Filling pipe capable of effectively preventing materials from gushing out

A technology for filling tubes and materials, applied in packaging and other directions, can solve problems such as appearance wrinkles, poor use effect, and dents, and achieve good visual effects and full-bodied finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

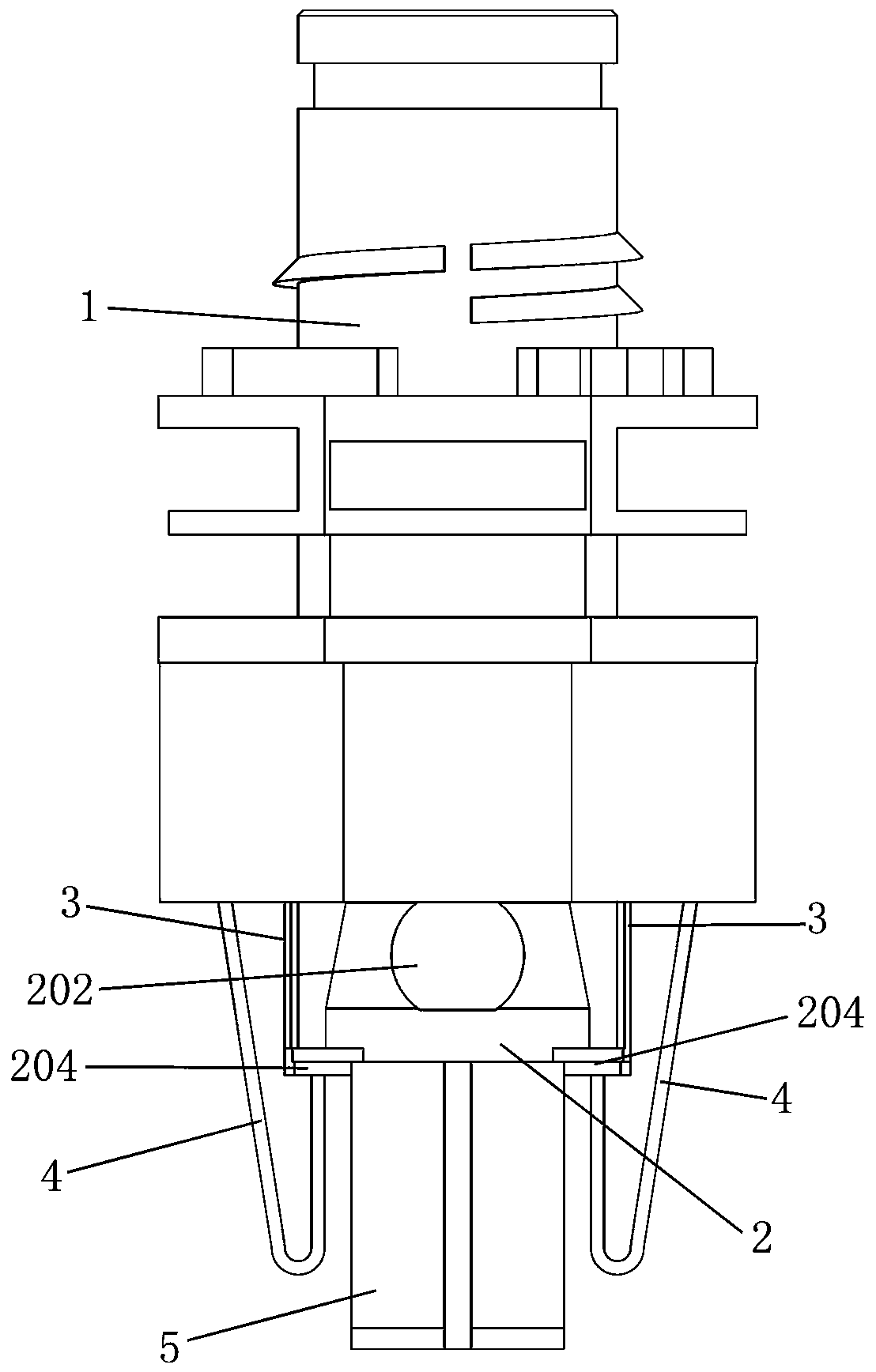

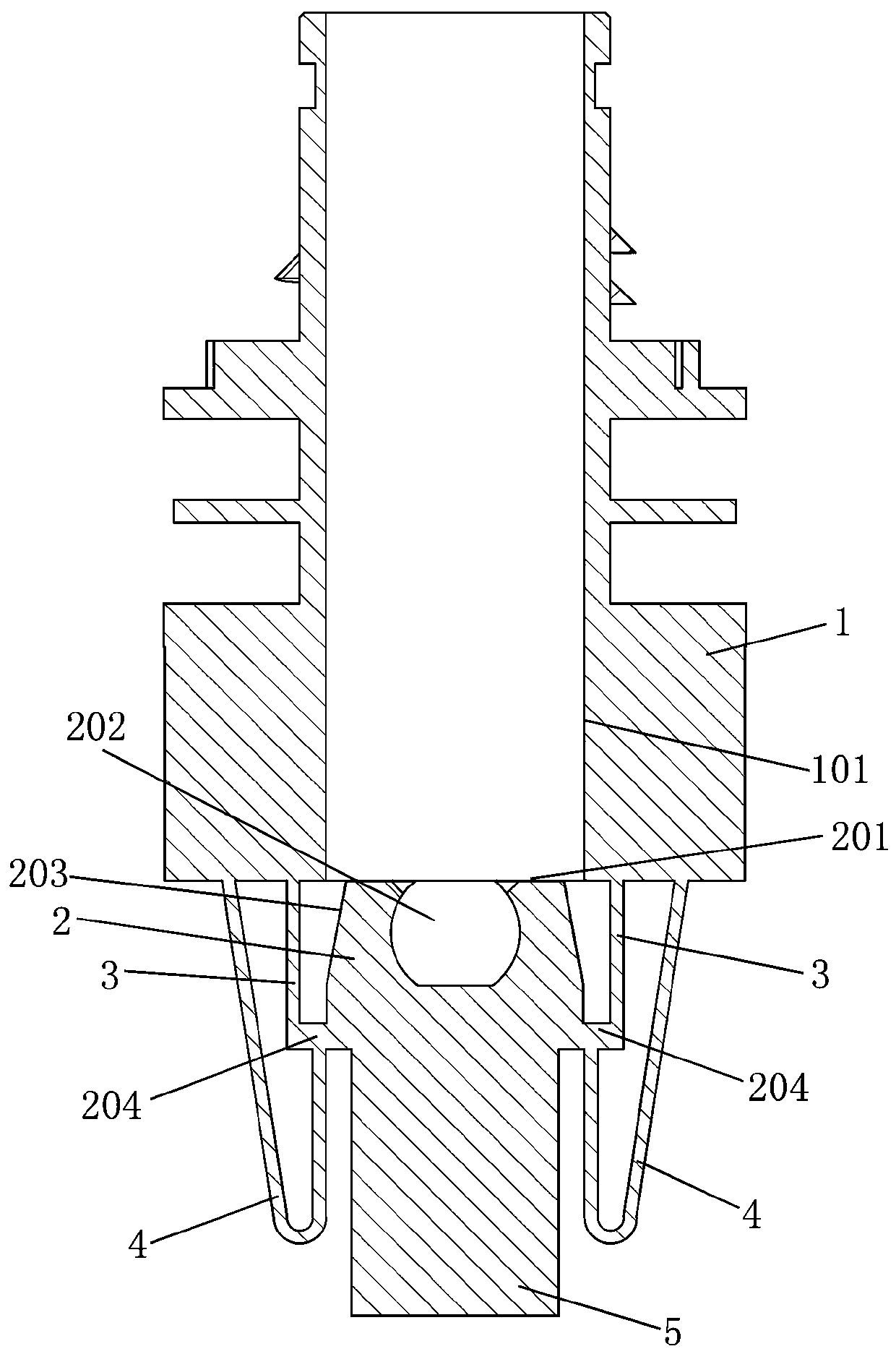

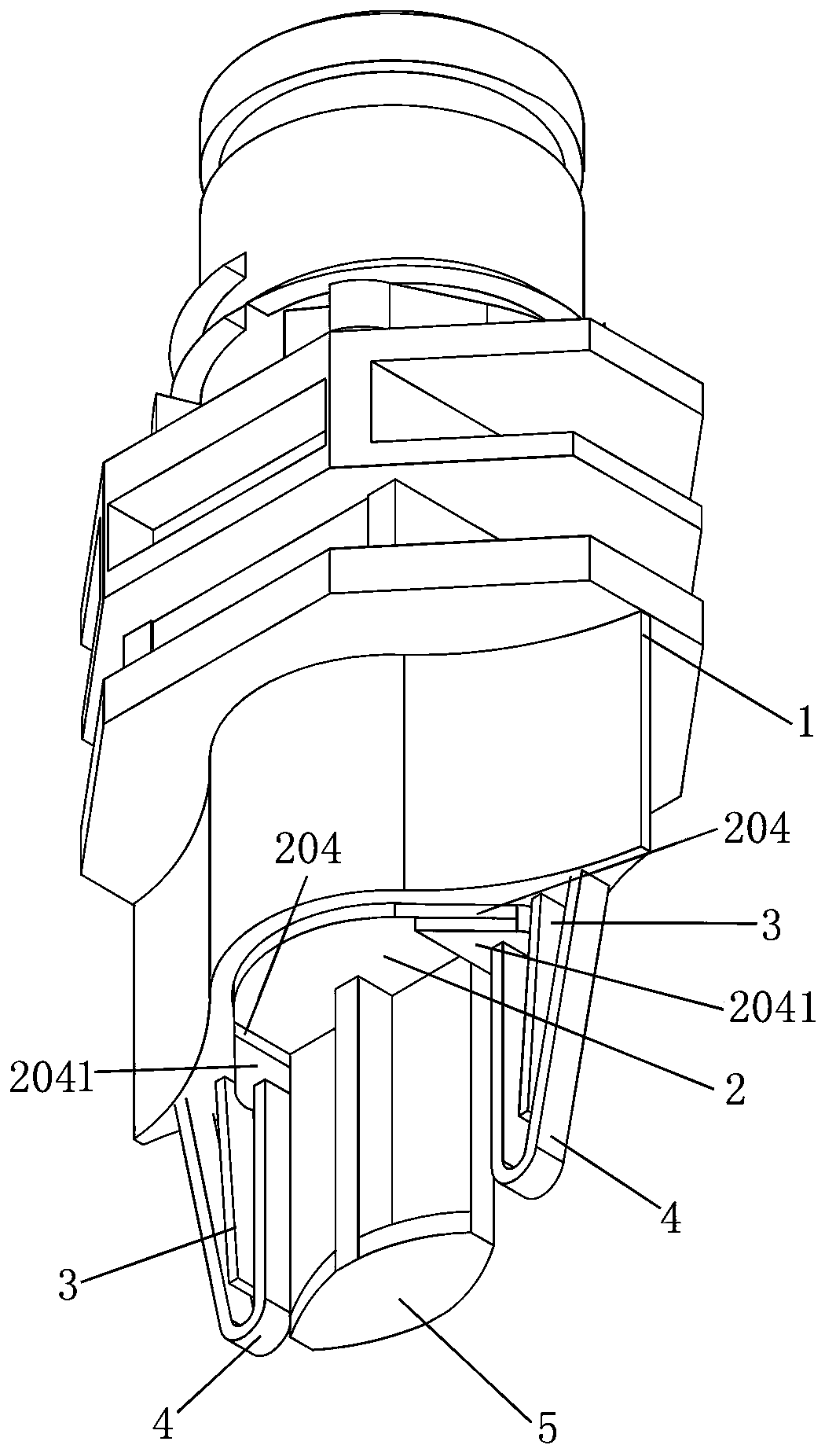

[0027] like Figure 1-8 As shown, the filling pipe in this embodiment that can effectively prevent materials from gushing out includes a filling pipe body 1 and a valve body 2. There is a filling channel 101 between the top and bottom surfaces of the filling pipe body 1, and the valve body 2 Connect the filling pipe body 1 through two breakable connecting wires 3, the two breaking connecting wires 3 are respectively located on the left and right sides of the filling pipe body 1, and the valve body 2 is located in the filling channel of the filling pipe body 1 Below the bottom opening of 101, there is a deformable ball pit 202 on the top surface 201 of the valve body; the bottom end of the outer surface 203 of the valve body 2 has two steps 204 that can be stuck at the bottom opening of the filling channel 101 of the filling pipe body 1 , the number of the steps 204 is two, and the two steps 204 are respectively located on the left and right sides of the valve body 2 . The ste...

Embodiment 2

[0039] The difference between the filling pipe that can effectively prevent the material from gushing out in this embodiment and that in Embodiment 1 is that:

[0040] The outer diameter of the outer surface 203 of the valve body 2 within 1 mm above the step 204 is equal to the inner diameter of the filling channel 101 .

[0041] The number of steps 204 is one, and the steps 204 extend along the circumference of the outer surface 203 of the valve body 2 to form a closed ring.

Embodiment 3

[0043] The difference between the filling pipe that can effectively prevent the material from gushing out in this embodiment and that in Embodiment 1 is that:

[0044] The outer diameter of the outer surface 203 of the valve body 2 located within 3 mm above the step 204 is equal to the inner diameter of the filling channel 101 .

[0045] The two stepped bottom surfaces 2041 of the valve body 2 are not designed to connect the valve line 4 nor the switch handle 5 . Therefore, before the consumer uses it, it is necessary to use a rod or stick to extend from the top of the filling channel 101 to poke the valve body 2 out from the bottom opening of the filling channel 101, which is inconvenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com