Multistage rocket transportation erecting vehicle

A technology for transport vehicles and rockets, which is applied in the field of multi-stage rocket transport erectors, which can solve the problems of low operating efficiency, long assembly process, low standardization and automation, and achieve improved bending resistance, shortened assembly time, and automation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

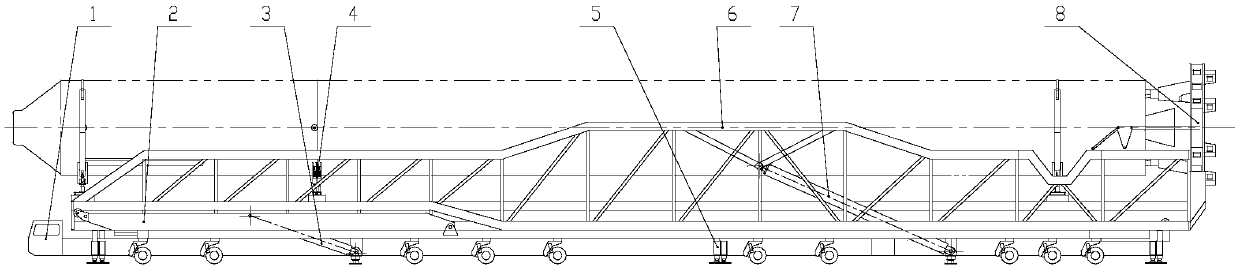

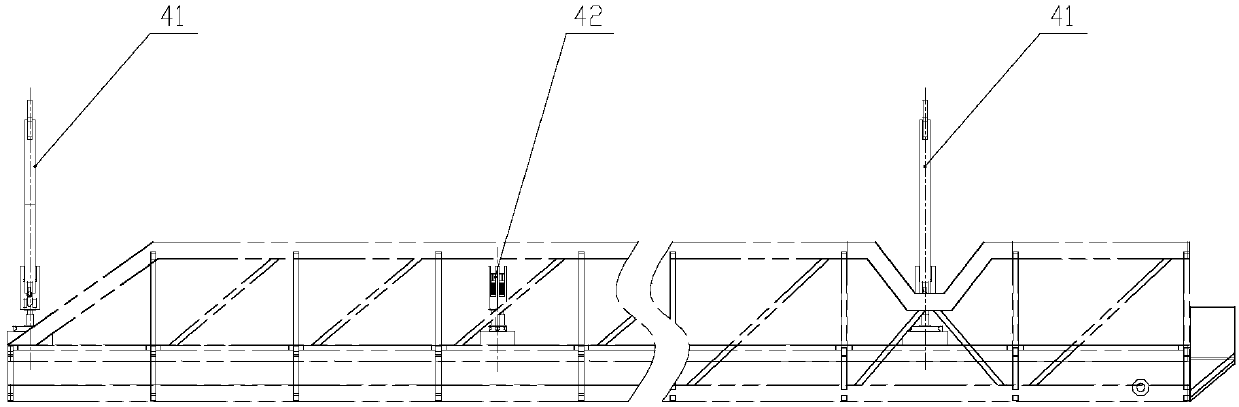

[0022] as attached figure 1 As shown, the present invention provides a multi-stage rocket transport erecting vehicle, including a transport vehicle 1, an auxiliary support arm 2, an auxiliary support cylinder 3, a support adjustment system 4, hydraulic legs 5, a vertical arm assembly 6, a main Erect oil cylinder 7 and support seat 8.

[0023] The transport vehicle includes a driver's cab, a driving system, a power system and a vehicle frame structure; the transport vehicle is the main carrier of the remaining components of the present invention, and is also the main realization component of rocket transportation and transfer.

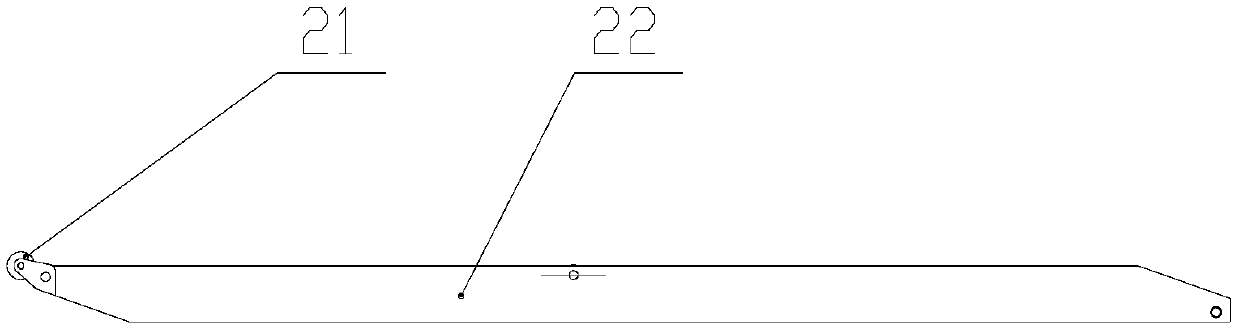

[0024] The root of the auxiliary support arm 2 is hinged on the frame structure of the transport vehicle 1, the middle part of the auxiliary support arm 2 is hinged with the auxiliary support cylinder 3, and the other end of the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com