Transcritical CO2 closed circulation system

A circulatory system, transcritical technology, applied in the direction of machines/engines, steam engines, mechanical equipment, etc., can solve the problems of low cycle efficiency and narrow operating range of generator/drive units, so as to improve cycle efficiency and avoid unstable unit operation. , the effect of increasing the volume flow of the intake air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

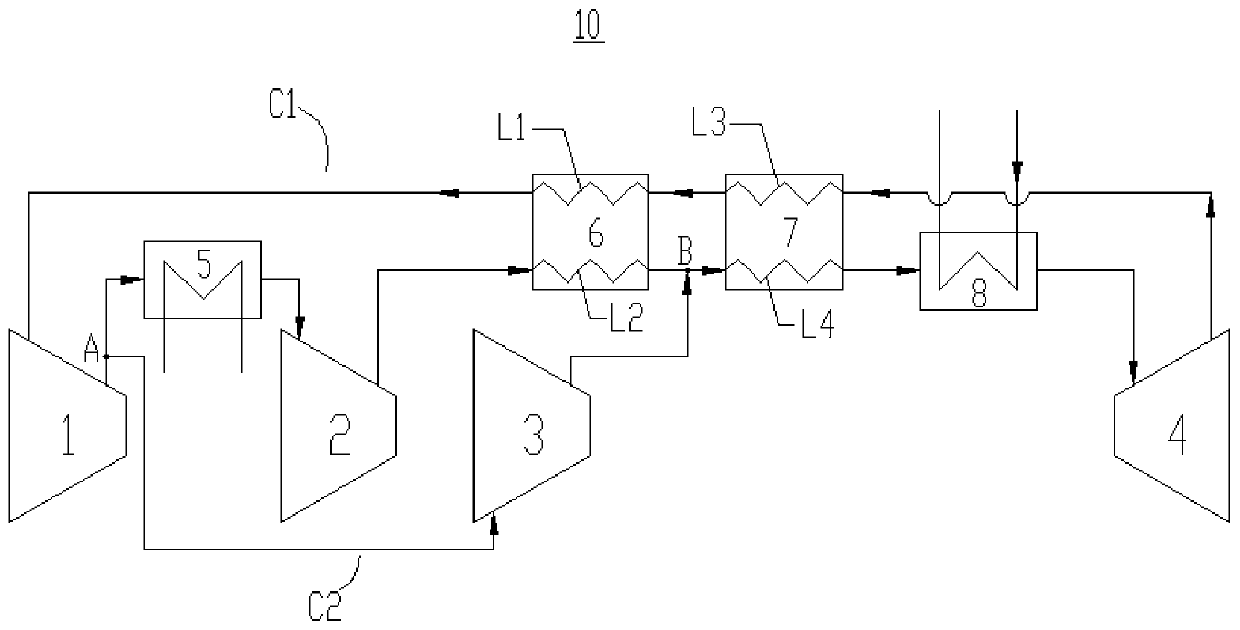

[0036] Please refer to figure 1 , this embodiment provides a transcritical CO 2 A closed cycle system 10 includes a pre-compressor 1 , a main compressor 2 , a re-compressor 3 , a turbine 4 , a cooler 5 , a low-temperature regenerator 6 , a high-temperature regenerator 7 and a heater 8 .

[0037] Wherein, the low temperature regenerator 6 has a first channel and a second channel, the first channel is used as the hot end of the low temperature regenerator 6, and the second channel is used as the cold end of the low temperature regenerator 6; the high temperature regenerator 7 has a third channel and the fourth channel, the third channel is used as the hot end of the high temperature regenerator 7, and the fourth channel is used as the cold end of the low temperature regenerator 6.

[0038] In this embodiment, the outlet of the pre-compressor 1 is connected to the cooler 5, the outlet of the cooler 5 is connected to the inlet of the main compressor 2, the outlet of the main comp...

Embodiment 2

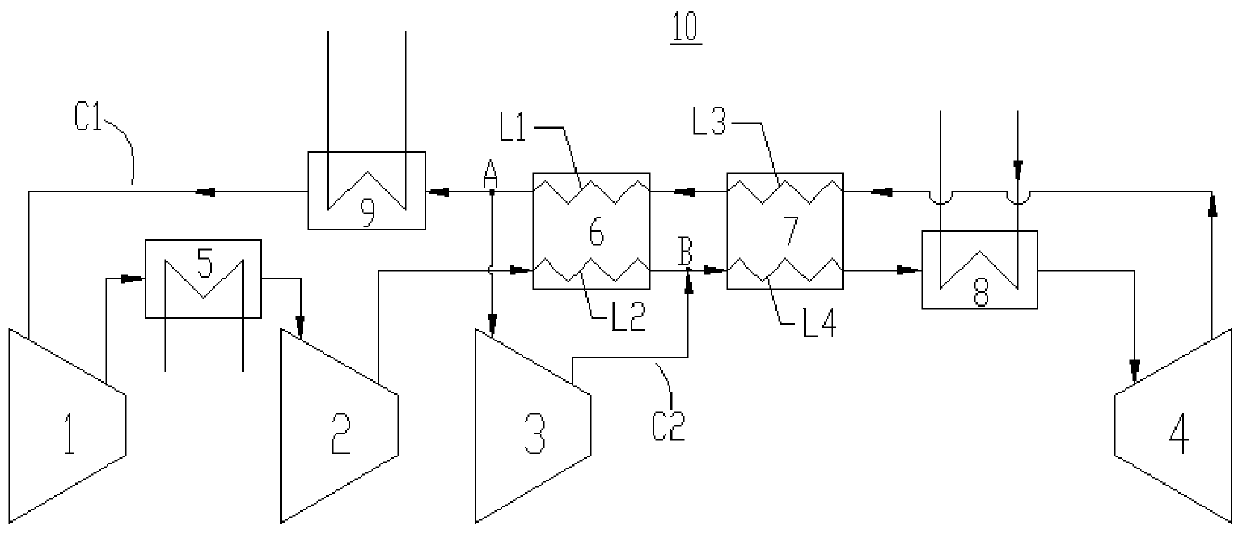

[0050] Please refer to figure 2 , this embodiment provides a transcritical CO 2 The closed circulation system 10 is different from the first embodiment in that the split point A is set between the inlet of the pre-compressor 1 and the outlet of the first channel. Furthermore, in closed CO 2 A second cooler 9 is additionally arranged in series on the circulation circuit C1, and the second cooler 9 is located between the outlet of the first channel and the inlet of the pre-compressor 1; the split point A is set between the outlet of the first channel and the second cooler 9 between the entrances.

[0051] The transcritical CO in this example 2 In addition to the beneficial effects corresponding to the closed circulation system 10 in Embodiment 1,

[0052] It is also possible to adjust the inlet temperature of the pre-compressor 1 by controlling the outlet temperature of the working medium of the additionally provided second cooler 9 to keep it within an appropriate range, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com