Molten salt cleaning method

A cleaning method and molten salt technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of molten salt environmental pollution and difficult cleaning of molten salt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

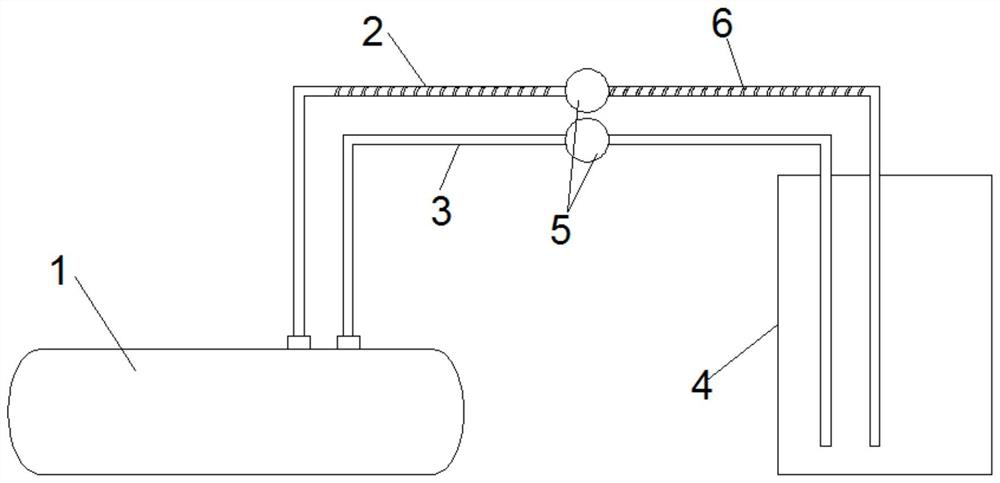

[0028] according to figure 1 As shown, a molten salt cleaning device includes: a molten salt tank 1, a first pipeline 2, a second pipeline 3 and a water tank 4, and the molten salt tank 1 passes through the first pipeline 2 and the second pipeline 3 communicates with the water tank 4, the first pipeline 2 and the second pipeline 3 are provided with a circulation pump 5, and the outer wall of the first pipeline 2 is provided with a heater 6.

[0029] The molten salt tank is communicated with the water tank through the first pipeline and the second pipeline, and the heater 6 heats the water flowing out to the first pipeline in the water tank; A circulating pump is arranged on the second pipeline, and the water heated by the first pipeline is input into the molten salt tank by using the circulating pump, and when the heated hot water flows into the molten salt tank, the hot water flows into the molten salt tank The molten salt block attached to the inner wall is heated and melte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com