Device and method for measuring flexoelectric coefficient of thin film material with adjustable strain gradient

A technology of flexoelectric coefficient and strain gradient, applied in the field of electromechanical coupling, can solve problems such as the influence of flexoelectric measurement results, achieve the effect of simple and easy experimental equipment, avoid uneven strain gradient, and realize the effect of position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples, but it is not intended to limit the present invention.

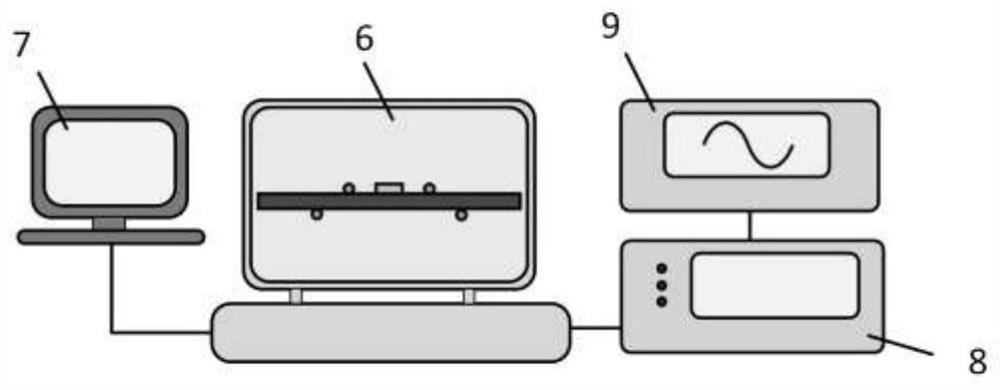

[0031] like figure 1 and figure 2 As shown, a device for measuring the flexoelectric coefficient of thin film materials with adjustable strain gradients in the present invention includes an upper substrate beam 1-1 and a lower substrate beam 1-2 with the same length, width and thickness, and an upper substrate beam 1-2 arranged between the two layers of beams. A sandwich structure formed by a test film 2 with the same length and width as the beam, a four-point 1 / 4 bending fixture composed of two upper indenters 5 and two stressed supports 4, loaded with a four-point 1 / 4 bending fixture The small load loading instrument 6, the controller 7 connected with the small load loading instrument 6 to control loading force and loading frequency, the charge amplifier 8 connected with the small load l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com