Fully mechanized coal mining face retracement end mining method

A technology of fully mechanized working face and working face, which is applied in ground mining, mining equipment, earthwork drilling and other directions, can solve the complex change law of surrounding rock force, the difficulty of determining and reducing the cracks and mechanical properties of the roof rock stratum of the retract roadway. Production efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0134] The final mining method of retraction in fully mechanized mining face, taking Ningtiaota Coal Mine 1 -2 Take the N1114 working face as an example.

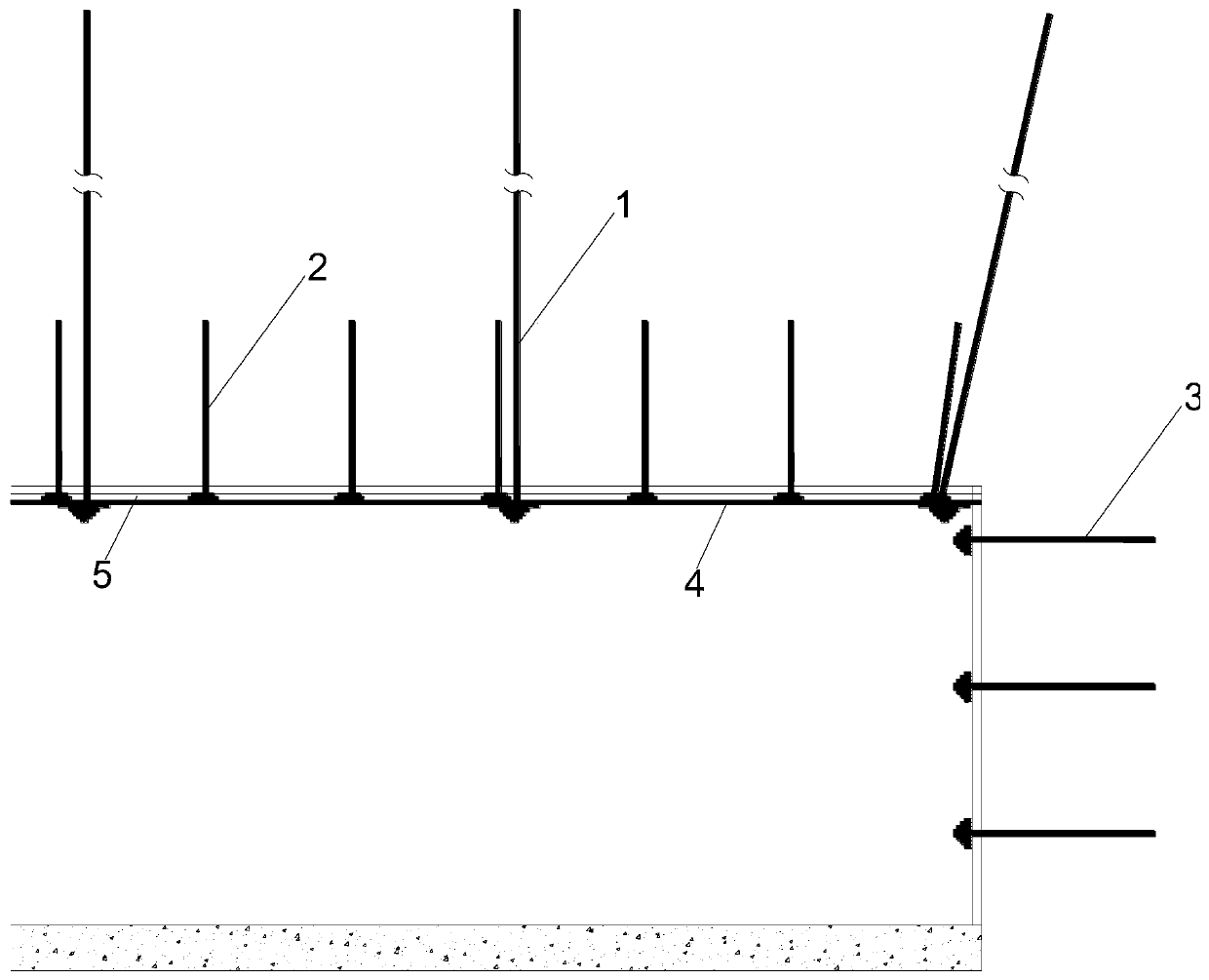

[0135] Step 1. When the working face is withdrawn to a distance of 200m from the withdrawal channel, the hydraulic support of the working face is overhauled to ensure that the hydraulic support of the working face meets the initial support force requirements for mine pressure control in the final mining stage;

[0136] Step 2: When the working face is withdrawn to a distance of 150m to 100m from the withdrawal channel, install stacking brackets in the withdrawal channel;

[0137] Step 3: When the working face is recovered to a distance of 50m from the withdrawal channel, the hydraulic support in the working face and the stacked support in the withdrawal channel are repaired and replenished, so that the hydraulic support of the working face meets the design initial support force requirements;

[0138] Step 4. When the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com