Shear fork arm flexible welding workstation

A technology for welding workstations and scissors, which is applied to welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of reduced welding efficiency, low pass rate, and easy occurrence of missing welding, so as to improve the efficiency of positioning and welding, and improve Consistency and pass rate, saving welding man-hours and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

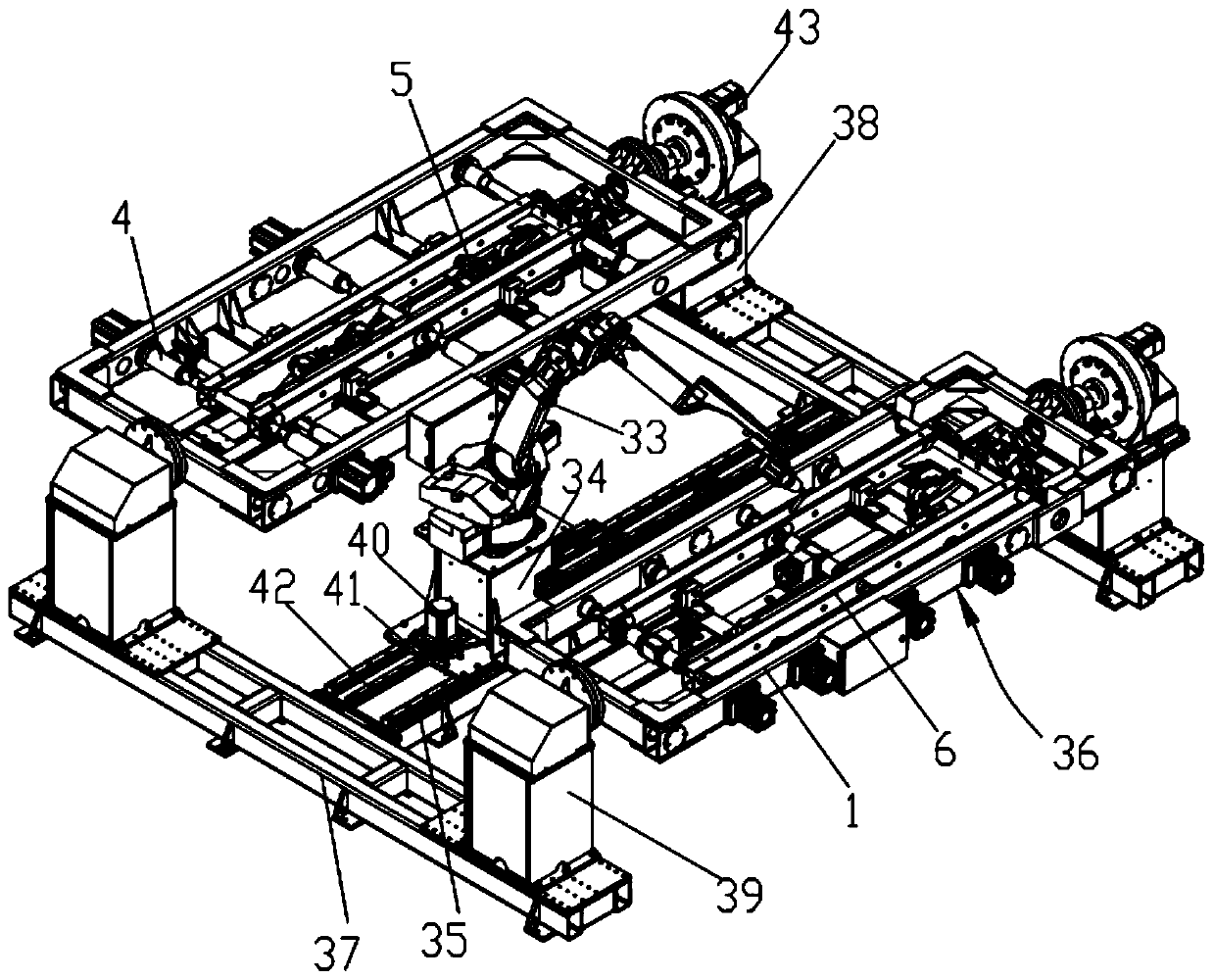

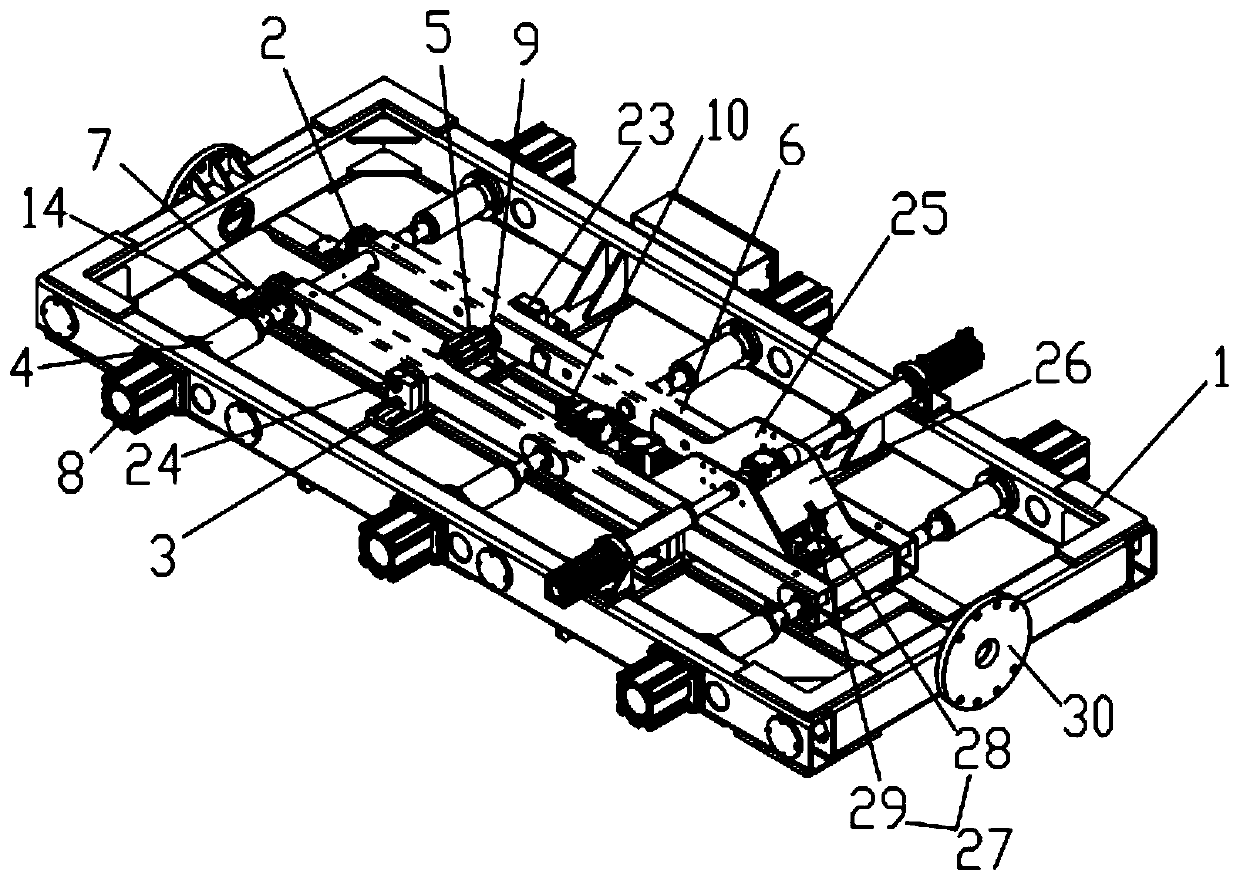

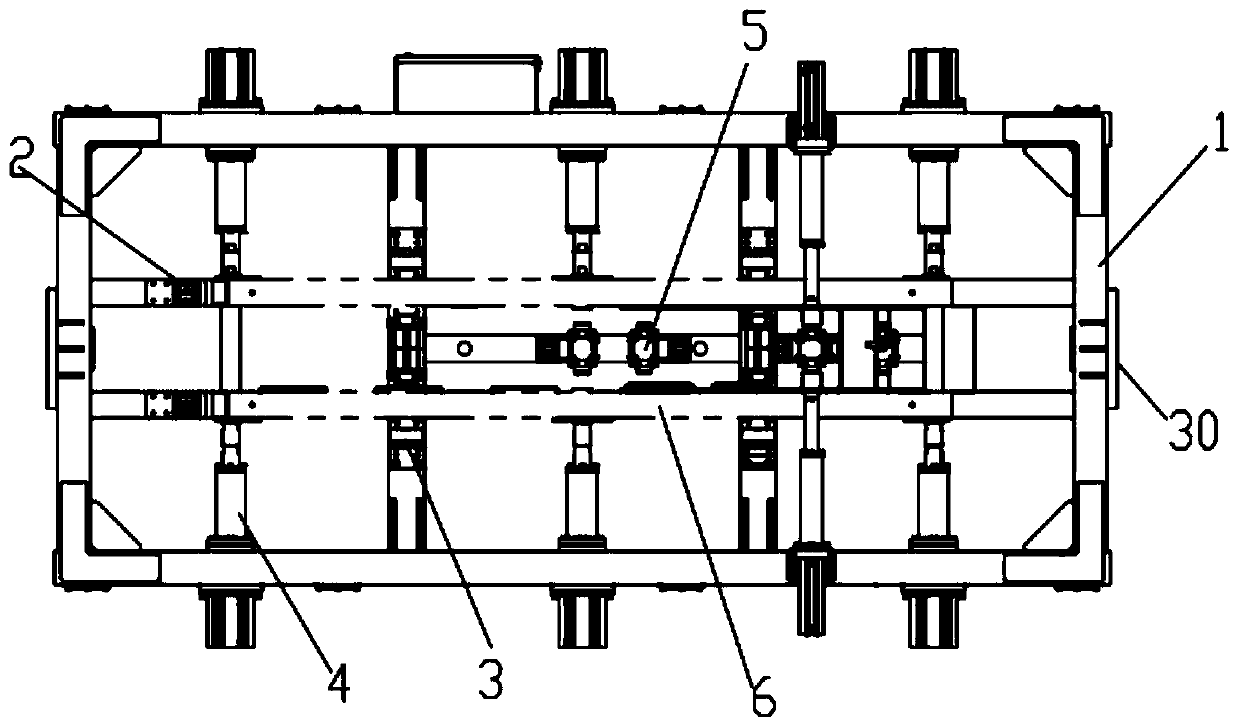

[0029] Such as Figure 1-7 As shown, the present invention discloses a scissor arm flexible welding workstation, which includes a welding manipulator 33, a manipulator mounting seat 34, a walking guide rail 35 and a positioner, and the welding manipulator 33 includes a robot body, a welding power supply, a wire feeder, and a cleaning gun System etc., are installed on the manipulator mounting base 34, and the manipulator mounting base 34 is slidingly installed on the walking guide rail 35, and positioner is installed on the both sides of the manipulator mounting base 34, and the scissor arm clamp 36 is installed on the manipulator mounting base 34 rotation. The scissor arm fixture 36 on one side of the manipulator mounting base 35 is a scissor arm we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com