Method and device for assembling multiple shaft parts with angle requirements in deep hole

A technology of shaft parts and deep holes, which is applied in the field of mechanical assembly, can solve problems such as a large amount of time spent on assembly, secondary pollution of the shell, and narrow space, and achieve stable and reliable operation, improve production efficiency, and meet production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

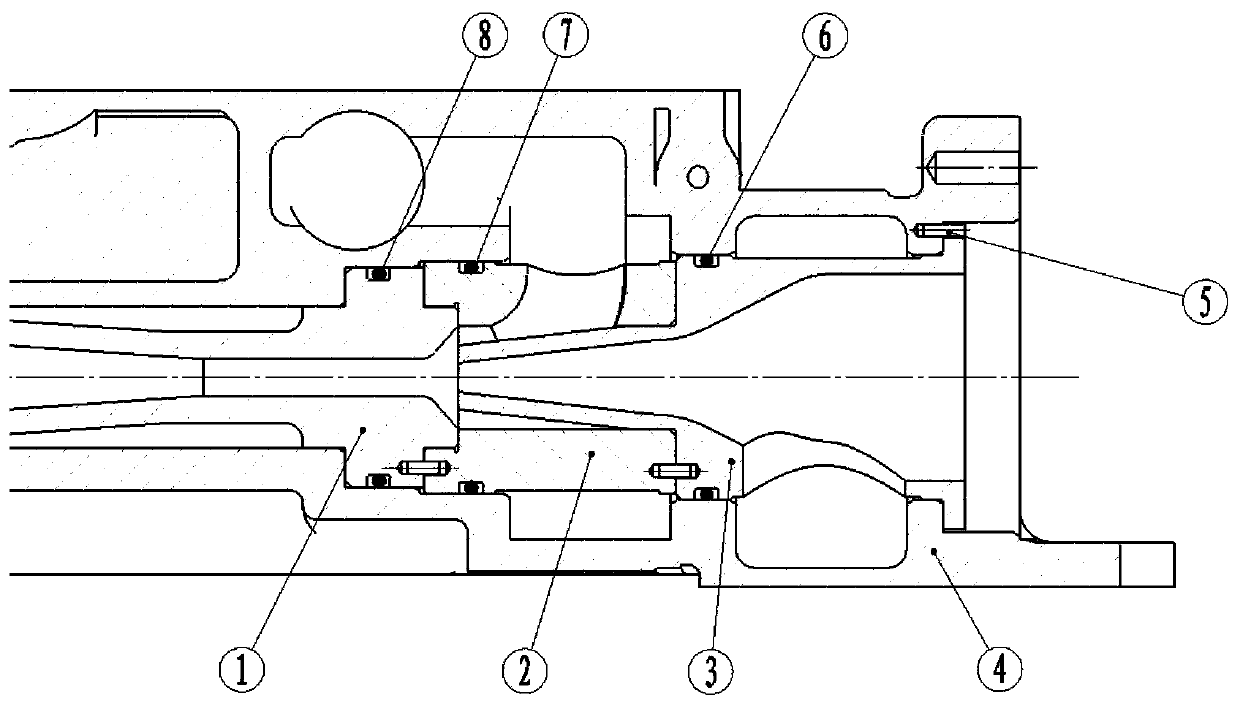

[0028] The invention provides a method for assembling a plurality of shaft parts with angular requirements in a deep hole. The method includes the following steps:

[0029] 1) Determine the position of the pin hole on the shell assembly when the last shaft part among the multiple shaft parts is assembled in the deep hole of the shell assembly;

[0030] 2) Based on the position of the pin hole on the shell assembly, assemble the first shaft part among the multiple shaft parts in the deep hole of the shell assembly along the axial direction of the shell assembly;

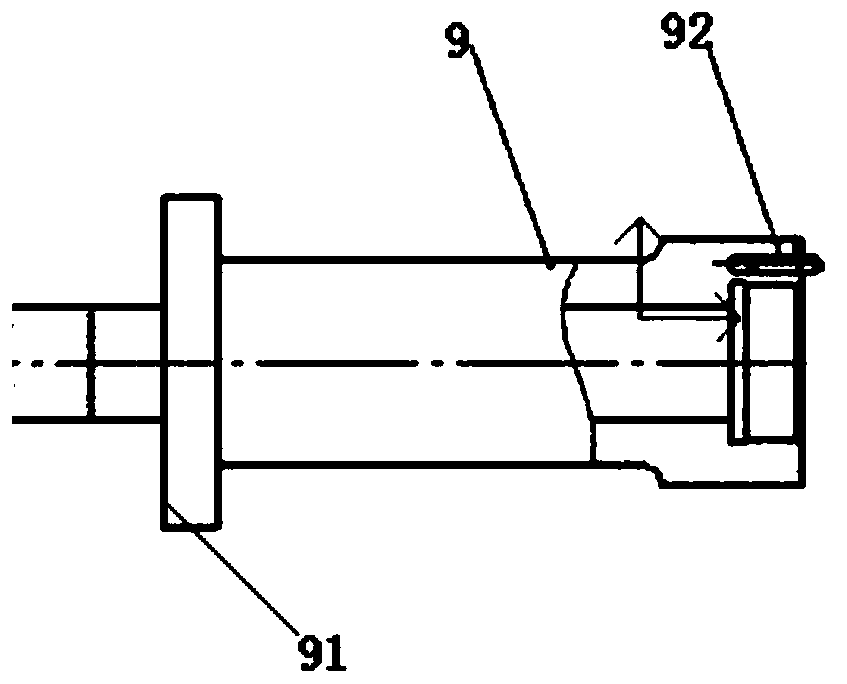

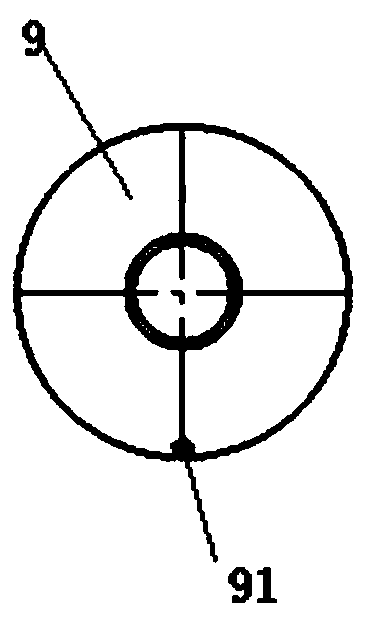

[0031] 3) Based on the position of the pin hole on the shell assembly, install the connecting pin at the end of the second shaft part, and extend the second shaft part into the deep hole of the shell assembly along the axial direction of the shell assembly , so that the end face of the second shaft part is in contact with the end face of the first shaft part and connected with the first shaft part through a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com