Tool changer reset method and device

A reset method and tool magazine technology, applied in feeding devices, automatic control devices, metal processing machinery parts, etc., can solve problems such as low efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

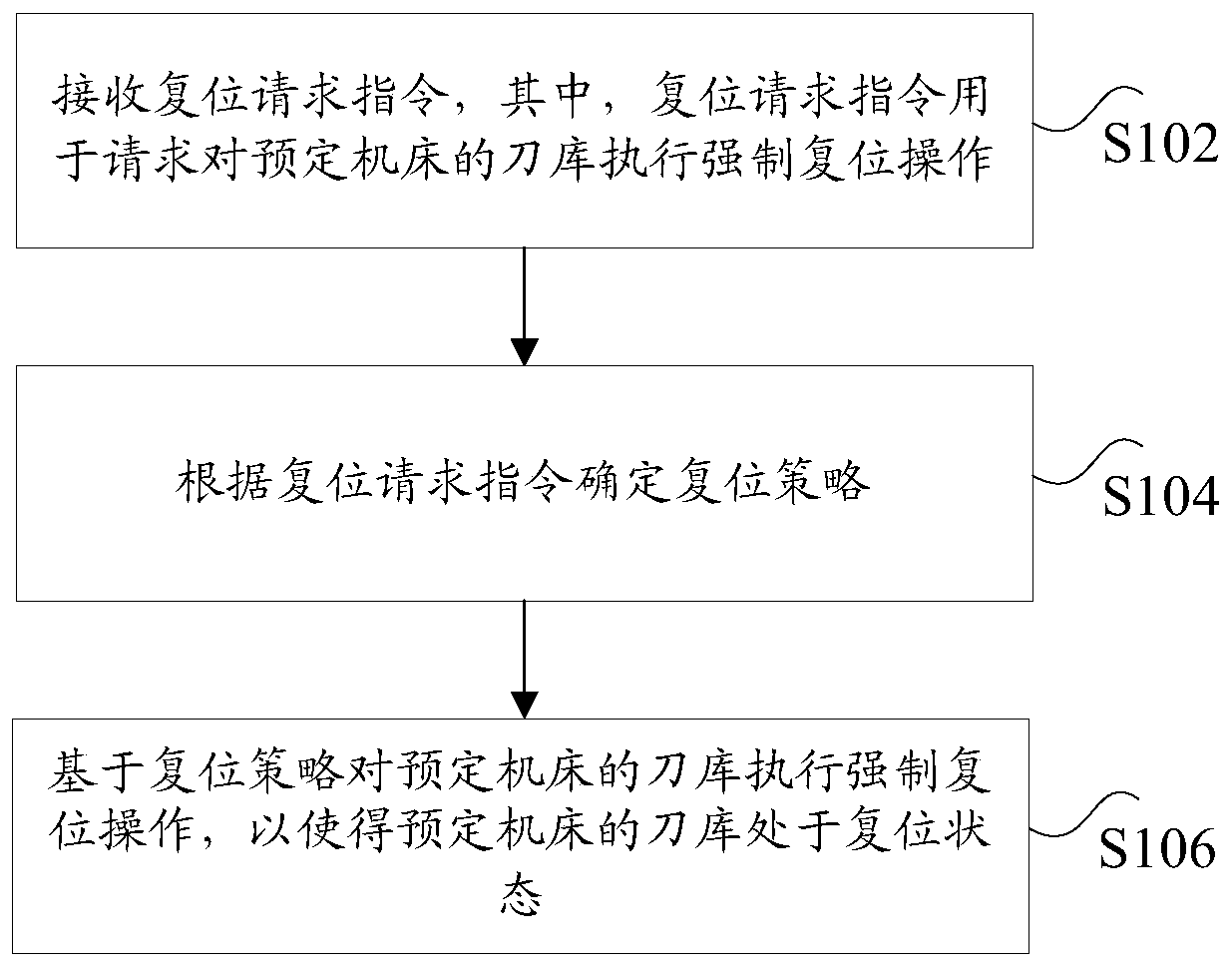

[0026] According to an embodiment of the present invention, a method embodiment of a method for resetting a tool magazine is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, Also, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0027] figure 1 It is a flow chart of the reset method of the tool magazine according to the embodiment of the present invention, as figure 1 As shown, the reset method of the tool magazine includes the following steps:

[0028] Step S102, receiving a reset request instruction, wherein the reset request instruction is used to request a forced reset operation on the tool magazine of the predetermined machine tool.

[0029] Step S104, determining a reset strategy according to the reset request in...

Embodiment 2

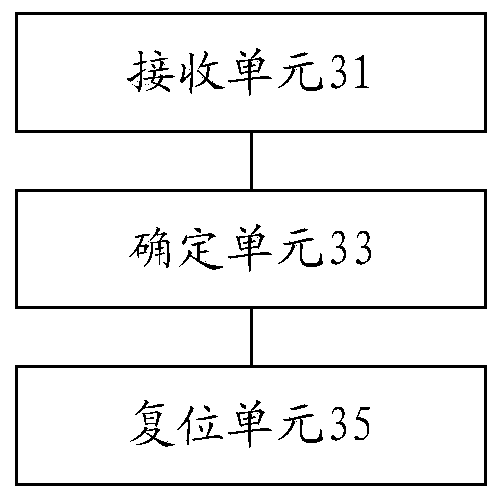

[0043] According to another aspect of the embodiments of the present invention, an embodiment of a device for performing a tool magazine reset method is also provided, image 3 It is a schematic diagram of the reset device of the tool magazine according to the embodiment of the present invention, such as image 3 As shown, the resetting device of the tool magazine includes: a receiving unit 31 , a determining unit 33 and a resetting unit 35 . The reset device of the tool magazine will be described in detail below.

[0044] The receiving unit 31 is configured to receive a reset request instruction, wherein the reset request instruction is used to request a forced reset operation on a tool magazine of a predetermined machine tool.

[0045] The determining unit 33 is configured to determine a reset strategy according to the reset request instruction.

[0046] The reset unit 35 is configured to perform a forced reset operation on the tool magazine of the predetermined machine to...

Embodiment 3

[0054] According to another aspect of the embodiments of the present invention, a storage medium is also provided, and the storage medium includes a stored program, wherein the program executes any one of the tool magazine reset methods described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com