Pressure boost gas water heater and control method

A gas water heater and supercharger technology, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of affecting the speed of hot water output for users' bathing experience, gas water heaters that cannot work normally, and gas water heaters that cannot start normally and other issues, to achieve the effect of improving the bathing experience, improving the user experience, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

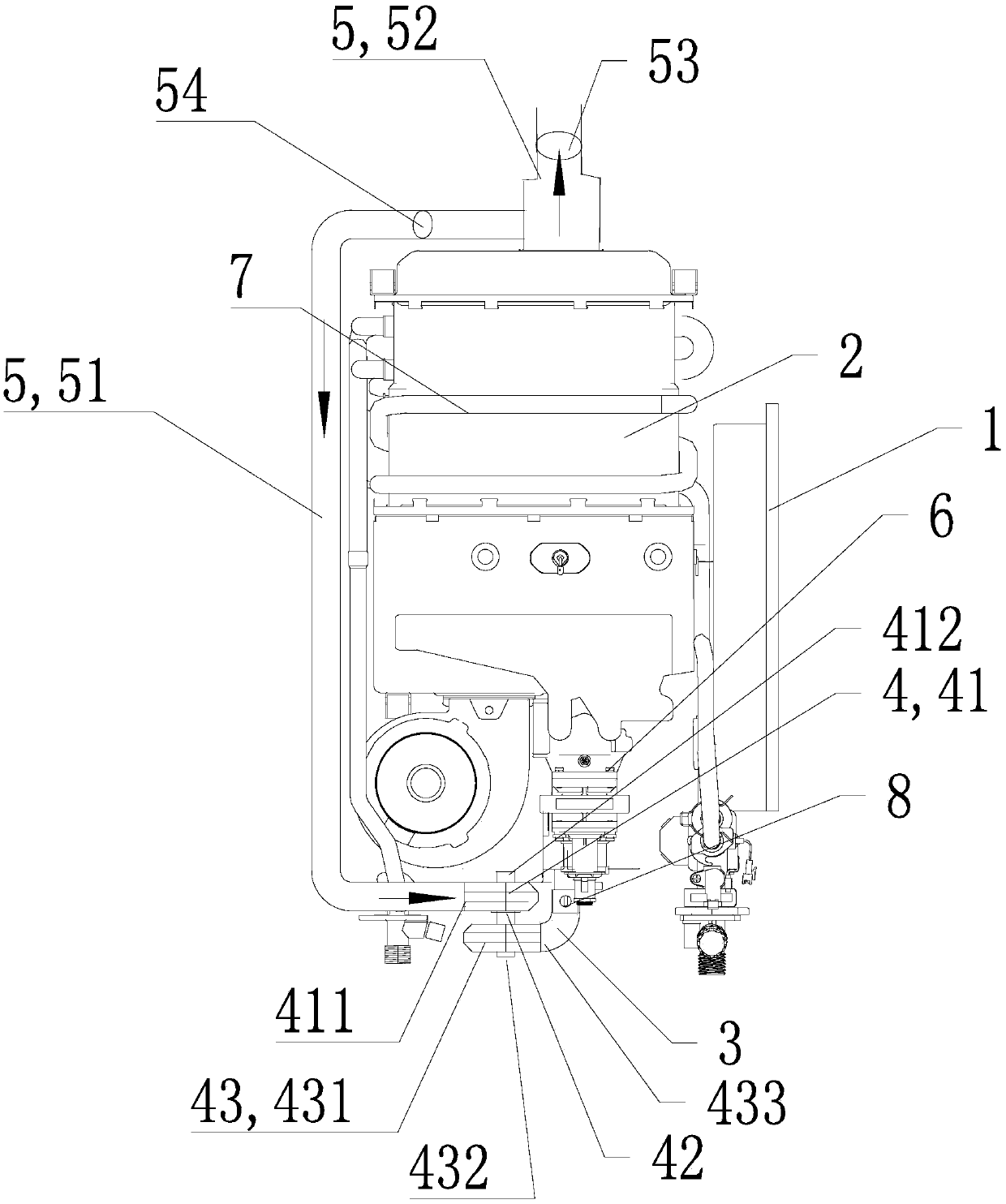

[0038] Such as figure 1 As shown, the present embodiment provides a pressurized gas water heater, including a combustion chamber 2 and a gas intake pipeline 3, the gas intake pipeline 3 is connected to the combustion chamber 2, and the gas enters the combustion chamber 2 for combustion, and also includes a The turbocharger 4 on the gas intake pipeline 3, the exhaust gas pipeline 5 is arranged between the combustion chamber 2 and the turbocharger 4, the exhaust gas in the combustion chamber 2 enters the turbocharger 4 through the exhaust pipeline 5 and drives The turbocharger 4 operates to supercharge the gas.

[0039] In this embodiment, the gas water heater with pressurization function includes a heat exchange device 7, a combustion chamber 2, and a gas intake pipeline 3, the gas intake pipeline 3 is connected to the combustion chamber 2, and the gas enters the combustion chamber 2 and burns to form a heat exchange device 7 Provide heat source. Pass water such as tap water or...

Embodiment 2

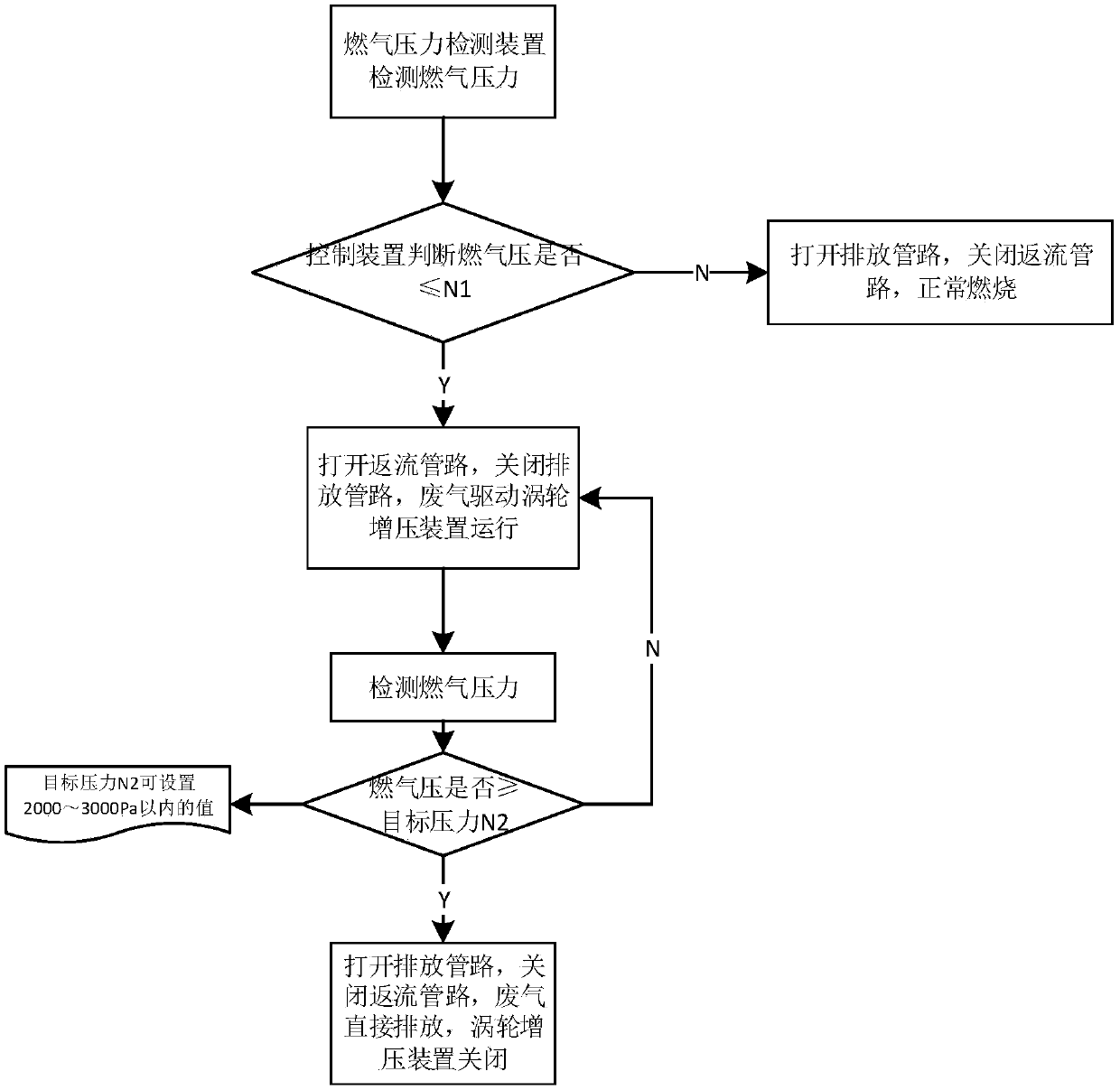

[0056] Such as figure 2 As shown, this embodiment is a further limitation of Embodiment 1, and provides a control method for a supercharged gas water heater. The gas water heater controls the flow direction of the exhaust gas according to the pressure value of the gas detected by the gas pressure detection device 8, and controls the turbocharging. The opening / closing of the device 4 carries out / stops pressurizing the gas. In this way, the energy of the exhaust gas can be used again, and the pressure of the intake gas can be accurately controlled to ensure the stability of the gas intake pressure. It is suitable for various combustion conditions, ensures the temperature and stability of the outlet water, and greatly improves the user's bathing experience.

[0057] Specific programs include:

[0058] When the gas pressure detection device 8 detects that the real-time intake gas pressure value N is lower than the preset value N1, it transmits a signal to the control device 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com