A brushless power feedback permanent magnet speed control device combining axial and radial magnetic flux

A technology of radial magnetic flux and permanent magnet speed regulation, applied in electromechanical devices, magnetic circuit shape/style/structure, permanent magnet clutch/brake, etc., can solve the problem of reducing the torque density and speed regulation of permanent magnet governors The efficiency of the device is low, the strength of the air gap magnetic field is weakened, etc., so as to improve the space utilization rate, solve the heat dissipation problem, and improve the operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

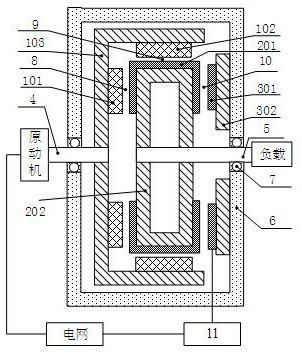

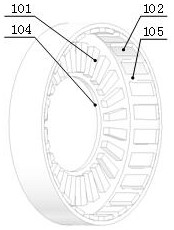

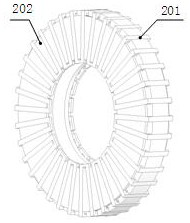

[0027] Such as figure 1 As shown, a brushless power feedback type permanent magnet speed regulating device with axial and radial flux combined, the device mainly includes a permanent magnet speed governor with axial and radial flux combined and a slip power feedback control unit. The permanent magnet governor includes a concentrically installed permanent magnet rotor, a conductor rotor and a three-phase winding stator; the permanent magnet rotor is fixed on the input shaft 4 and connected to the prime mover, and the conductor rotor is fixed on the output shaft 5 and connected to the load , the three-phase winding stator is fixed together with the casing 6, and is connected with the output shaft 5 through the bearing 7; The inner side of the magnetic rotor back iron core 103 is formed; the conductor rotor is composed of a bent three-phase con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com