A bottom valve of oil pressure shock absorber

A technology of oil pressure shock absorber and bottom valve, which is applied in the field of oil pressure vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

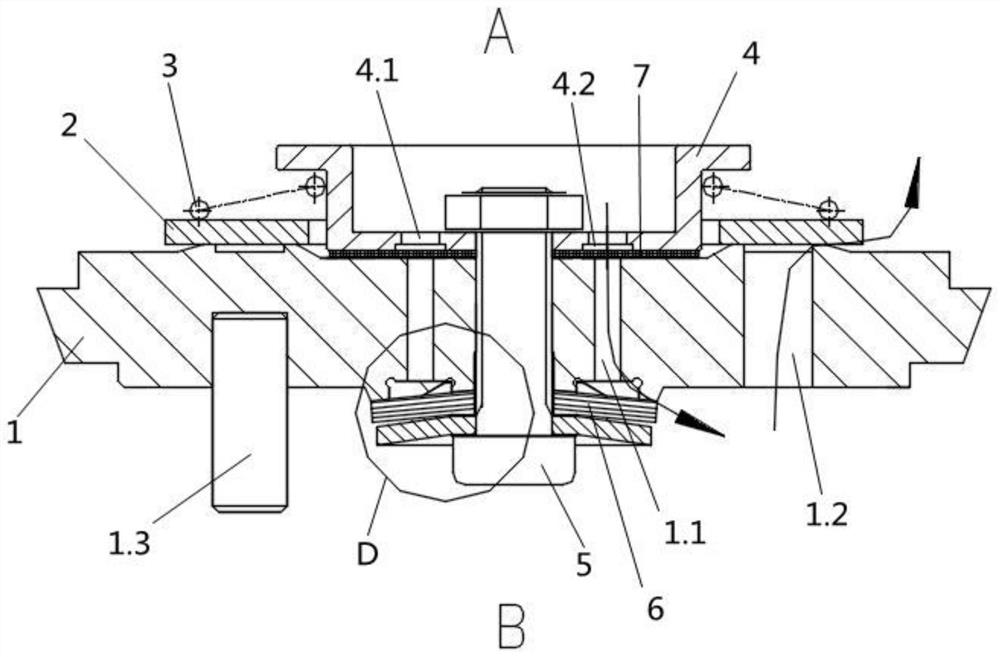

[0037] see Figure 1 to Figure 3 , a bottom valve of an oil pressure shock absorber. This embodiment is applied to the one-way flow and filtration of the oil of the oil pressure shock absorber at the bottom valve.

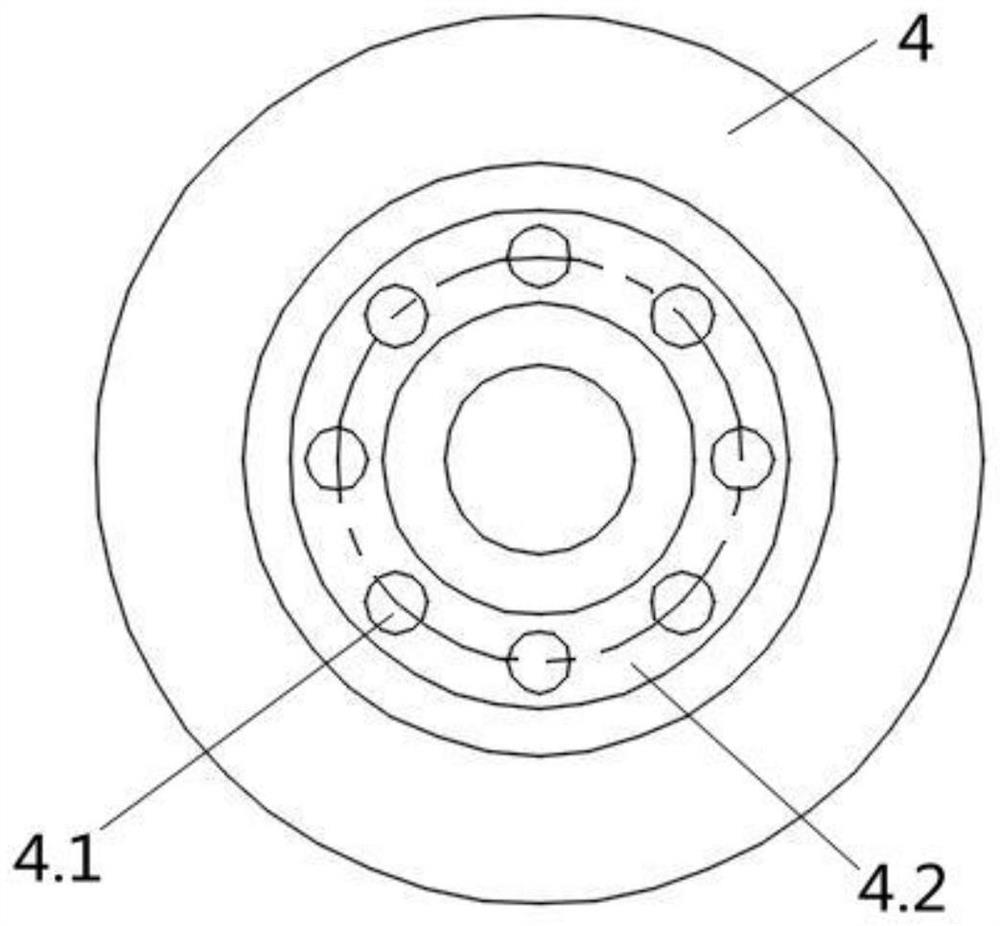

[0038] A bottom valve for an oil pressure shock absorber, comprising a bottom valve body 1, a valve plate 2, a spring 3, a valve plate cover 4, a bottom valve core shaft 5 and a bottom valve system 6;

[0039] The bottom valve body 1 includes a first flow hole 1.1 through the bottom valve body 1, a second flow hole 1.2 and a bottom valve core shaft installation hole for installing the bottom valve core shaft 5;

[0040] A filter device 7 is provided between the end face of the first end of the bottom valve body 1 and the end face of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com