Trestle-type full-section inverted arch secondary-lining trolley equipment and construction method thereof

A lining trolley and full-section technology, which is applied to trestle-type full-section inverted arch secondary lining trolley equipment and its construction field, can solve the problems of extended construction period of guide columns, low construction efficiency, and high various costs, and achieve reduction The effect of inputting personnel and auxiliary equipment, ensuring construction quality and saving construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

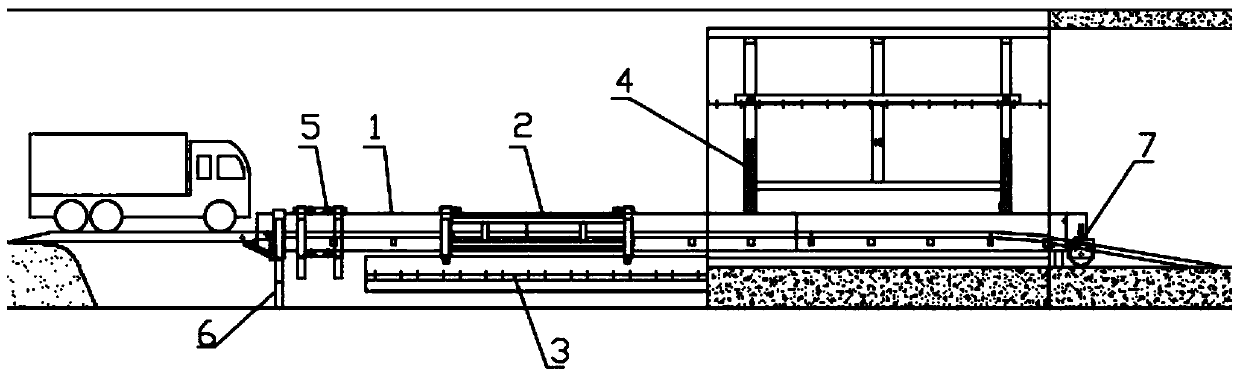

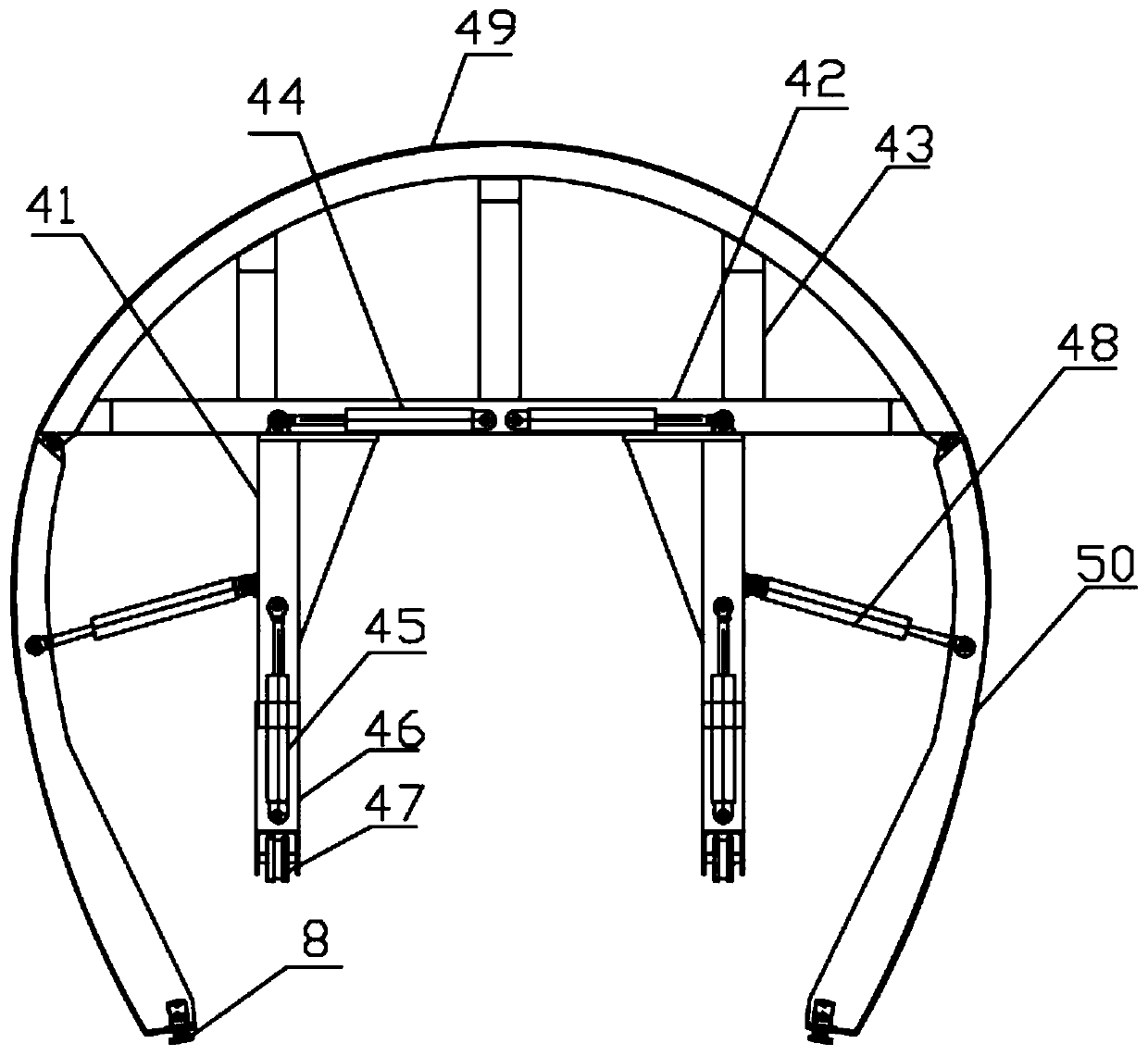

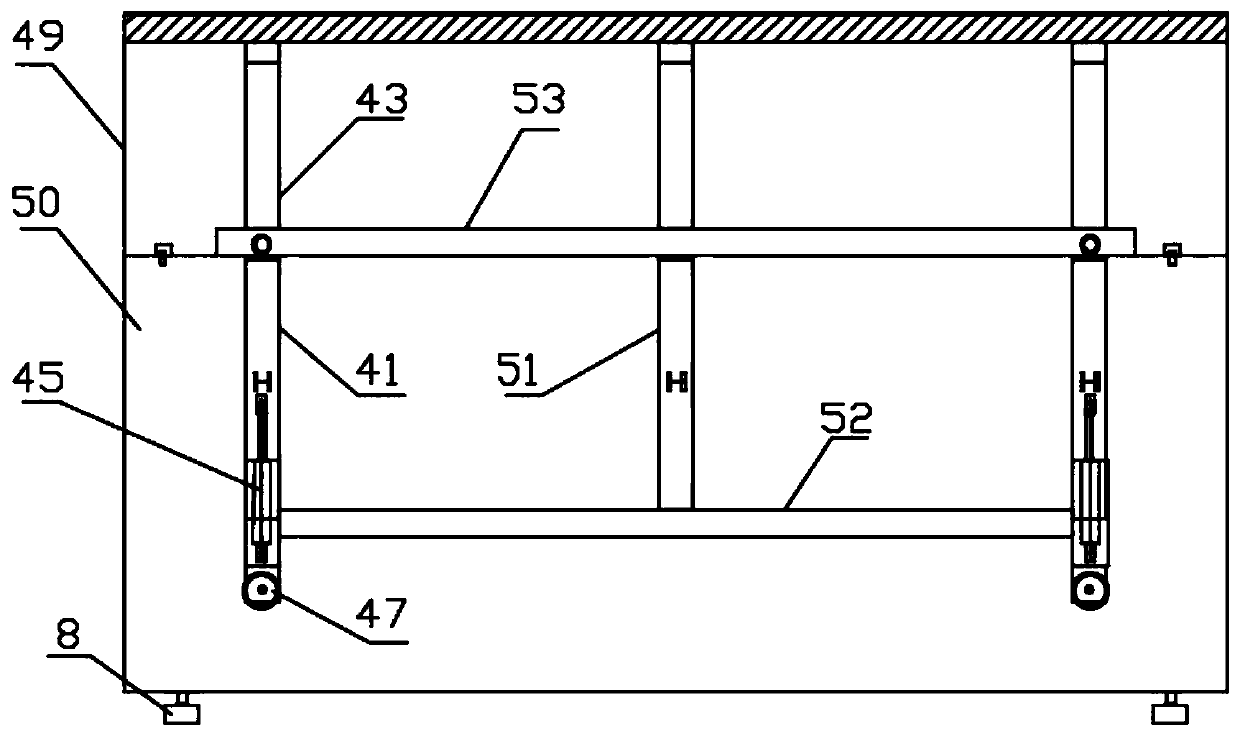

[0061] Such as Figure 13-16 As shown, a construction method of trestle-type full-section inverted arch two-lined trolley equipment includes the following construction steps:

[0062] In the first step, the inverted arch formwork trolley 2 on the self-propelled trestle 1 passes through the inverted arch formwork 3 to complete the pouring and molding of the tunnel bottom, and then drives the inverted arch formwork 3 to move to the next section for construction; the second lining trolley 4 is On the self-propelled trestle 1, move to the inverted arch formwork trolley 2 to carry out the pouring construction of the tunnel top surface through the second lining formwork in a completed work area; The car frame is suspended above the self-propelled trestle 1;

[0063] In the second step, the second lining trolley 4 completes the pouring and molding of the top surface of the tunnel, and the inverted arch formwork trolley 2 completes the pouring and molding of the bottom of the next se...

Embodiment 2

[0068] Such as Figure 13 , 14 , 15, 17, and 16, a construction method for trestle-type full-section inverted arch two-lined trolley equipment includes the following construction steps:

[0069] In the first step, the inverted arch formwork trolley 2 on the self-propelled trestle 1 passes through the inverted arch formwork 3 to complete the pouring and molding of the tunnel bottom, and then drives the inverted arch formwork 3 to move to the next section for construction; the second lining trolley 4 is On the self-propelled trestle 1, move to the inverted arch formwork trolley 2 to carry out the pouring construction of the tunnel top surface through the second lining formwork in a completed work area; The car frame is suspended above the self-propelled trestle 1;

[0070] In the second step, the second lining trolley 4 completes the pouring and molding of the top surface of the tunnel, and the inverted arch formwork trolley 2 completes the pouring and molding of the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com