Ceramic tile cement smearing device for architectural decoration

A ceramic tile and cement technology, which is applied in the direction of construction and building construction, etc., can solve the problems of low efficiency of manual application, uneven manual application, and affecting the flatness of tile laying, so as to improve the quality of laying, improve the fixing effect, and improve the quality of cement. The effect of application amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

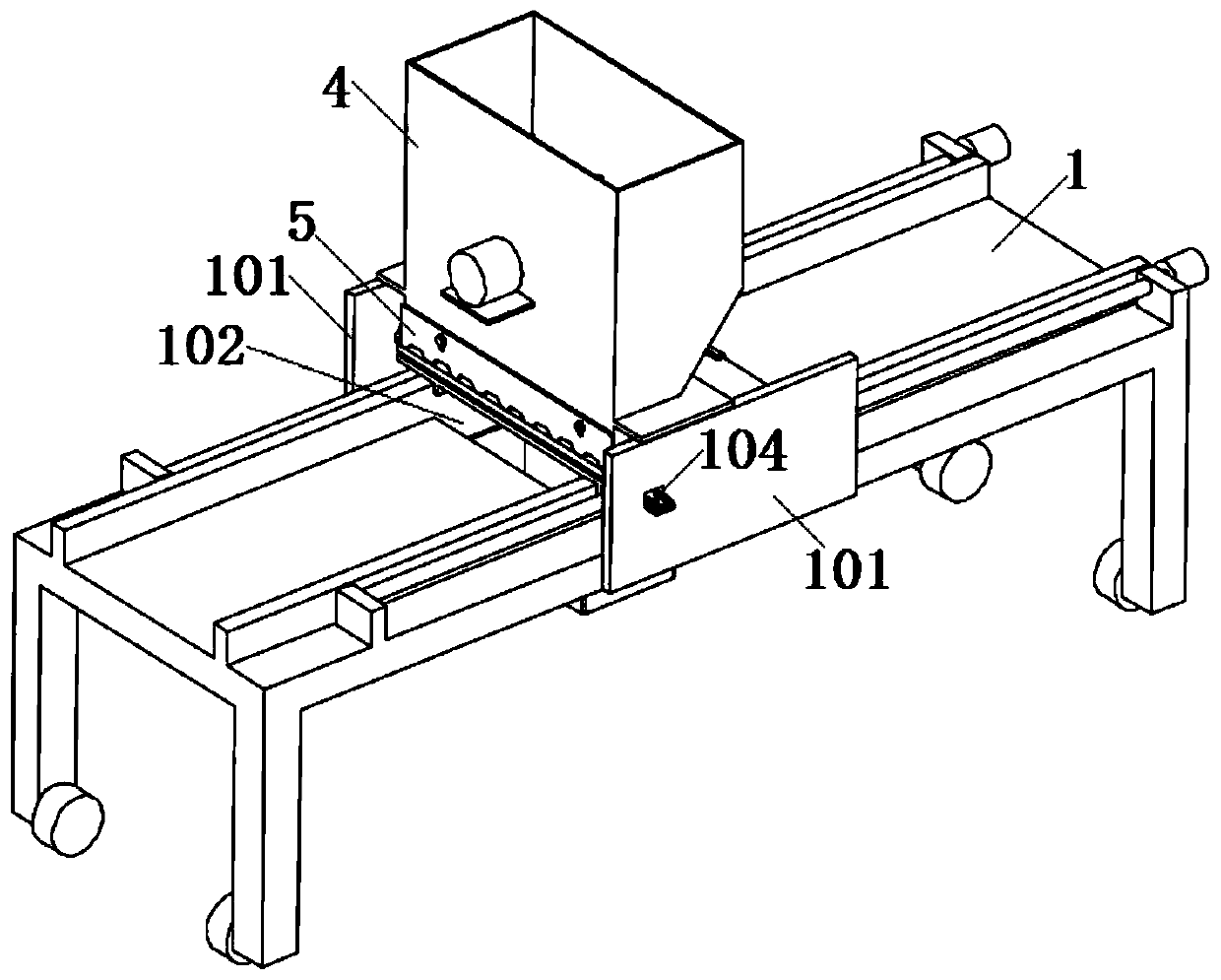

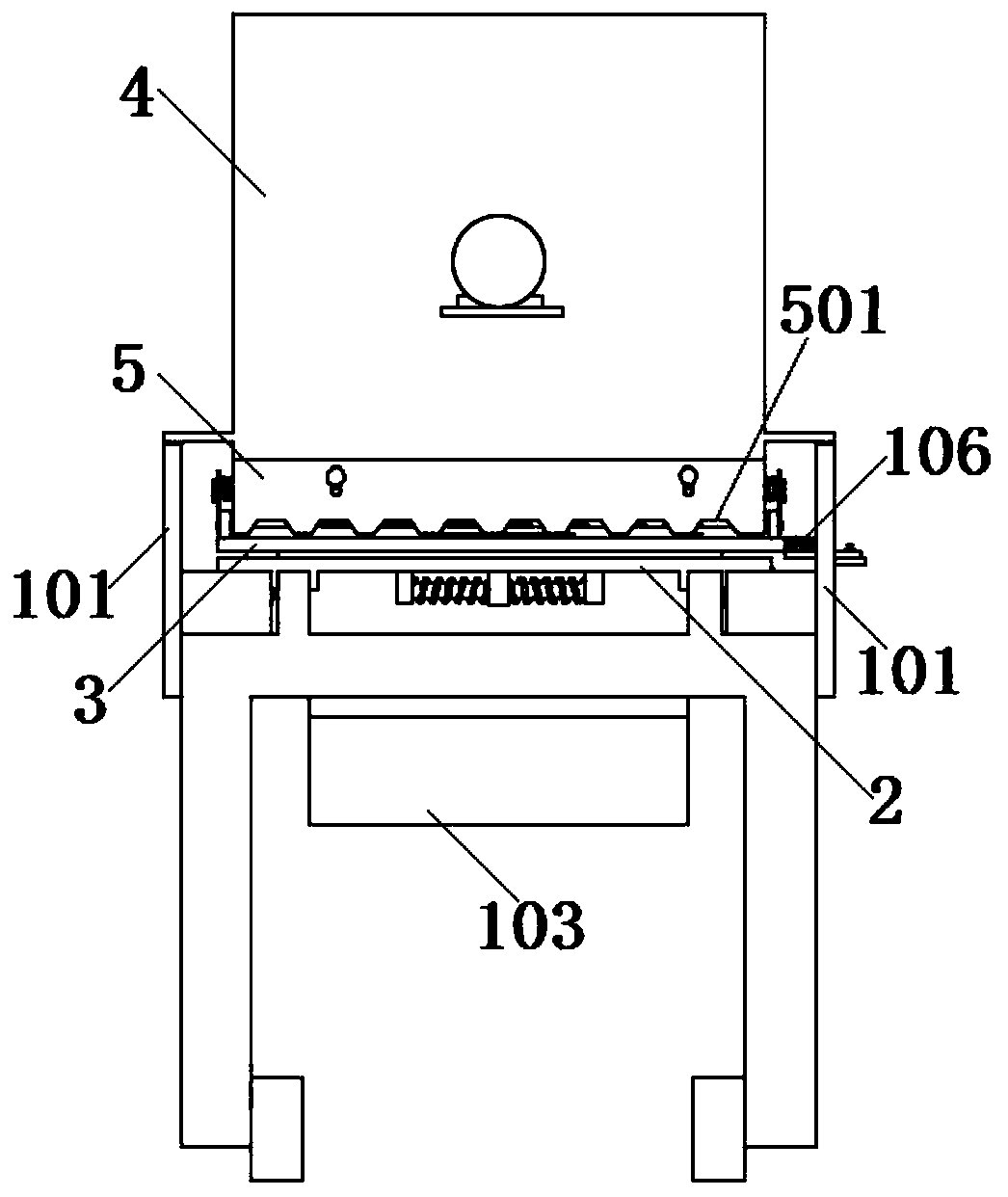

[0035] see figure 1 and 2 As shown, the present invention is a ceramic tile cement application device for building decoration, including a frame; universal wheels are installed on the supporting legs of the frame to facilitate the movement of the frame, so that it can move flexibly according to the construction position. The upper surface of the frame is welded and bolted, and the rectangular mounting plate 1 is installed with two parallel guide rails in the length direction of the upper surface, and the sliding plate 2 is slidably connected to the sliding plate 2 through the guide rail slider mechanism, so that the sliding plate 2 runs along the length direction of the mounting plate 1. Swipe up.

[0036] Such as Figure 7 and 8 As shown, the upper surface of the sliding plate 2 is connected with a smearing platform 3; the opposite side of the mounting plate 1 is fixedly connected with a side plate 101; the two side plates 101 are fixedly connected with a mixing bucket 4 b...

Embodiment 2

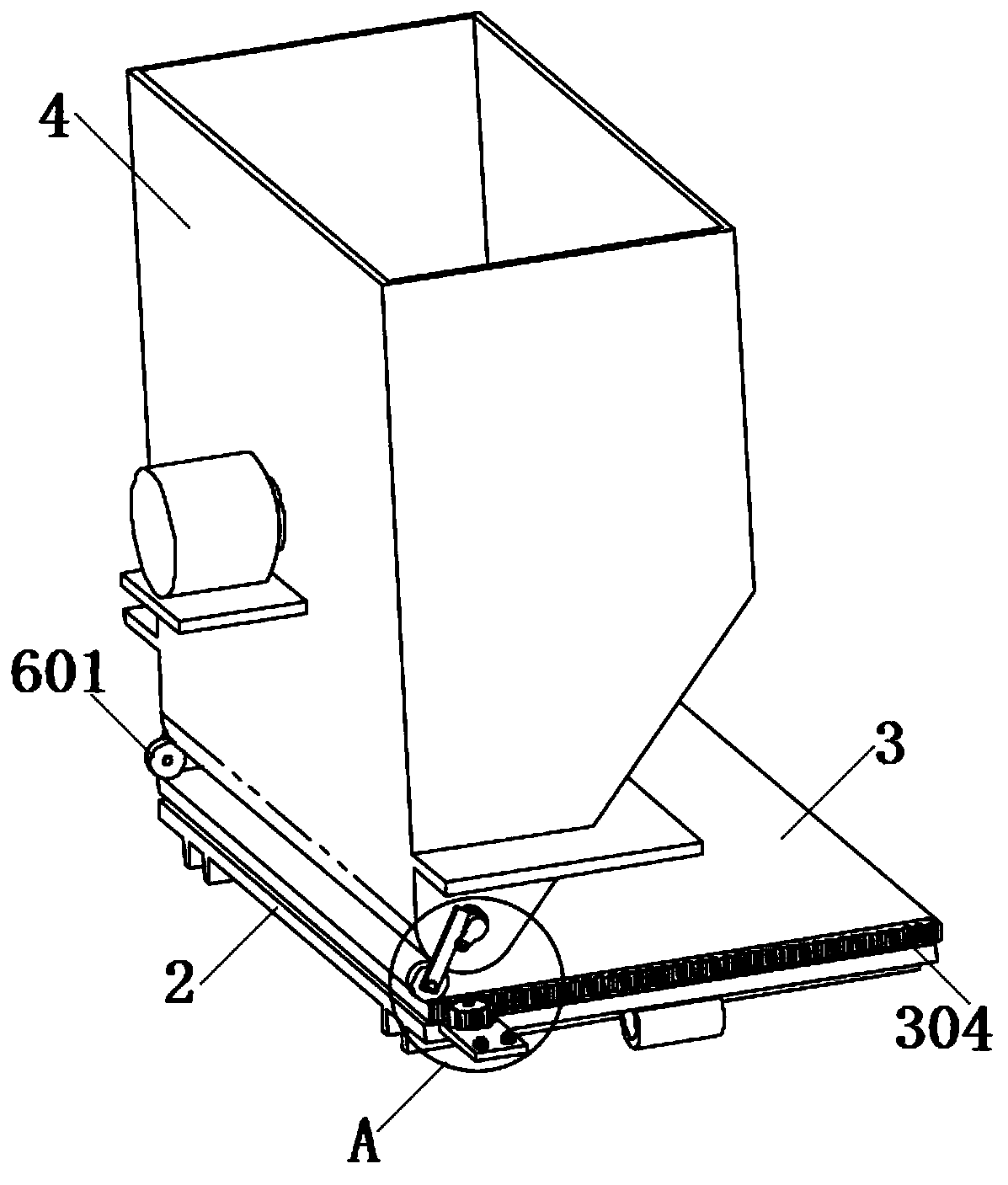

[0049] On the basis of Example 1, as Figure 7 and 8 As shown, the sliding plate 2 is connected to the smearing platform 3 by sliding, such as a guide rail slider mechanism, a slider chute mechanism, etc., and the sliding direction of the smearing platform 3 is perpendicular to the sliding direction of the sliding plate 2 on the mounting plate 1 .

[0050] The surface of the sliding plate 2 is provided with a straight notch 201; the lower surface of the sliding plate 2 is symmetrically welded with two connecting plates 202 relative to the straight notch 201; a guide rod 203 is welded or threaded between the two connecting plates 202; Two return springs 204 are sleeved.

[0051] The lower surface of the smearing platform 3 is welded with a limit block 303; the lower end of the limit block 303 runs through the straight notch 201, and is provided with a through hole for clearance fit with the guide rod 203; the limit block 303 is located between the two return springs 204, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com