Microscopic light path laser coupling repeated positioning device

A repetitive positioning and laser technology, applied in microscopes, optics, optical components, etc., can solve problems such as high cost and inability to achieve, and achieve the effect of reducing design and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

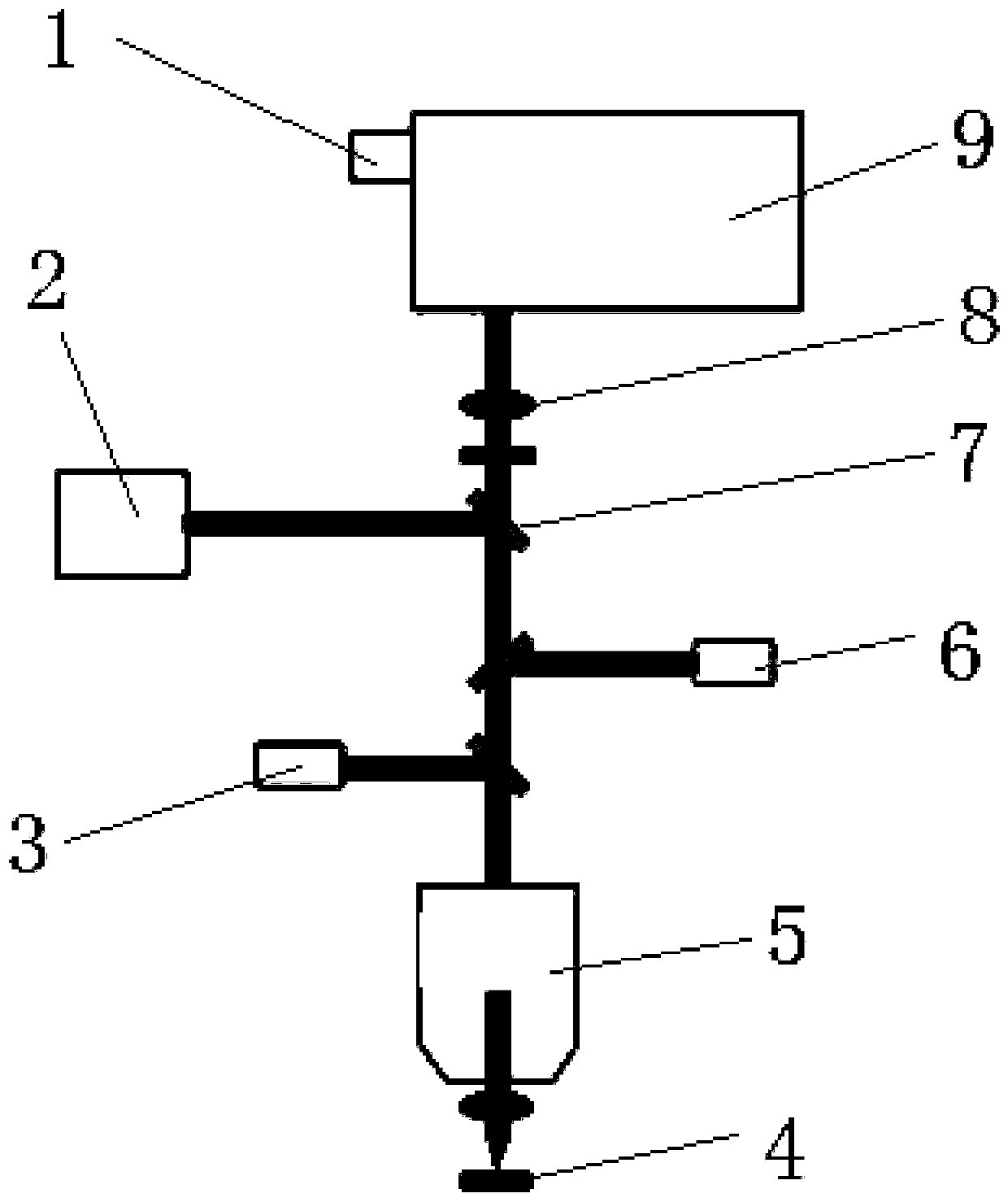

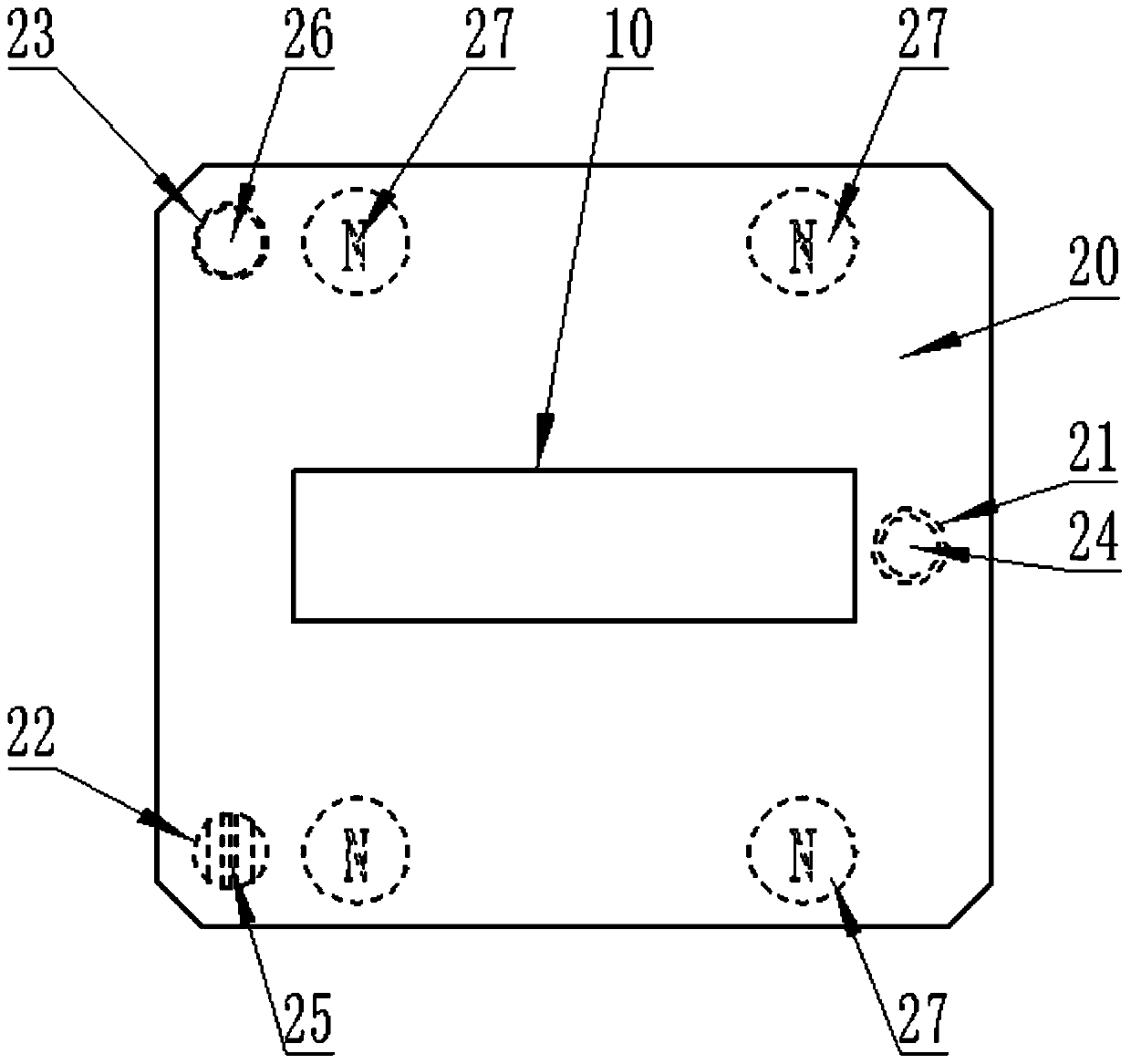

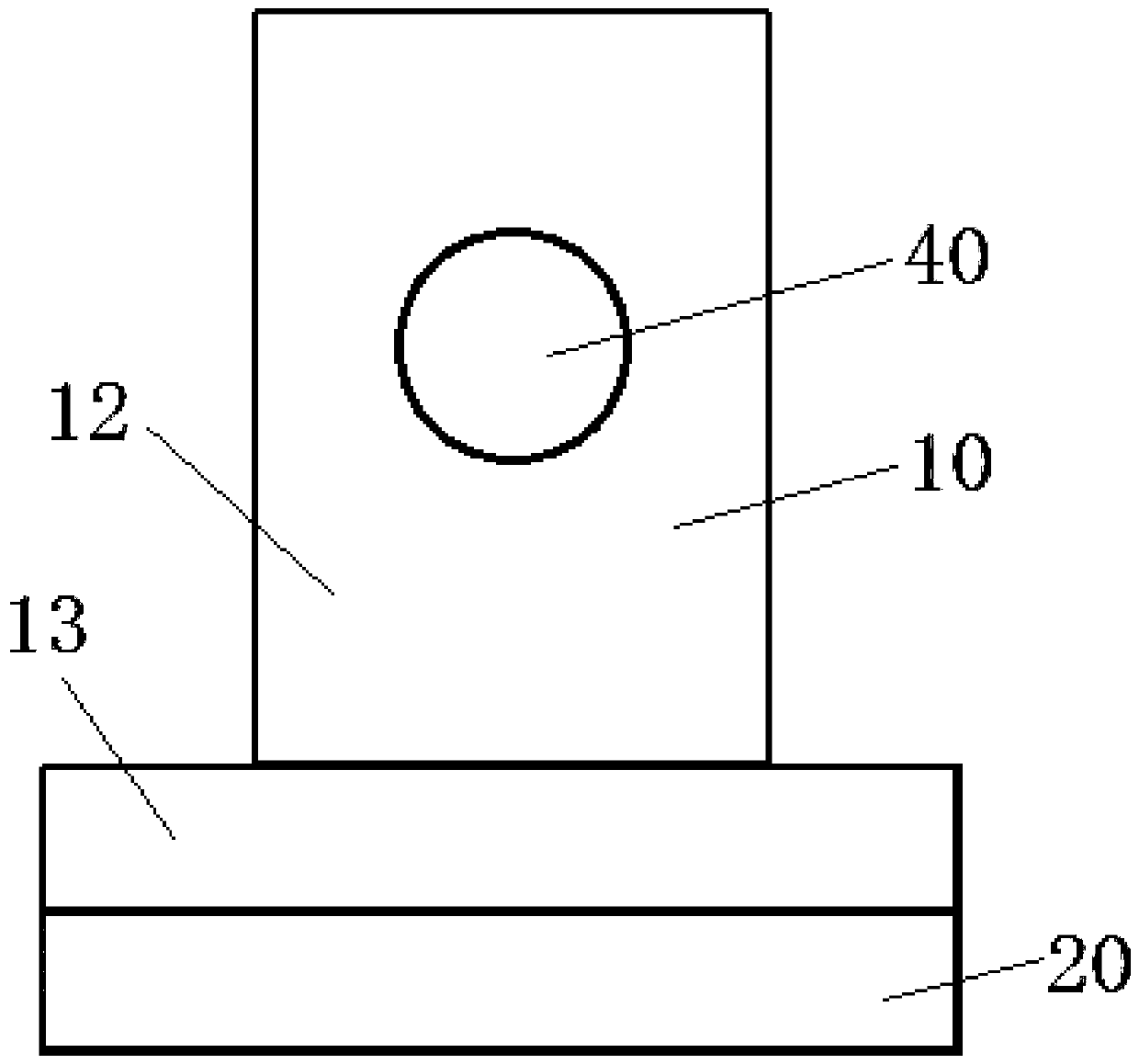

[0033] A microscopic optical path laser coupling repeat positioning device, comprising an upper lens frame 10 and a base 20 arranged up and down, three balls 30 are arranged between the upper lens frame 10 and the base 20, and three upper grooves are arranged in the upper surface of the base 20. The three upper grooves are distributed in a triangle, that is, the three upper grooves are not on the same straight line, and the three upper grooves are respectively the first upper groove 21, the second upper groove 22 and the third upper groove. Groove 23, the bottom surface of the first upper groove 21 is a tapered surface, the bottom surface of the second upper groove 22 is a V-shaped surface, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com