A method for comprehensive utilization of oilfield associated gas

A technology for oilfield associated gas and condensate oil, which is used in the petroleum industry, gas fuel, liquid hydrocarbon mixture recovery and other directions, can solve the problems of difficult transportation, low concentration, liquefaction or high pressure transportation, etc., to achieve comprehensive utilization of resources, realize The effect of diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Taking a certain project as an example, the components of associated gas in the oilfield are as follows:

[0055]

[0056] Oilfield associated gas temperature: 37°C, pressure: 440kPa.

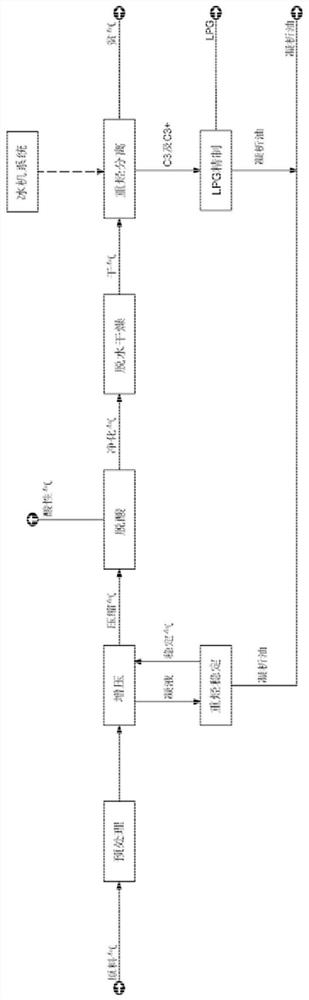

[0057] according to figure 2 As shown in the process, the specific process is as follows:

[0058] (1) The associated gas in the wellhead oilfield enters the first-stage pressurization process after pretreatment to remove sand and dehydration. The outlet pressure of the first-stage pressurization process is 2500kPa; The 490kPa lean gas produced by the hydrocarbon stabilization process is returned to the first-stage pressurization process, and the butane content in the condensate produced by the heavy hydrocarbon stabilization process is controlled at about 2%. C5 and C5+ are recovered as condensate oil after being stabilized by heavy hydrocarbons.

[0059] (2) The compressed gas after the first-stage pressurization enters the first-stage dehydration and drying process for dehydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com