Novel aerosol fogging oil tank

An aerosol, a new type of technology, applied in the direction of detecting the appearance of fluid at the leak point, measuring device, suspension and porous material analysis, etc., can solve the problem of reducing the accuracy of photometer leak detection method, affecting the performance of aerosol generator, Difficult to adjust the oil mist concentration and other problems, to achieve the effect of preventing oil mist backflow, stable fogging effect, and convenient oil mist concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

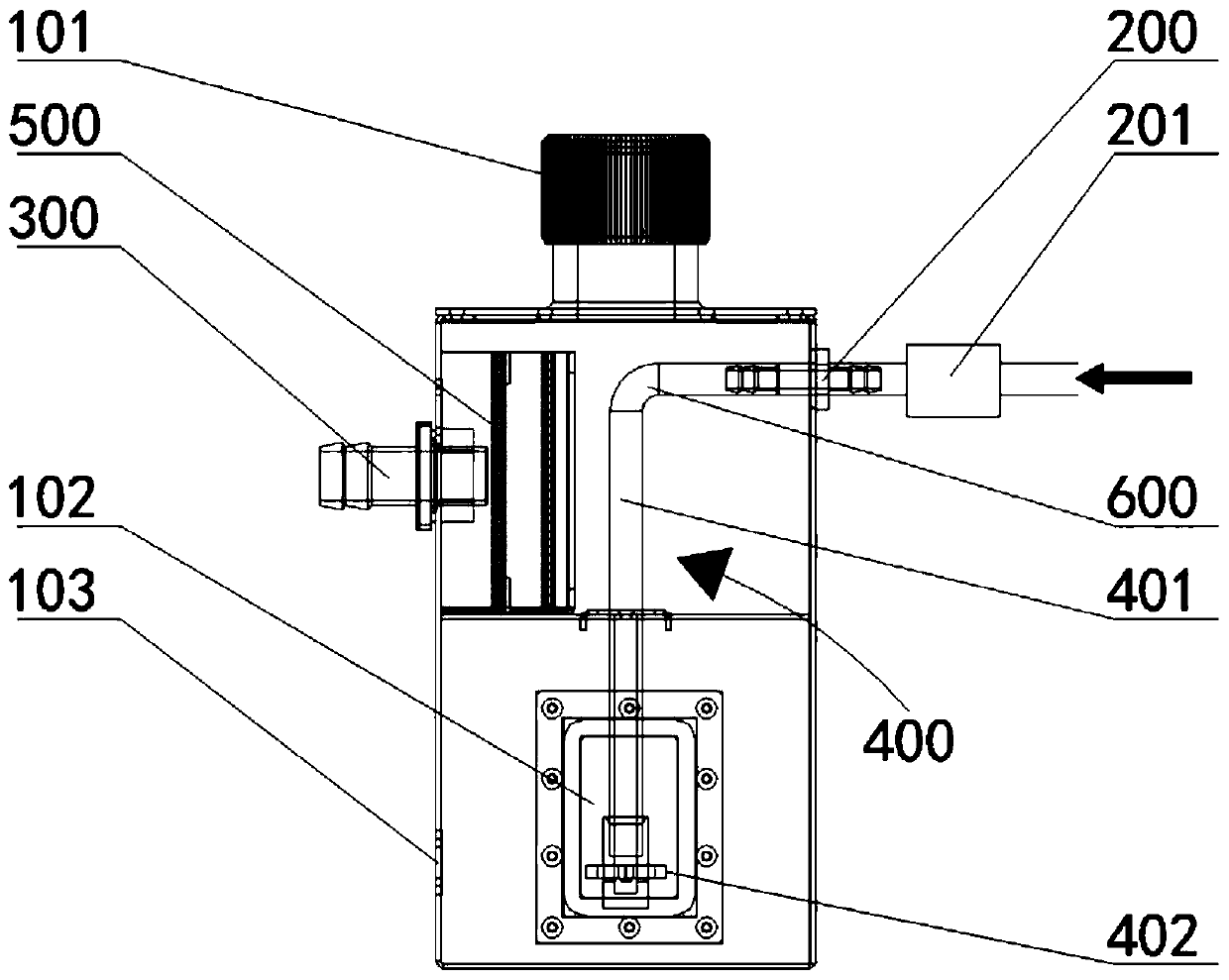

[0026] The up and down directions described in the present invention refer to figure 2 In the up and down directions, the left and right directions described in the present invention refer to figure 2 in the left and right directions.

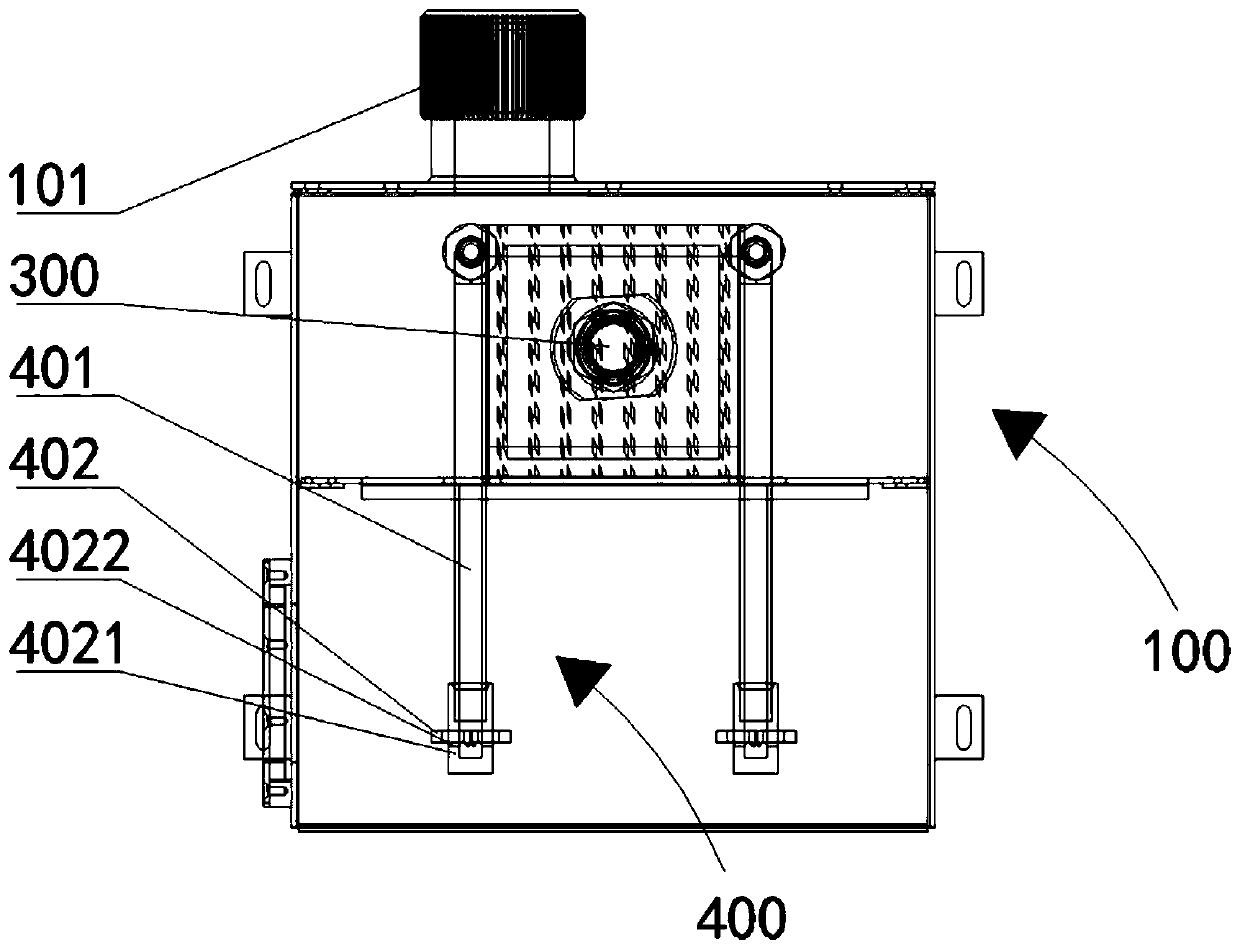

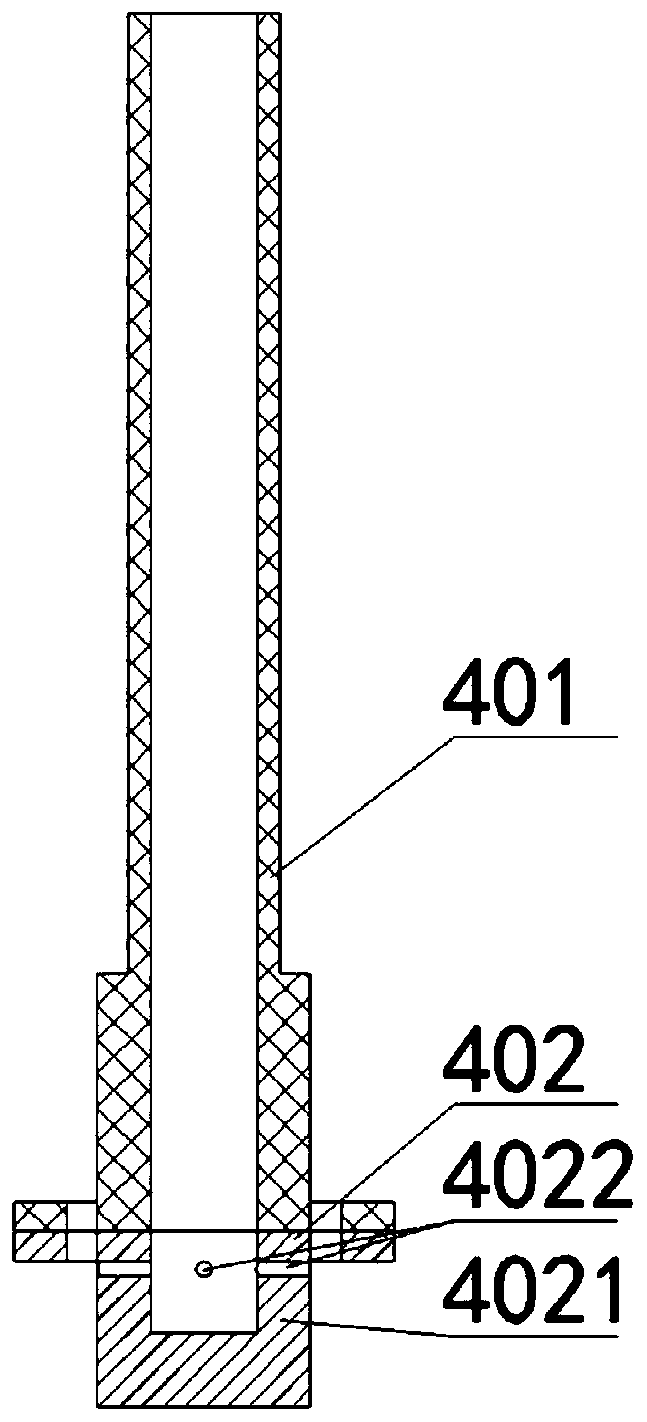

[0027] Such as Figure 1-3 As shown, the novel aerosol fogging oil tank provided by the present invention includes: a box body 100, a clean air inlet nozzle 200, an oil mist outlet nozzle 300, a Ruskin nozzle 400, a filter baffle 500, and an oil-resistant pipe 600, wherein, The upper part of the right side wall of the box body 100 is provided with two air inlets, the clean air inlet nozzle 200 is pierced at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com