Saturated steam decontamination device

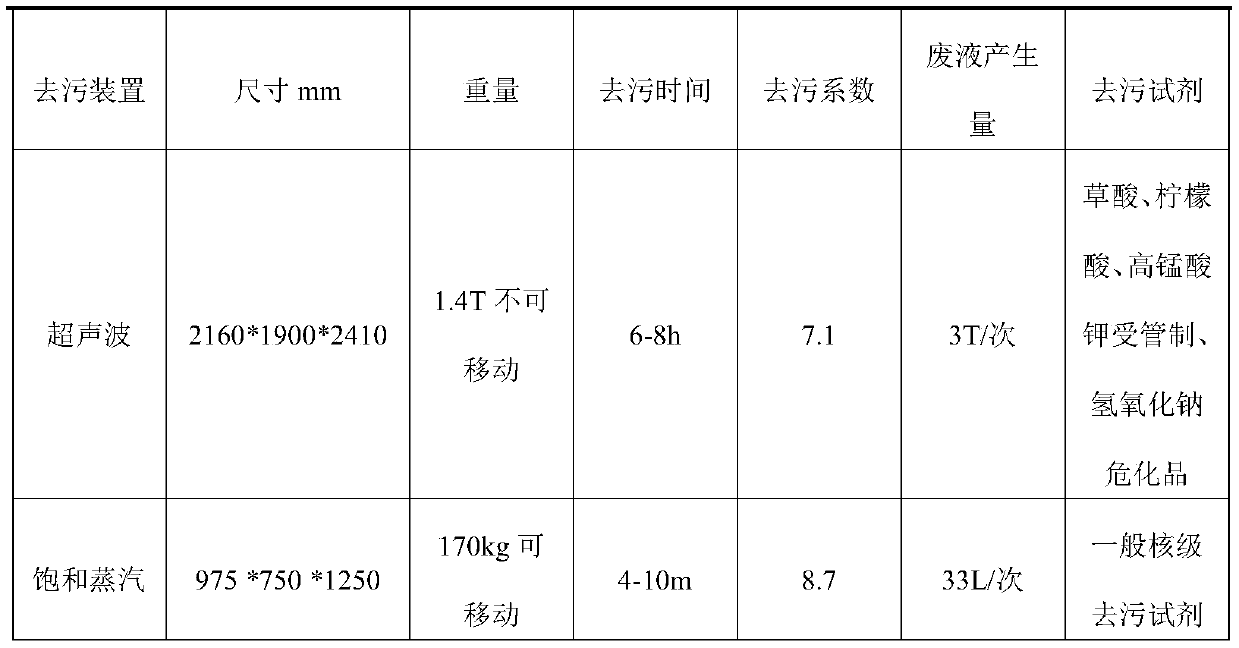

A decontamination device and steam technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of inflexible use, large volume, and long decontamination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

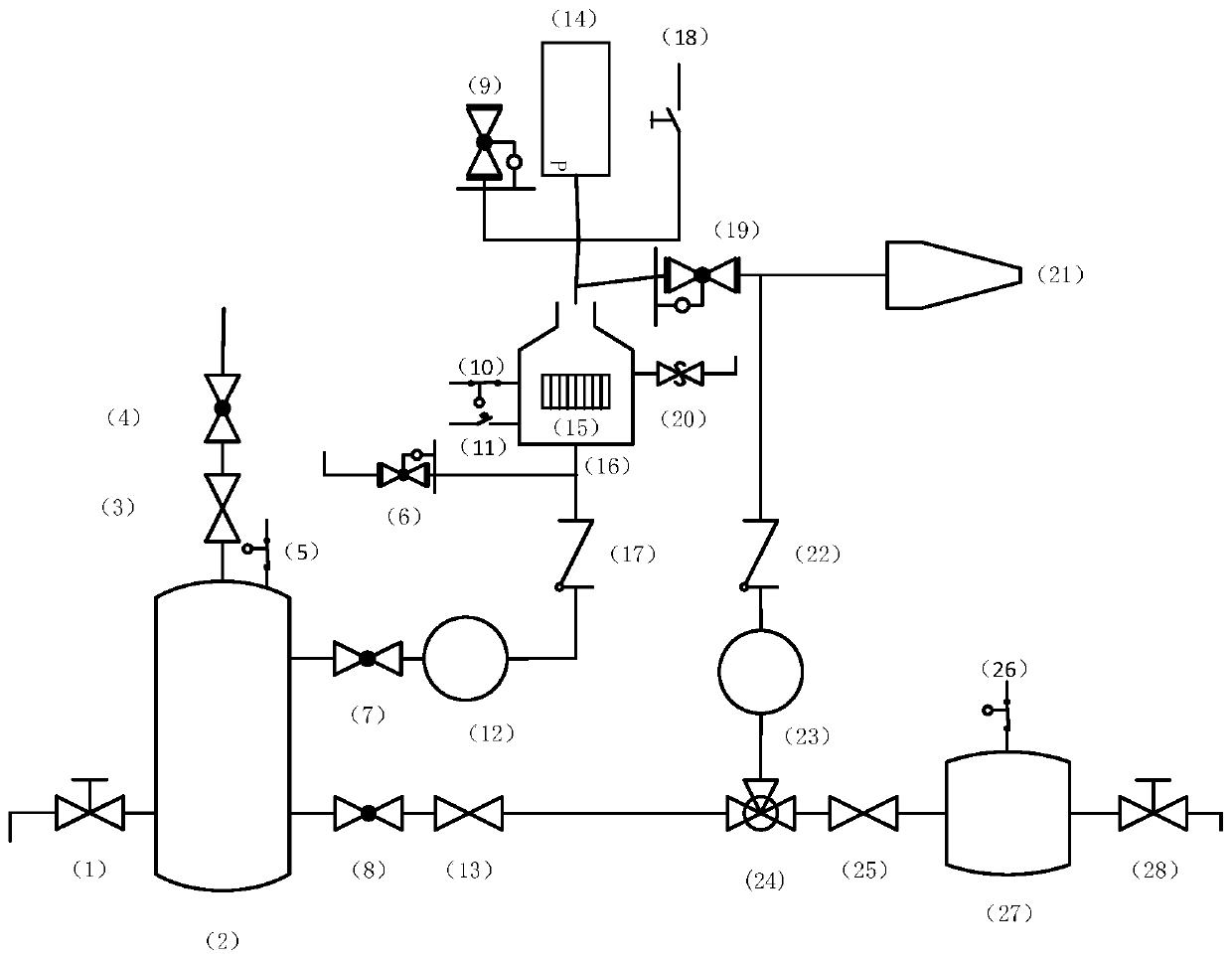

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] A saturated steam decontamination device is composed of four parts: a medicine box decontamination reagent part, a water tank part, a heating boiler part, and a water gun part. Deionized water is heated to become saturated steam at 180°C and 10 bar, combined with decontamination reagents, and sprayed from a water gun to produce a decontamination effect.

[0042] The main function of the medicine box part is to hold the decontamination reagent used in the decontamination process, and the decontamination reagent is mixed with saturated steam through the liquid medicine pump to complete the decontamination work. If there is no need to use decontamination reagents, this part can be isolated separately and only use saturated steam for decontamination;

[0043] The main function of the water tank is to hold the deionized water that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com