Steel cord plastic clapboard rigidity detection device

A technology of plastic partitions and detection devices, which is applied in the direction of measuring devices, elastic testing, machine/structural parts testing, etc., can solve the problems of low accuracy, no discrimination selection method, large randomness, etc., and improve work Efficiency, reducing human subjective judgment error, and improving the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

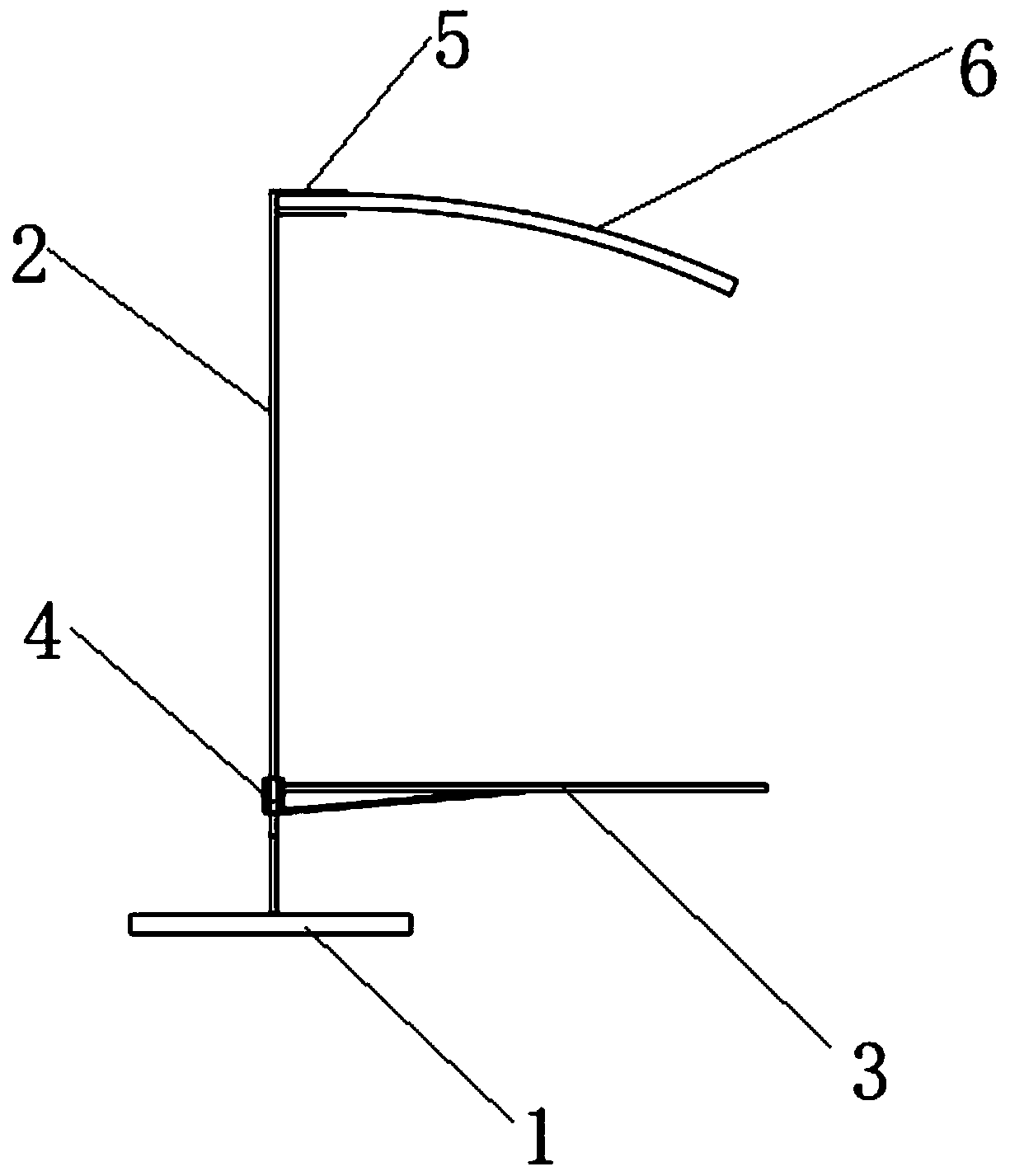

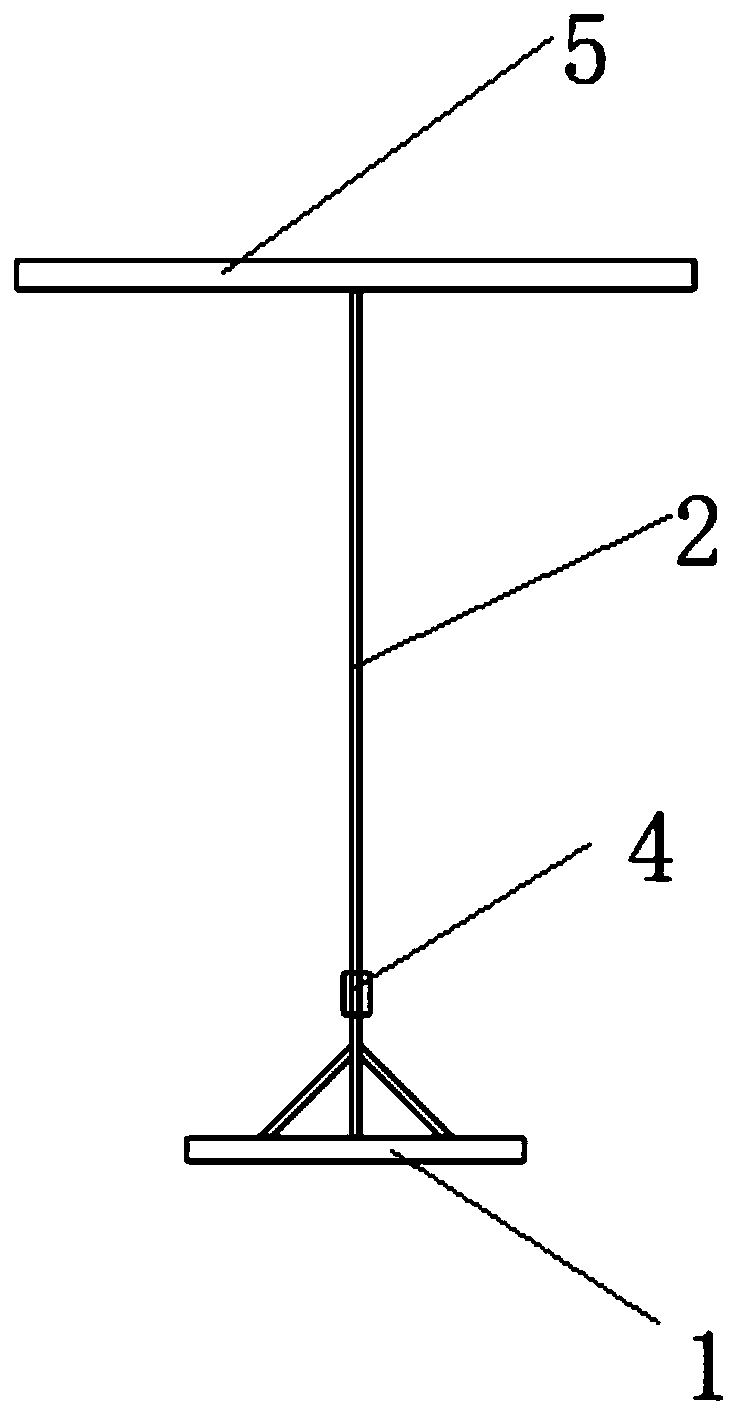

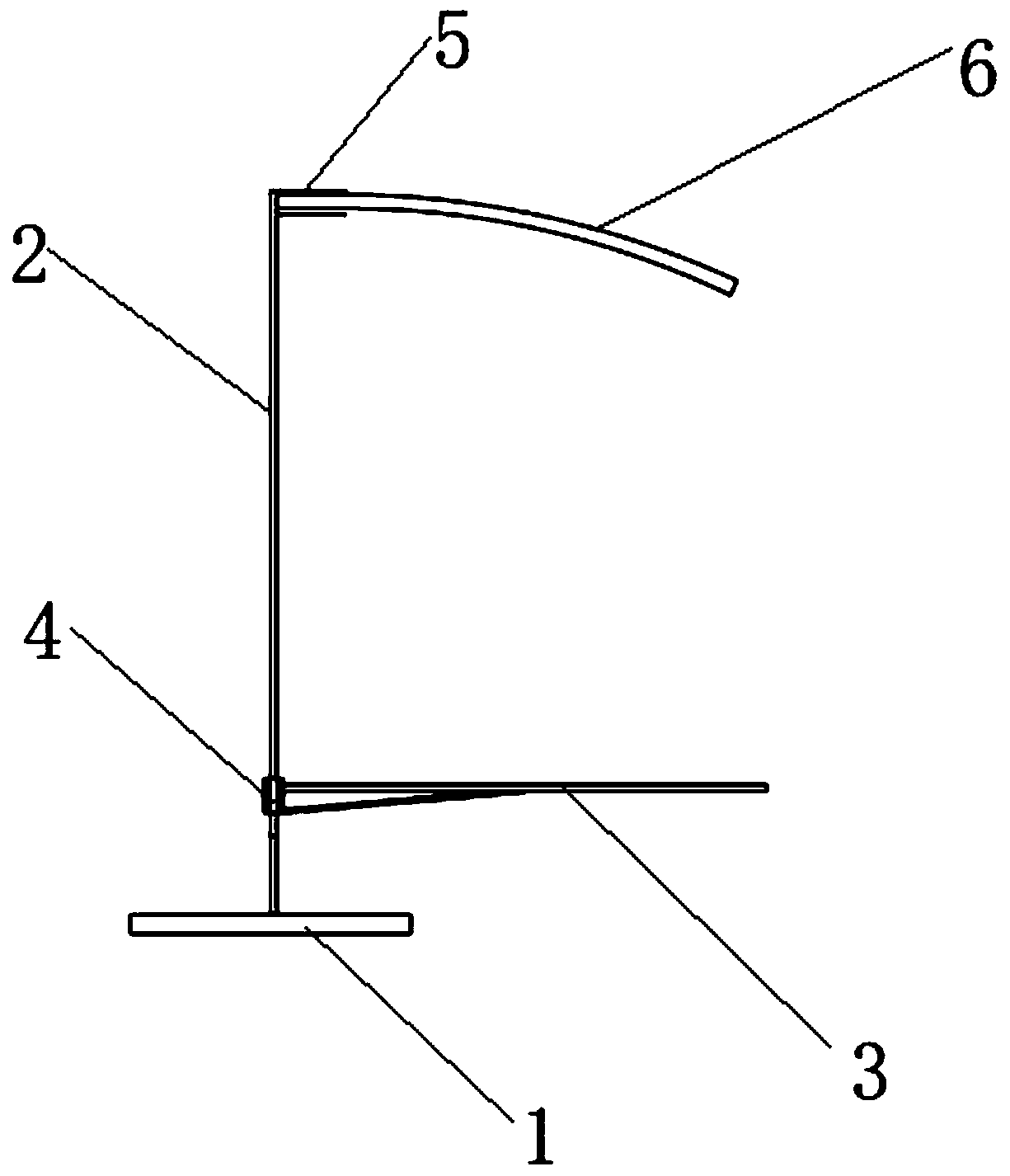

[0017] see Figure 1-Figure 2 As shown, the present invention discloses a steel cord plastic partition rigidity detection device, comprising a base 1, on which a column 2 is arranged; Support components, so as to ensure more stable support of the column.

[0018] The column 2 is provided with a uniform scale, and the end of the column 2 is provided with a partition installation part 5; the partition installation part 5 is a groove structure, and its concave part is used for one end of the plastic partition 6 to be clamped inside the groove , the other end of the plastic partition 8 is a free end; the length of the recess along the axial extension direction of the plastic partition 6 is 8% of the total length of the plastic partition 6 .

[0019] The column 2 is also provided with a scale rod 3 that moves longitudinally on the column 2; the scale rod 3 is arranged horizontally along the axial extension direction of the plastic partition 6; The sliding block 4 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com