Novel automatic ore-feeding regulating device for ore separating box

A technology for adjusting devices and mine separation boxes, applied in the direction of solid separation, etc., can solve the problems of high labor intensity, uneven separation of mines, low efficiency, etc., and achieve the effects of high labor efficiency, prevention of pulp wear, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

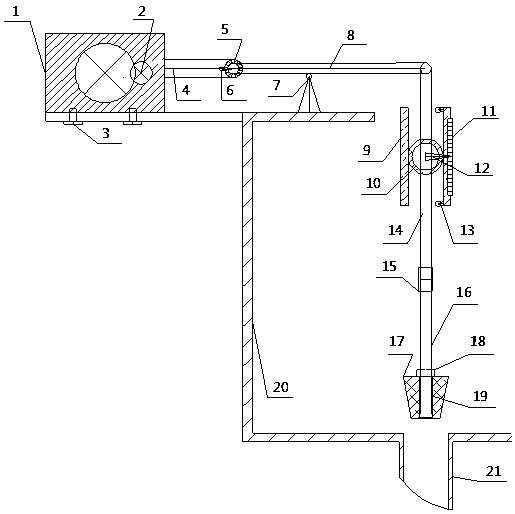

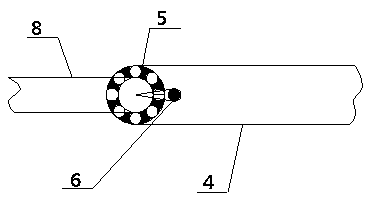

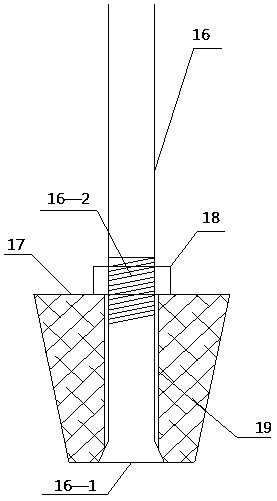

[0021] Example 1: see Figure 1-Figure 3 , a new type of automatic ore feeding adjustment device for a mine separation box, the adjustment device includes a mine separation box body 20, a manual adjustment handle 2, an electric actuator 1, an installation platform 3, a first transmission assembly and a second transmission assembly, wherein The electric actuator 1 is installed on the outrigger of the sub-mine box through the installation platform and the fixing bolt 3, which is convenient for installation and fixing, and at the same time prevents the influence of the slurry splash on the electric actuator 1 during the production process. The manual fine-tuning handle 2 is arranged on the electric actuator 1, and the electric actuator drives the second transmission assembly to move up and down through the first transmission assembly. 6 and the execution link 8, the inner ring of the sleeve ring 5 is set on the execution link 8, the sleeve buckle 6 is set on the drive link 4, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com