Box-type bridge prestressed tendon accurate alignment installation device and installation method thereof

A technology of prestressing tendons and installation devices, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as cumbersome operation, rework during traction, and occupying space in reserved holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the text of the specification. The presence or addition of one or more other elements or combinations thereof is not excluded.

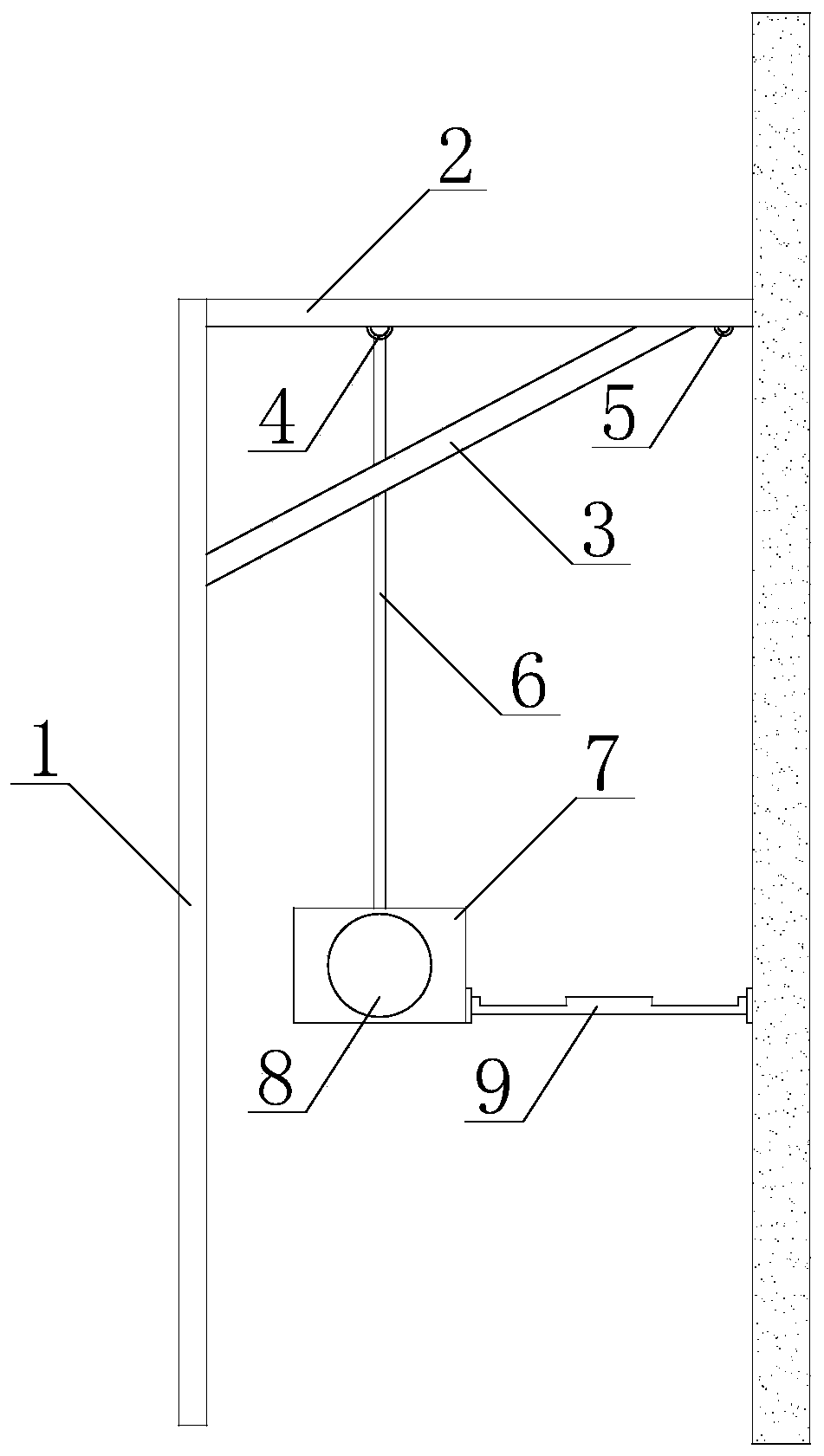

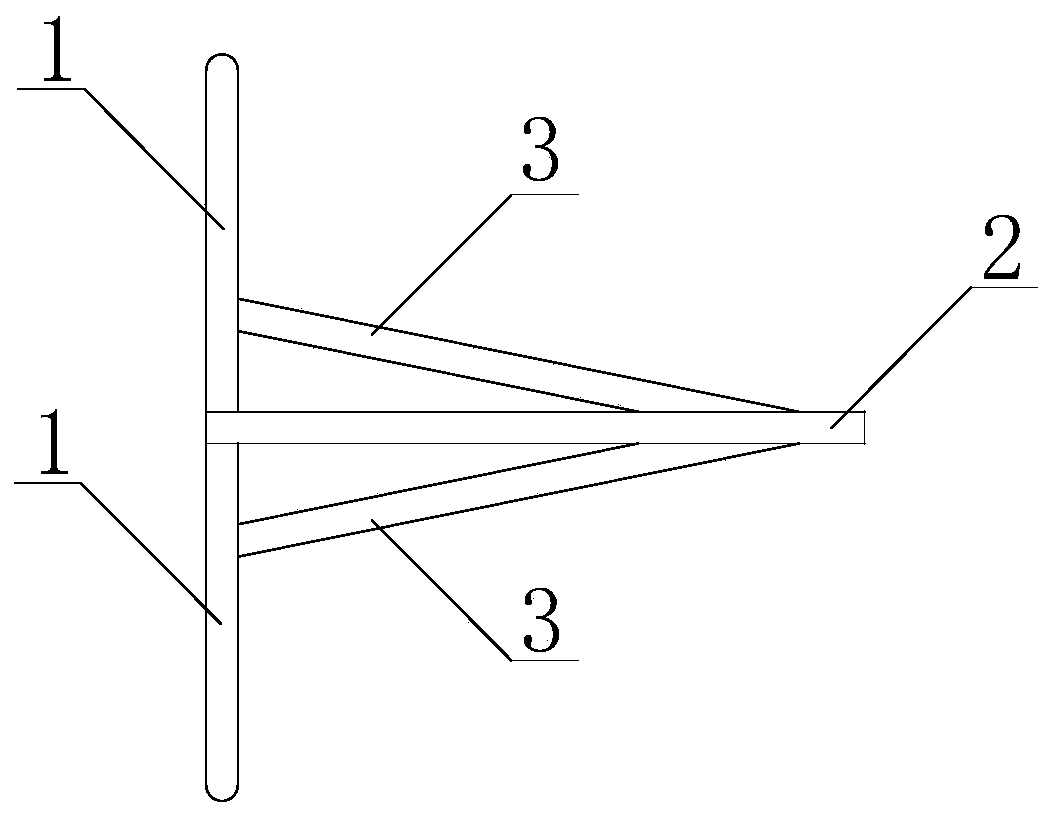

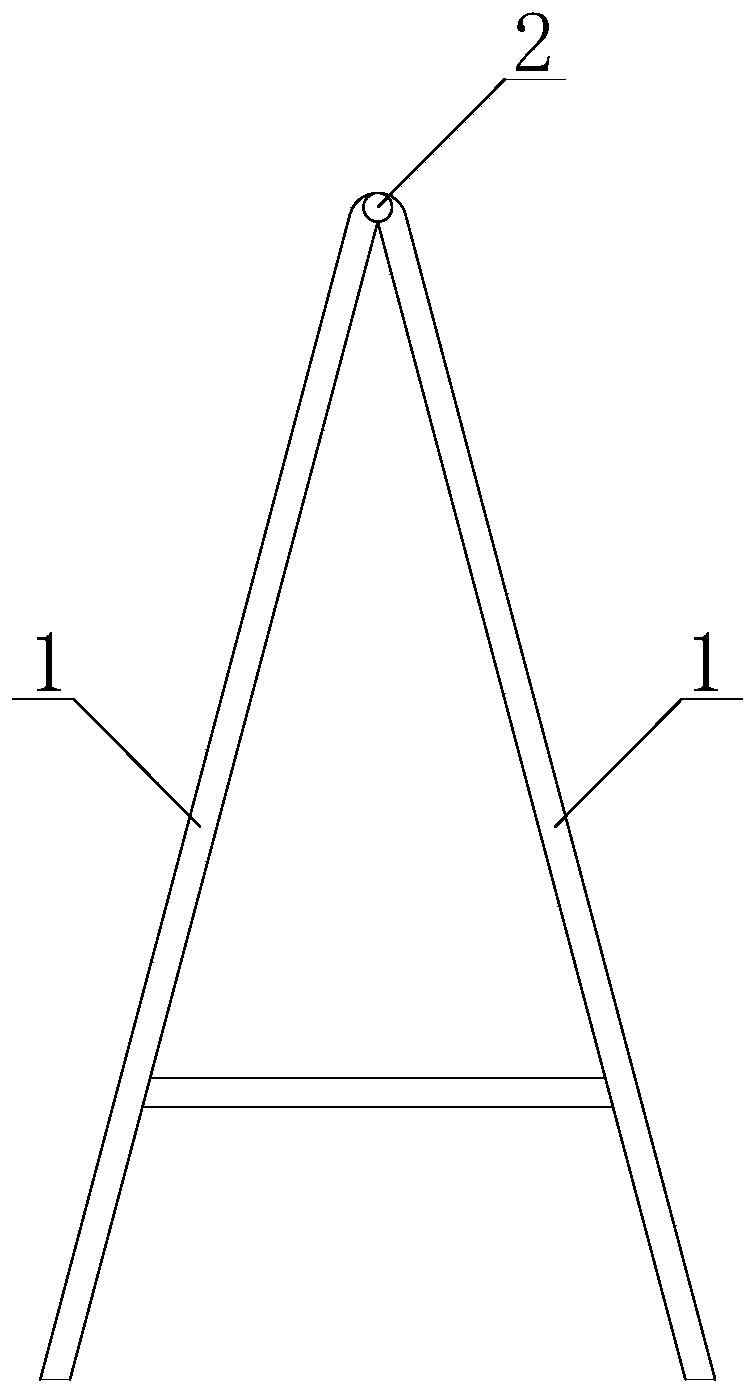

[0023] Such as Figure 1 ~ Figure 4 As shown, the present invention provides a precise alignment installation device for prestressed tendons of a box-shaped bridge, including a portal frame, an upper beam 2, a threading device, a wire conduit 9, and a tapered lead head. The portal frame is an inverted "V" The font structure, the upper beam 2 is welded to the top of the portal frame; the threading equipment is composed of a power motor 8 and a threader 7, the threading equipment is connected to the portal frame through the hanging chain 6, and the wire is set between the threading equipment and the reserved hole Pipe 9 and wire conduit 9 are made of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com