Large-span weak-rigidity gantry flexible hole forming device

A hole-making device and a large-span technology, applied in feeding devices, manufacturing tools, boring/drilling, etc., can solve the problems of high installation position of guide rails, poor stability, and reduced moving cost, so as to ensure local accuracy and stability The effects of high precision, precise control of hole making precision, and improvement of hole making precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

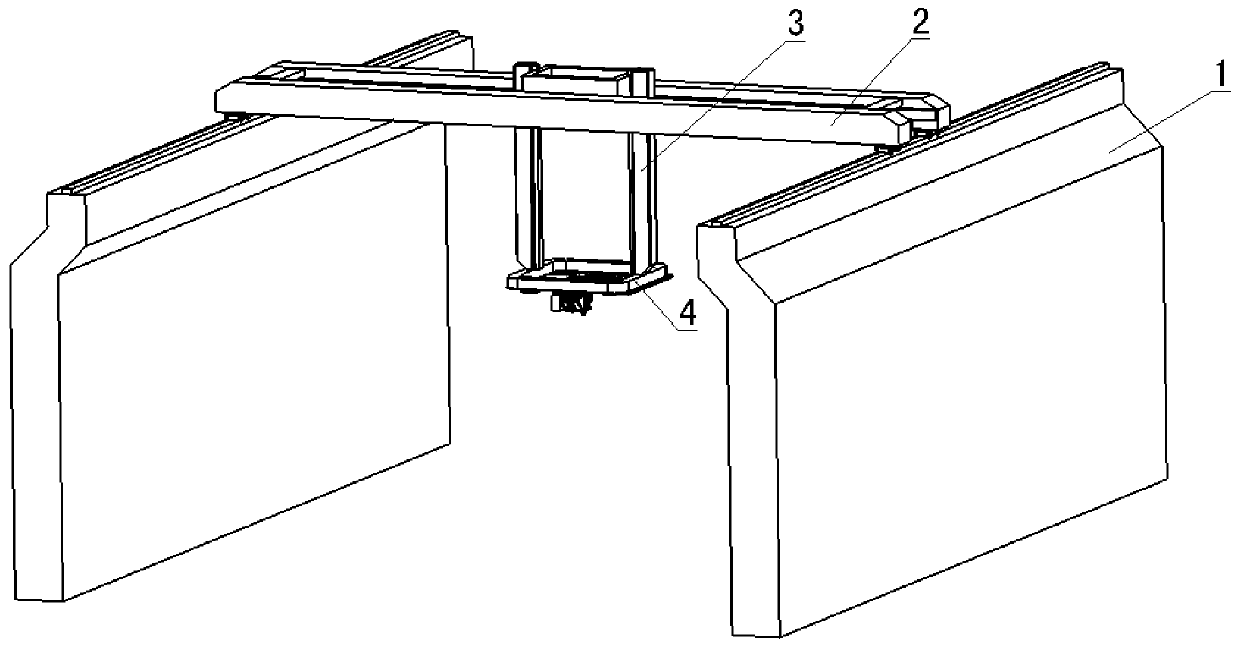

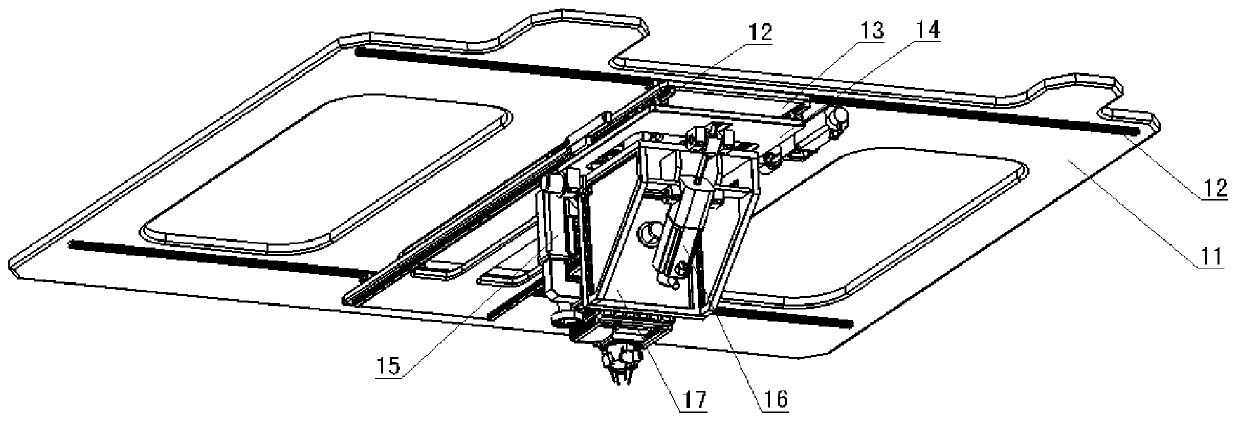

[0012] Referring to the accompanying drawings, the present invention is a device for realizing large-span gantry-type flexible drilling.

[0013] From figure 1 In the middle view, the supporting structure 1 and the sliding beam 2 are non-rigid bodies, which only provide a certain stability support for the mechanism. The two supporting structures 1 stand opposite each other, the sliding beam 2 spans the two supporting structures 1, and the lifting column 3 is fixed On both sides of the fixing seat 4, the fixing seat 4 is driven to move up and down in the vertical direction.

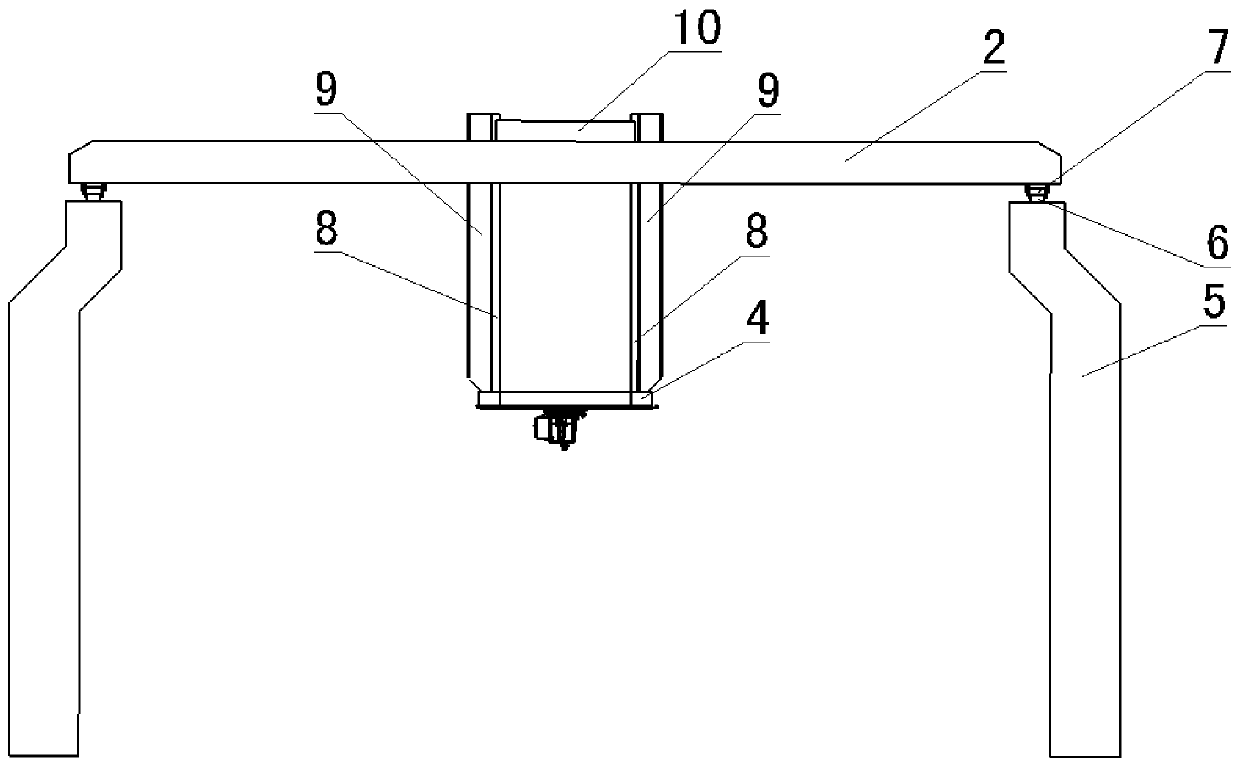

[0014] From figure 2 In the middle view, the two support structures 1 include a support body 5 and a square rail 6, the square rail 6 is installed on the top end surfaces of the two support bodies 5, the sliding beam 2 is a frame structure, spanning the two support bodies 5, and the bottom Both ends are provided with pulleys 7 that cooperate with the square rail 6, and can slide along the support body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com