Cutter deceleration method and device

A technology of cutter and deceleration movement, which is applied in the direction of printing device, printing, metal processing, etc. It can solve the problems of bumping into the printer, damage of the cutter, and bad printer body, and achieve the effect of avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

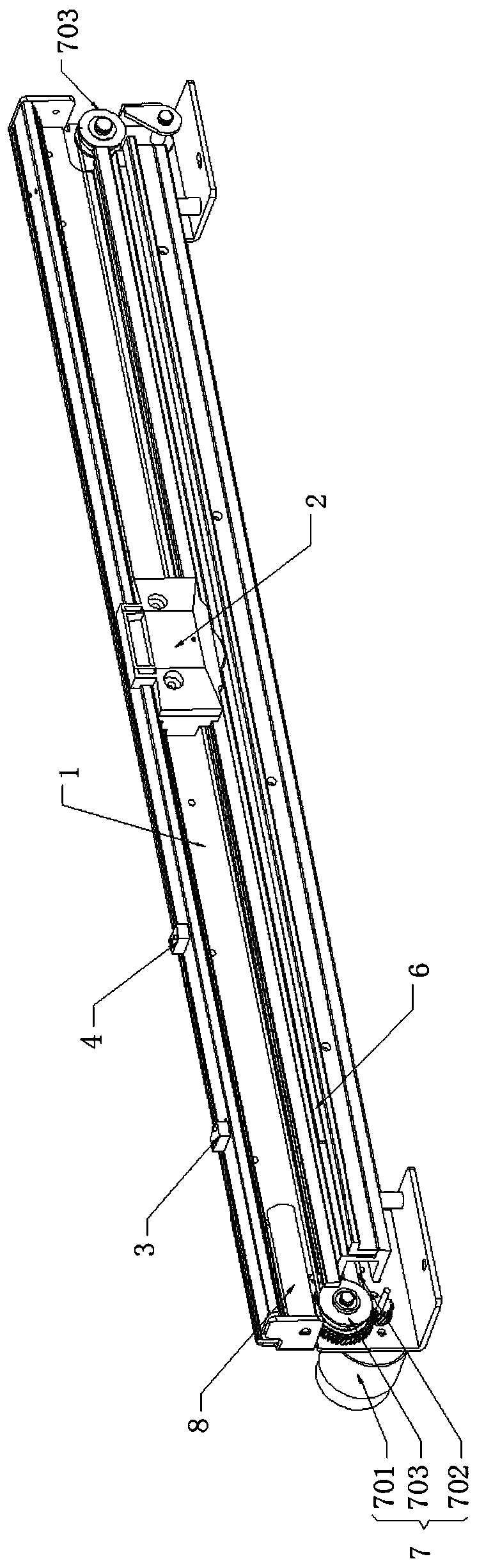

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0036] Such as Figure 1-Figure 2 As shown, the present embodiment provides a cutter deceleration method, including:

[0037] Step 1: The cutter accelerates from the starting position to the first speed V 0 , and then at the first velocity V 0 Straight line motion at a constant speed towards the end position;

[0038] Step 2: After the cutter approaches the end position, it decelerates to a speed of 0, then accelerates in the opposite direction to a designated position, and the speed when it reaches the designated position is the second speed V 2 , and then decelerate from the specified position until the speed is 0.

[0039] As a further solution of this embodiment, V 2 0 .

[0040] As a further solution of this embodiment, step 3 is also included: the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com