Transverse moving and feeding mechanism

A technology of traversing and decelerating motors, which is applied in the direction of conveyors, conveyor objects, rollers, etc., and can solve the problems of inflexible relative positions, inflexibility, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

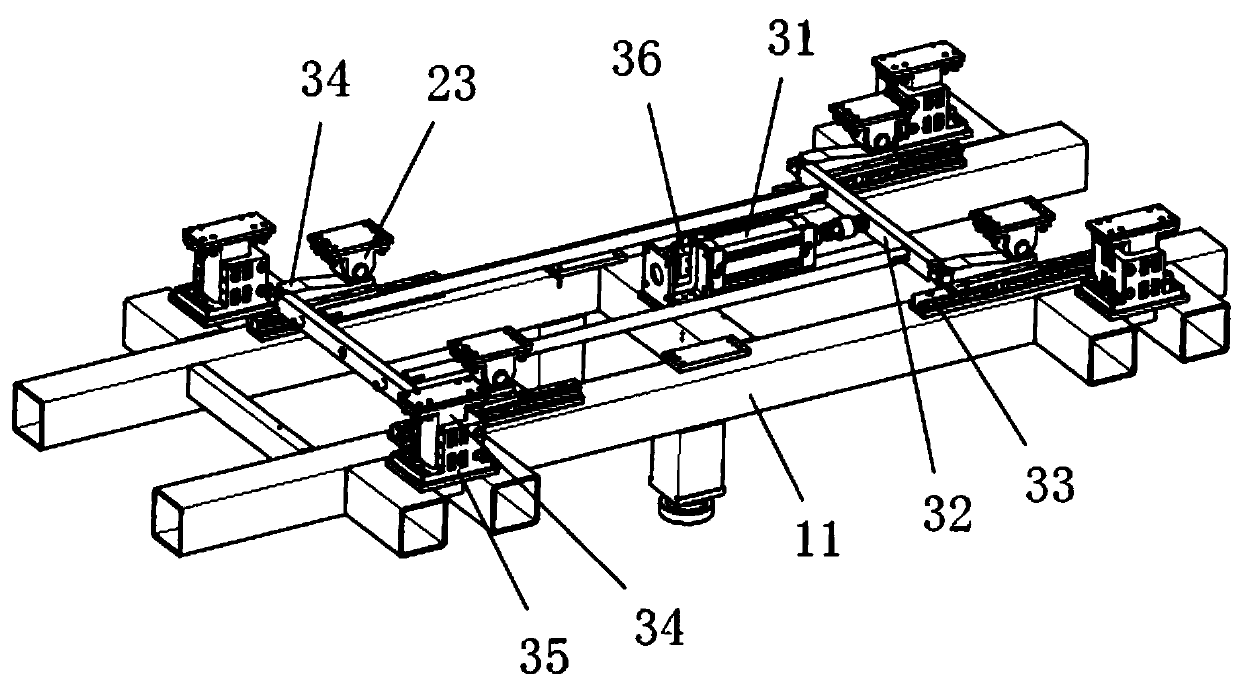

[0013] Such as Figure 1-2 As shown, a traversing feeding mechanism according to the present invention includes a base 11, a traversing drive device, a lifting frame 22 and a lifting drive assembly; the lifting drive assembly includes a forward moving cylinder 31 and a forward connecting frame 32, The forward connecting frame 32 is made up of two connecting plates and two connecting rods, both ends of the two connecting plates are provided with lifting seats 34, and the base 11 is provided with four forward sliding rails 33 which cooperate with the lifting seats 34 , the forward cylinder 31 drives the lifting seat 34 to slide along the forward slide rail 33 through the forward connecting frame 32; the four corners of the bottom of the lifting frame 22 are provided with lifting rollers 23, and the lifting seat 34 is provided with lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com