problem of low flexibility of drilling operation, and achieve the effect of flexible and efficient drilling operation and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

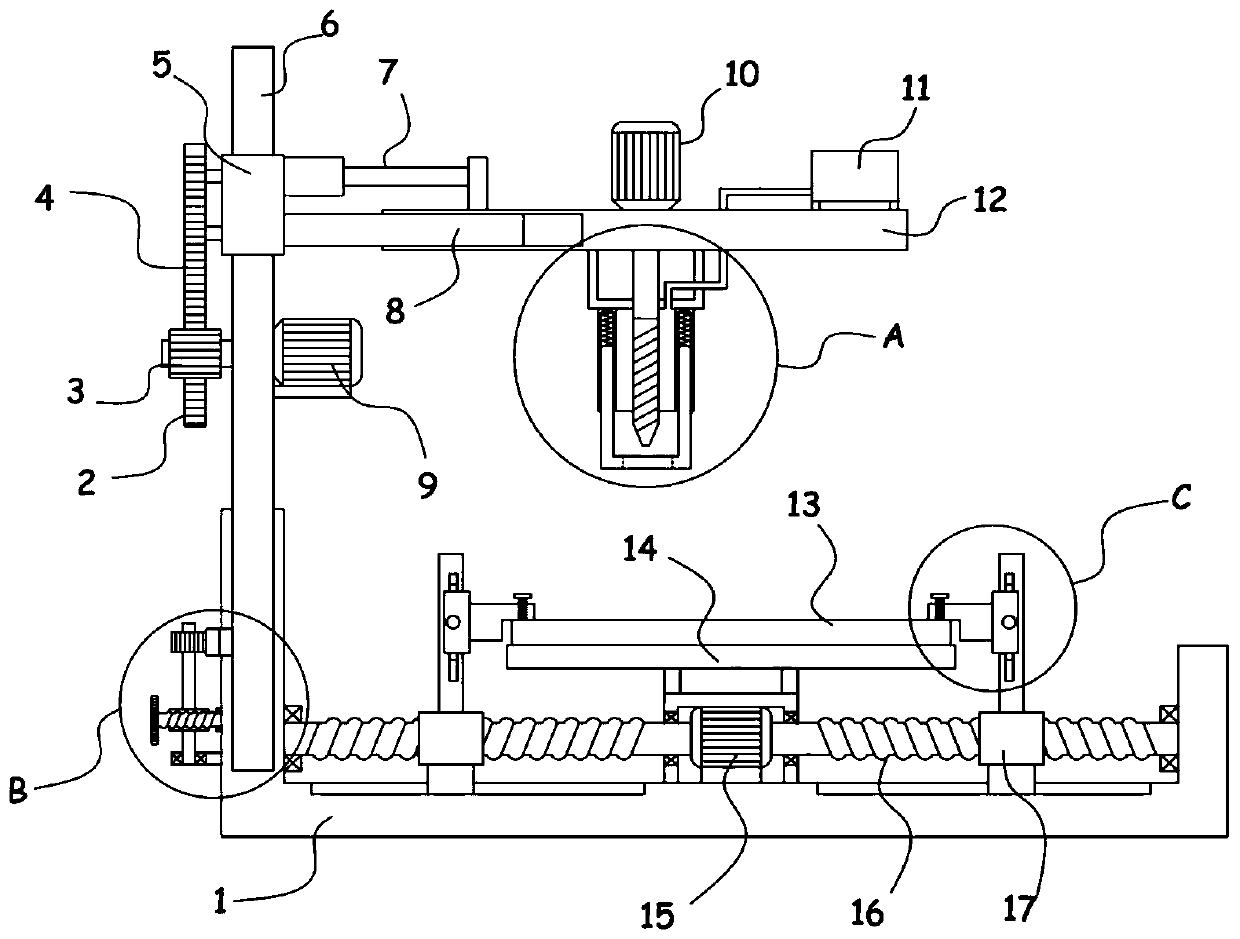

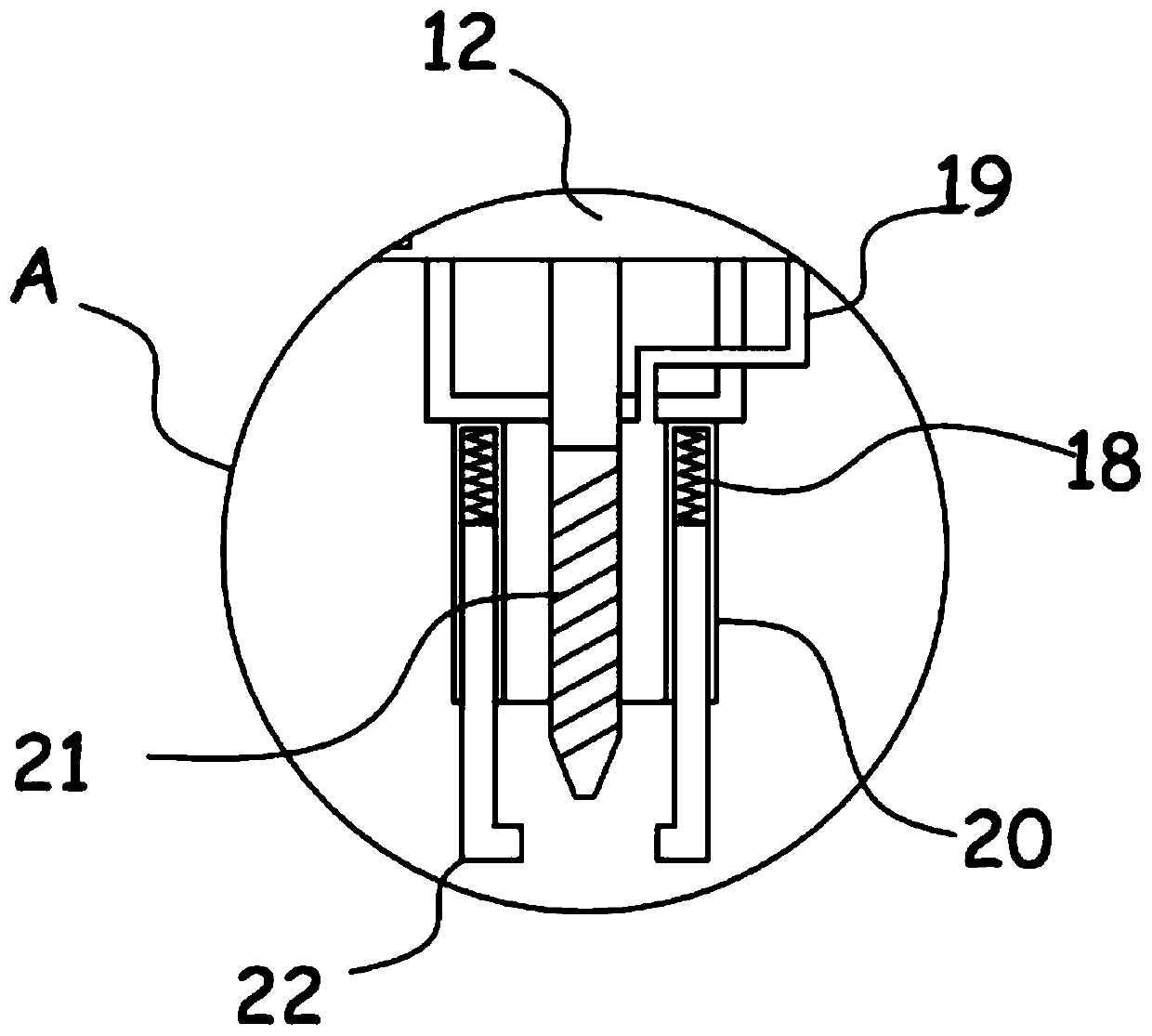

[0026] see Figure 1-5 , a PCB board opening device for electronic processing, comprising a fixed frame 1, a support seat 14 for supporting a PCB board 13 is fixed on the fixed frame 1, a biaxial motor 15 is fixed on the fixed frame 1, and a biaxial motor 15 The upper drive is connected with a clamping mechanism for clamping and fixing the PCB board 13. A cover plate 12 is horizontally installed on the fixed frame 1 through a lifting mechanism, and a drill bit 21 driven by a motor II10 is fixed on the bottom of the cover plate 12. The drill bit 21 is covered with a dust collection mechanism, and the fixed frame 1 is provided with a steering mechanism for driving the sleeve plate 12 to rotate.

[0027] The support seat 14 provided in this device is used to support and place the PCB board 13 to be drilled, and the PCB board 13 is clamped and fixed by the clamping mechanism, so as to ensure that the PCB board 13 is stable and does not shake when the hole is opened, and the motor ...

Embodiment 2

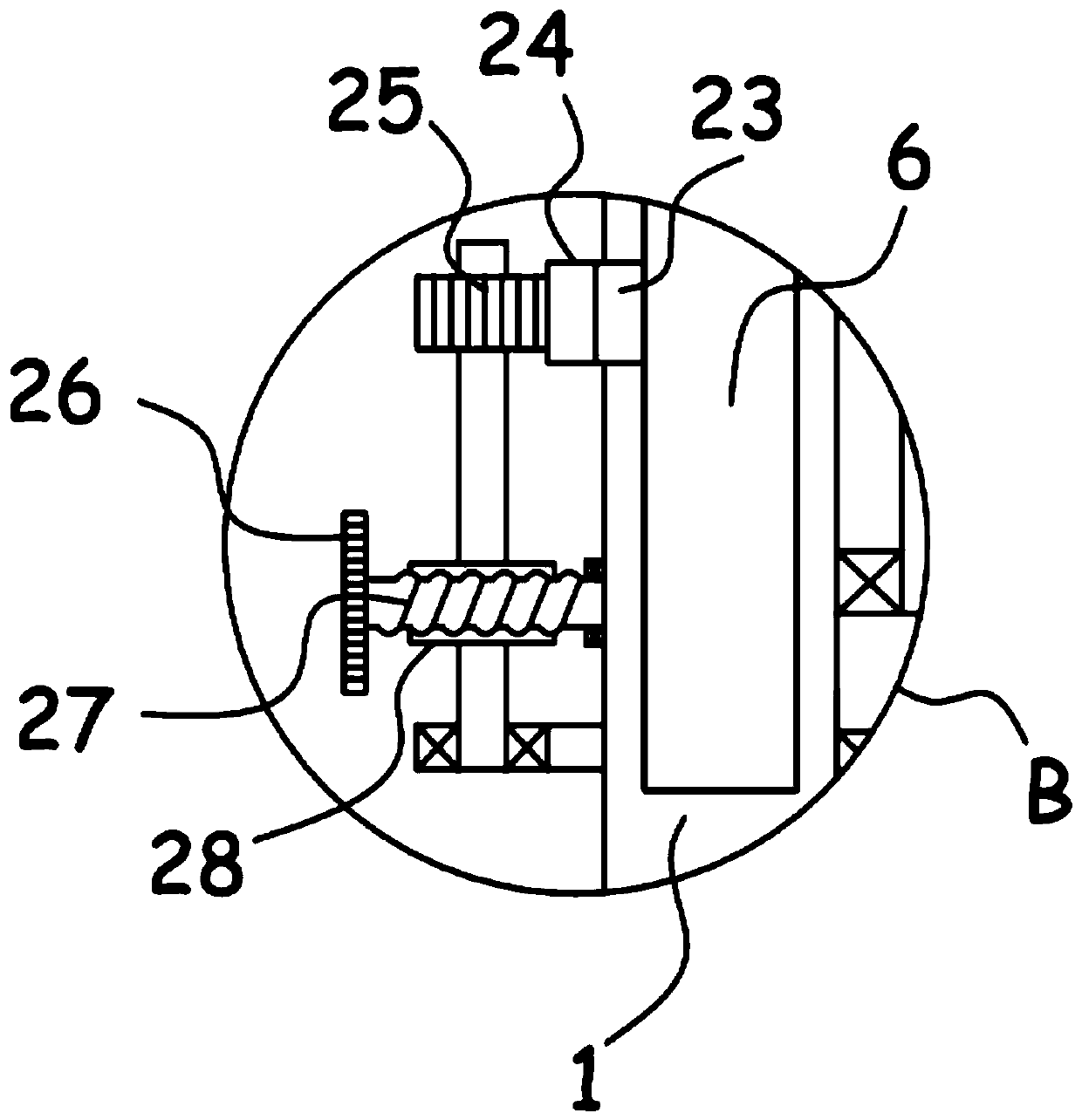

[0032] On the basis of Embodiment 1, in addition, the lifting mechanism includes a vertical rod 6 vertically installed on the fixed frame 1, and the vertical rod 6 is sleeved with a lifting sleeve 5 connected to the cover plate 12 through a translation mechanism. A motor 19 is fixed on the bar 6, and a gear 13 is driven on the motor 19, and the gear 13 is meshed with a tooth bar 4 that is vertically fixed on the lifting cover 5.

[0033] The motor I9 can drive the gear I3 to rotate, and the gear I3 drives the straight rack 2 to lift vertically, and the straight rack 2 drives the lifting sleeve 5 to slide vertically relative to the vertical rod 6, so that the sleeve plate 12 drives the drill bit 21 to adjust the vertical height As a result, sufficient drilling operation of the drill bit 21 on the PCB board 13 is realized.

[0034] Wherein, the translation mechanism includes an electric push rod 7 horizontally fixed on the side wall of the lifting sleeve 5, the telescopic end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com