A temperature-resistant and salt-resistant jelly foam containing phosphonic acid structure and its preparation method and application

A temperature-resistant, salt-resistant, and jelly-resistant technology, which is applied in the direction of chemical instruments and methods, and drilling compositions, can solve the problems of easy dehydration and degradation, and cannot achieve selective water blocking, and achieve enhanced cross-linking density. , good water plugging selectivity, and the effect of enhancing salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

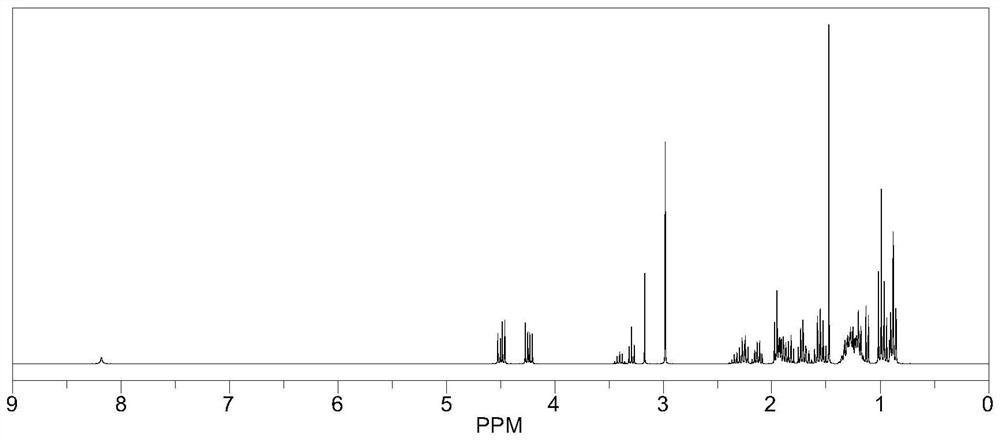

[0056] A method for preparing a temperature-resistant and salt-resistant carbon dioxide gel foam for oil field water plugging, comprising the following steps:

[0057] 1) Weigh 5.0g of N,N-dimethylacrylamide, 36.85g of isooctyl acrylate (salt-tolerant monomer), 10.4g of 2-acrylamide-2-methylpropanesulfonic acid monomer, 5.56 g of N-vinylpyrrolidone and 200 mL of acetone solvent were transferred to a four-necked flask placed in a constant temperature water bath, and then nitrogen gas was passed into the four-necked flask for 10 minutes to remove oxygen, and then heated under magnetic stirring at a heating temperature of 50°C .

[0058] When the temperature was raised to 70°C reaction temperature, 0.36g of benzoyl peroxide (BPO) initiator was added. After the initiator was dissolved in 20mL of acetone solution, it was slowly added dropwise through a constant pressure dropping funnel, and the reaction was continued at this temperature for 6h , To obtain a temperature-resistant a...

Embodiment 2

[0063] As shown in Example 1, the difference is that each component mass percent in step 2) becomes the following ratio:

[0064] 0.6% heat-resistant and salt-resistant polymer, 0.5% resorcinol, 0.5% hexamethylenetetramine, 0.5% octylphenol ethoxylate, 0.5% phenylphosphonic acid, 0.4% Sulfite. The balance is water.

Embodiment 3

[0066] As shown in Example 1, the difference is that the phenols in step 2) are changed to pyrocatechol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com