Gear shifting mechanism for transmission

A shifting mechanism and transmission technology, applied in the direction of instruments, controlled components, mechanical equipment, etc., can solve the problems of low precision, low rotation speed, and difficult integration, so as to improve shifting accuracy, reduce shifting time, and improve The effect of shift comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

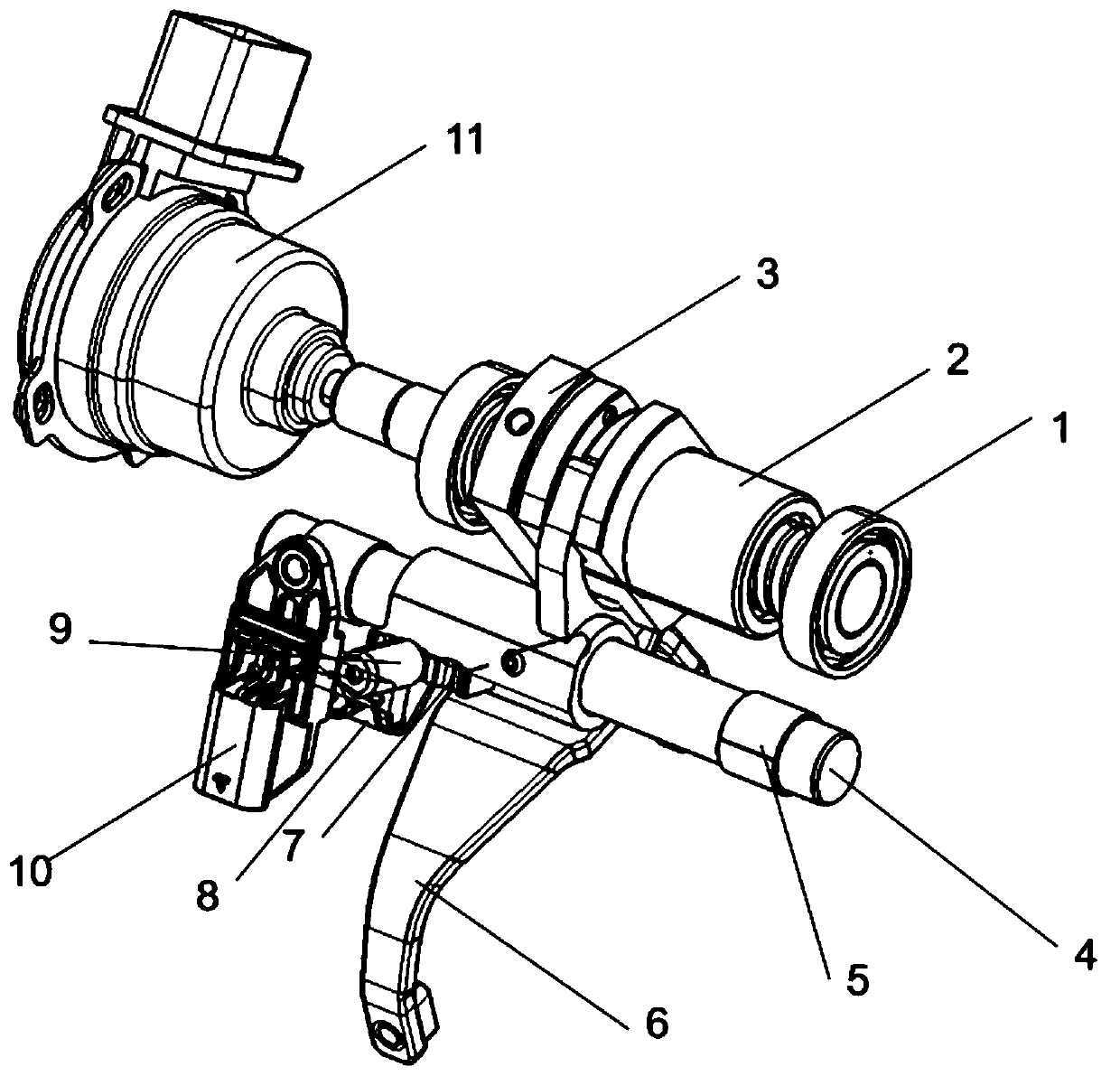

[0022] Such as figure 1 , 2 As shown, this embodiment provides a shift mechanism for a transmission, including a bearing 1, a rolling screw 2, a nut 3, a guide rod 4, a sliding sleeve 5, a shift fork 6, a limit block 7, a magnet 8, and an elastic cylinder Pin 9, sensor 10, and motor 11. In this scheme, the motor directly drives the rolling screw, and the rolling screw is fixedly connected to the guide rod through a nut, which drives the guide rod to move axially, and then drives the shift fork to move axially to realize gear shifting. When shifting, the transmission TCU controls the speed of the shifting motor according to the shifting strategy to ensure better shifting comfort when the shifting time is relatively small. In addition, there is a limited self-locking device on the shift fork. After shifting gears, the elastic cylindrical pin is located in the groove of the limit block to ensure that the synchronizer will not be out of gear when the corresponding gear is in posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com