Rotary sleeve tool of steel wire rope tightening of automobile glass lifter and rapid steel wire rope assembling method

A technology for automotive glass and lifters, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of abnormal product noise, large force on wire ropes, easy deformation, etc., and achieve the effect of convenient operation, simple assembly, and improved deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation, features and effects according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

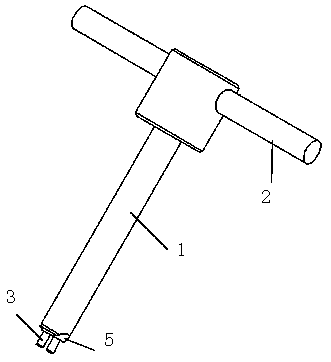

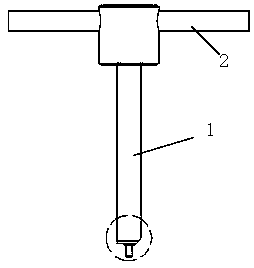

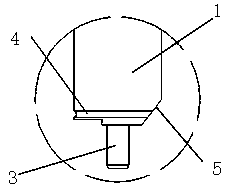

[0020] See 1-7, a steel wire rope swivel tooling for an automobile glass regulator, including a cylindrical main body 1 and a rotating handle 2, the cylindrical main body 1 and the rotating handle 2 are vertically fixedly connected, the front end of the cylindrical main body 1 has a slope 5, and The front end of the cylindrical main body 1 has a double-claw positioning column 3, which is perpendicular to the rotary handle 2. The front end of the cylindrical main body 1 is processed with a spiral groove 4, which is used to guide the wire rope, and the tail of the spiral groove 4 Connect with ramp 5.

[0021] A method of quickly assembling the steel wire rope into the pulley track groove with a steel wire rope swivel tooling for an automobile glass regulator, using the front double c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com