Curved glass screen size measuring method

A measurement method and technology of curved glass, applied in mechanical counter/curvature measurement, measuring device, mechanical measuring device, etc., can solve problems such as inaccurate measurement results and inability to realize all-round measurement, and achieve the effect of eliminating false defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

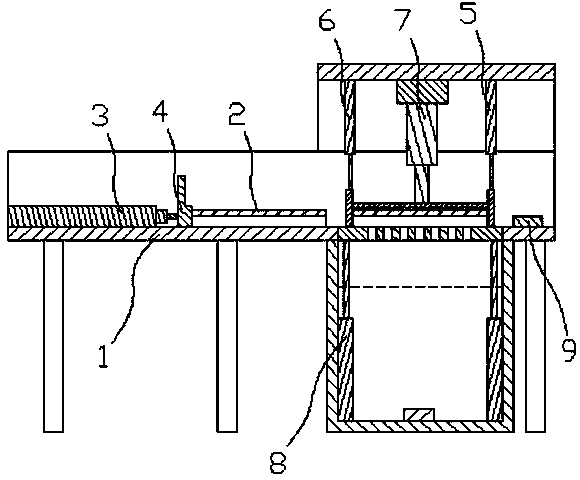

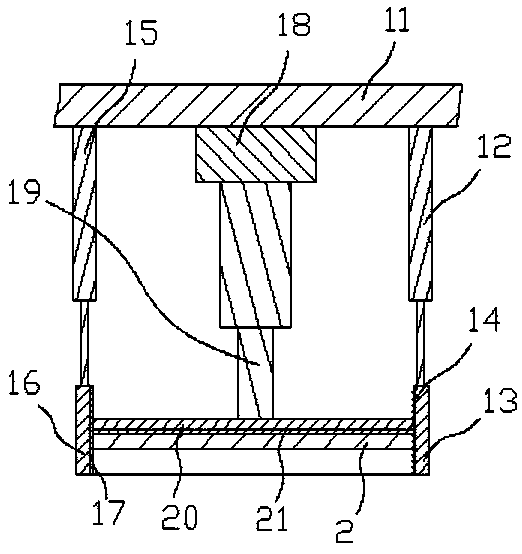

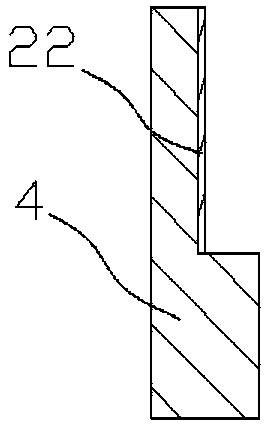

[0030] like Figure 1-4 As shown, the specific structure of the present invention is: a device used in the method of measuring the size of a curved glass screen, including a delivery trough 1, a push block 4 cooperating with the product 2 is arranged in the delivery trough 1, and the push block 4 4 is connected with a push cylinder 3, and a detection frame 11 is arranged above the conveying trough 1, and the side of the detection frame 11 away from the push block 4 is provided with an intercepting device 5, and the side close to the push block 4 is provided with a length Measuring device 6, the middle part is provided with outer arc measuring device 7, and described length measuring device 6 comprises the length measuring cylinder 15 that is arranged on the detection frame 11 below, and described length measuring cylinder 15 is connected with length measuring lifting block 16, and described The length measurement lifting block 16 is provided with a length measurement touch sen...

Embodiment 2

[0041] like Figure 1-5 As shown, the specific structure of the present invention is: a device used in the method of measuring the size of a curved glass screen, including a delivery trough 1, a push block 4 cooperating with the product 2 is arranged in the delivery trough 1, and the push block 4 4 is connected with a push cylinder 3, and a detection frame 11 is arranged above the conveying trough 1, and the side of the detection frame 11 away from the push block 4 is provided with an intercepting device 5, and the side close to the push block 4 is provided with a length Measuring device 6, the middle part is provided with outer arc measuring device 7, and described length measuring device 6 comprises the length measuring cylinder 15 that is arranged on the detection frame 11 below, and described length measuring cylinder 15 is connected with length measuring lifting block 16, and described The length measurement lifting block 16 is provided with a length measurement touch sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com