Front end support traverse device and traverse method for variable span double support and large displacement for trestle

A technology of traverse device and double support, used in bridge applications, bridges, movable bridges, etc., can solve the problems of requiring no less than 2.5 hours, invariable column span, restricting the progress of tunnel construction, etc., so as to shorten the short distance of trestle bridges. , the effect of solving the constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

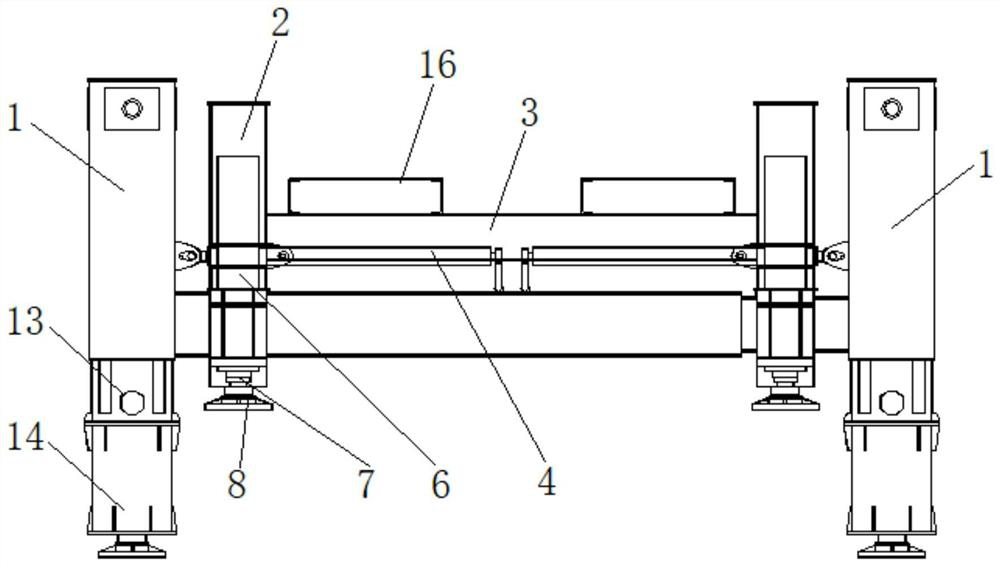

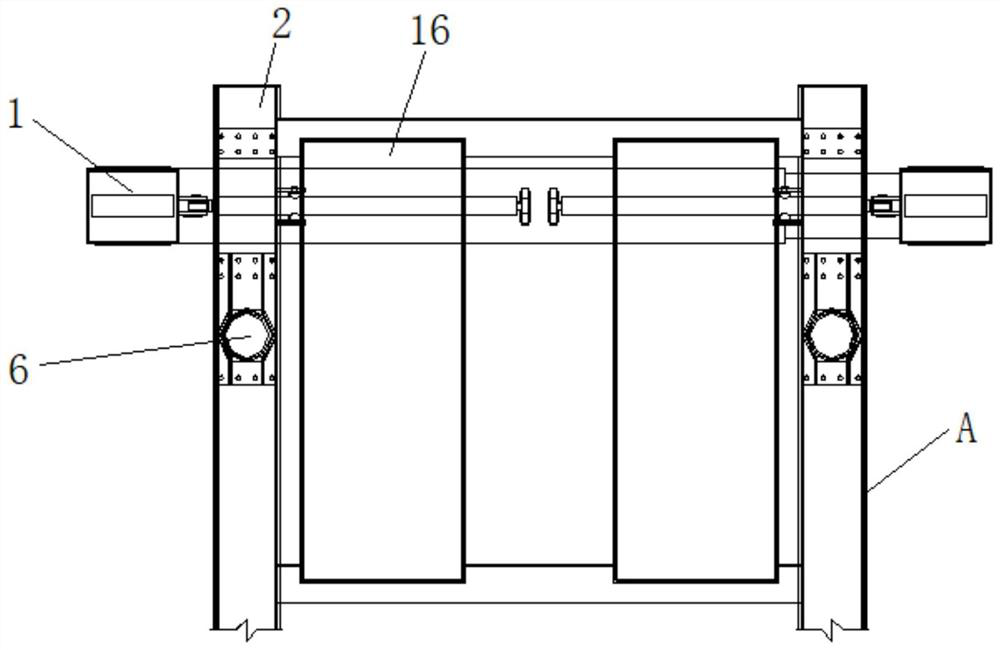

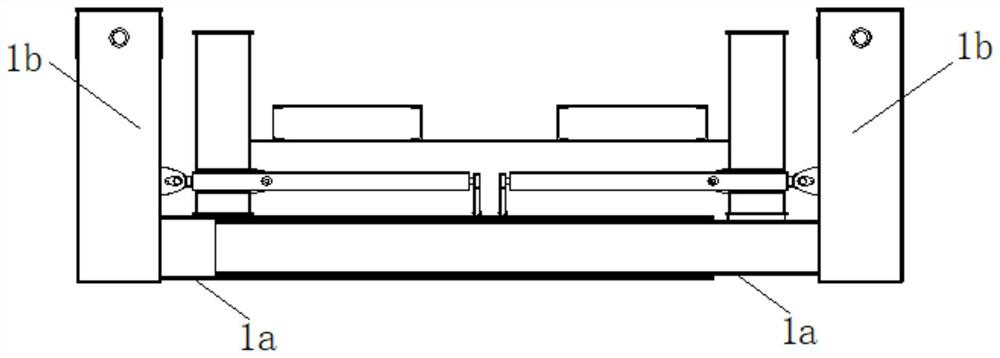

[0028] Below, the present invention will be further described through the embodiments in conjunction with the accompanying drawings, with the tunnel length direction as the front and rear directions, and the tunnel width direction as the left and right directions for description:

[0029] combine figure 1 — Figure 7 As shown, a trestle bridge uses a variable-span double-support large-displacement front-end support traverse device, which is mainly composed of a basic column 1, trestle main beam 2, corbel beam 3, traverse hydraulic cylinder 4, hoop assembly 5, and lifting hydraulic cylinder 6 , Universal ball joint 7, support foot 8, screw ejector rod 9, roller 10, roller bracket 11, cylinder barrel pin 12, column telescopic sleeve 13, fixed lengthening support leg 14, lubricating sleeve 15 forms.

[0030] The two trestle main girders 2 are symmetrically arranged left and right, and the two trestle main girders 2 are connected by corbels 3 to form an "H"-shaped middle fixing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com