Bogie assembling and completing technology and swing bolster side frame assembling machine

A bogie and assembly machine technology, applied in assembly machines, metal processing, manufacturing tools, etc., can solve the problems of large production line occupation area, high labor intensity, low cutting production efficiency, etc., so as to utilize the ground operation space and save operation time. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

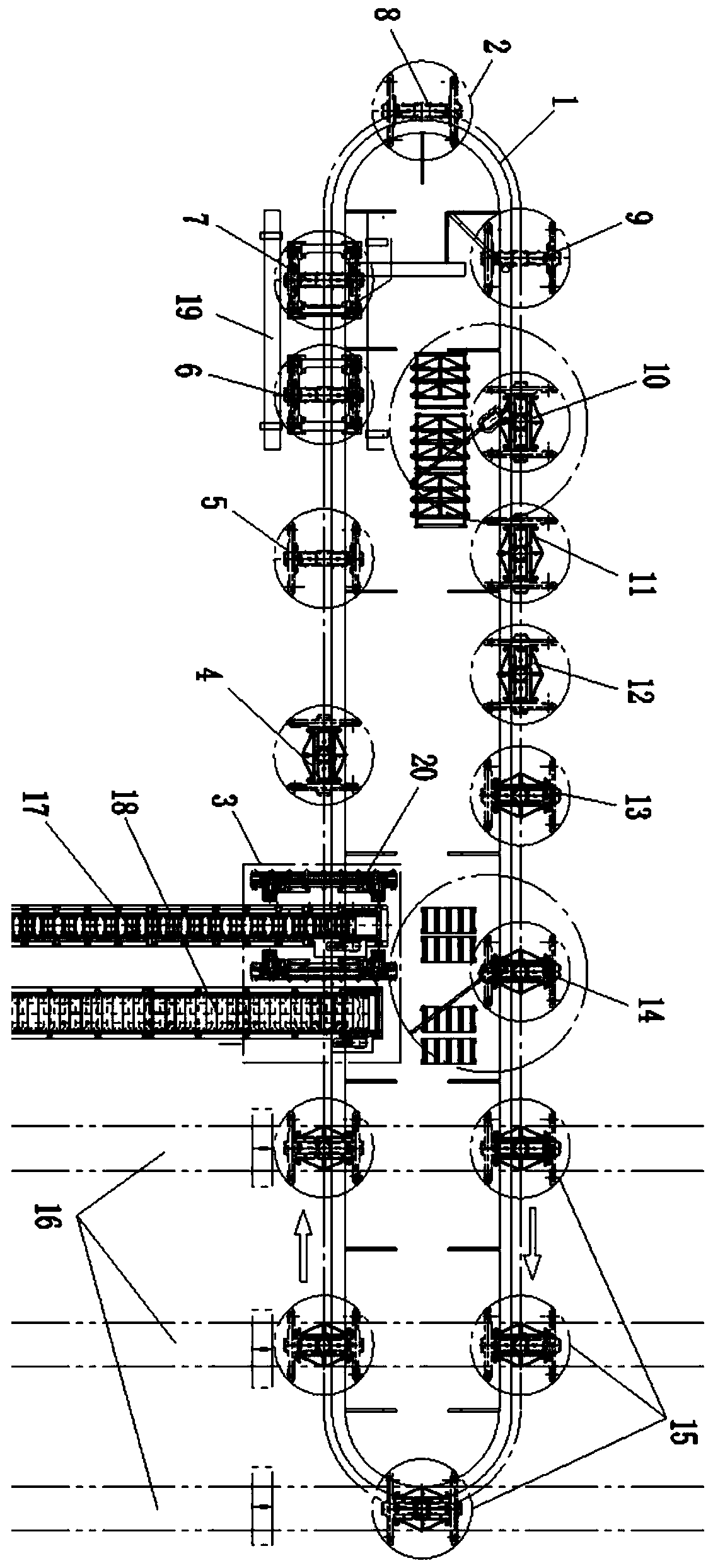

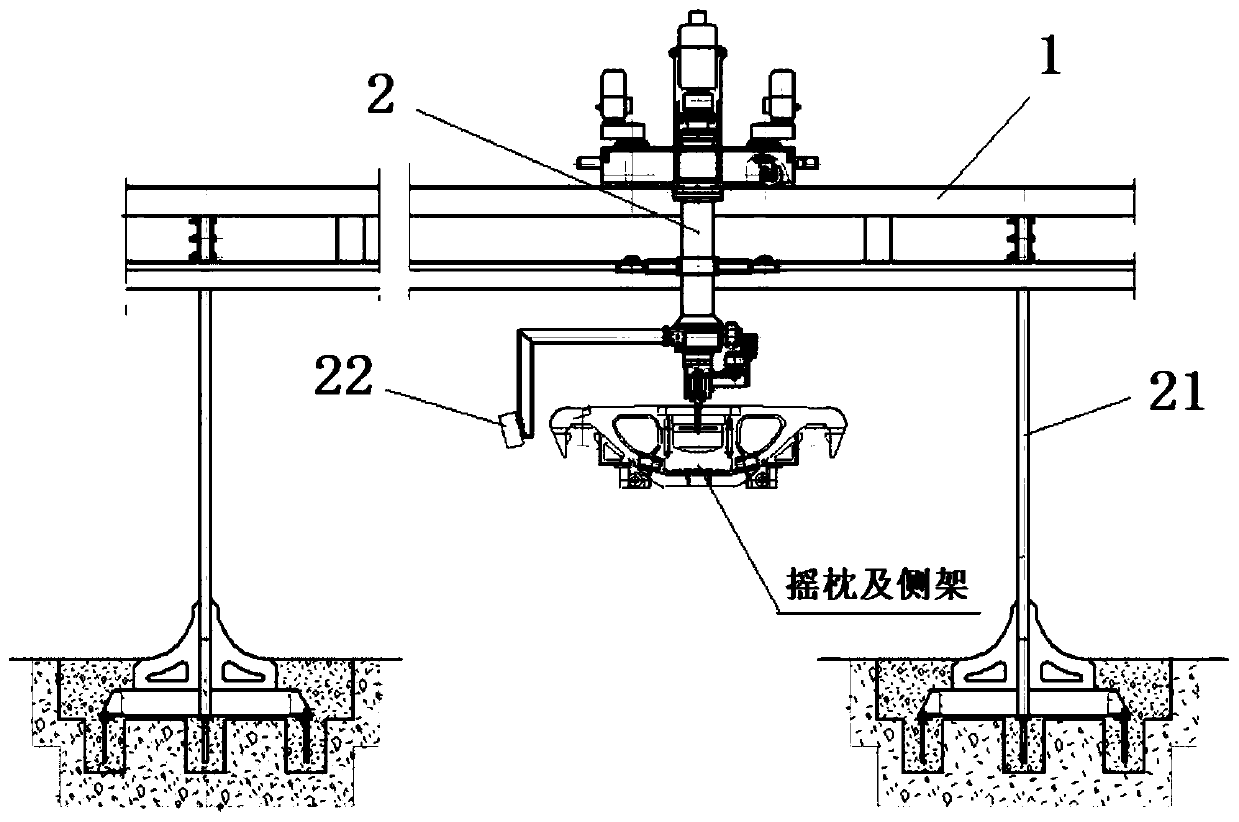

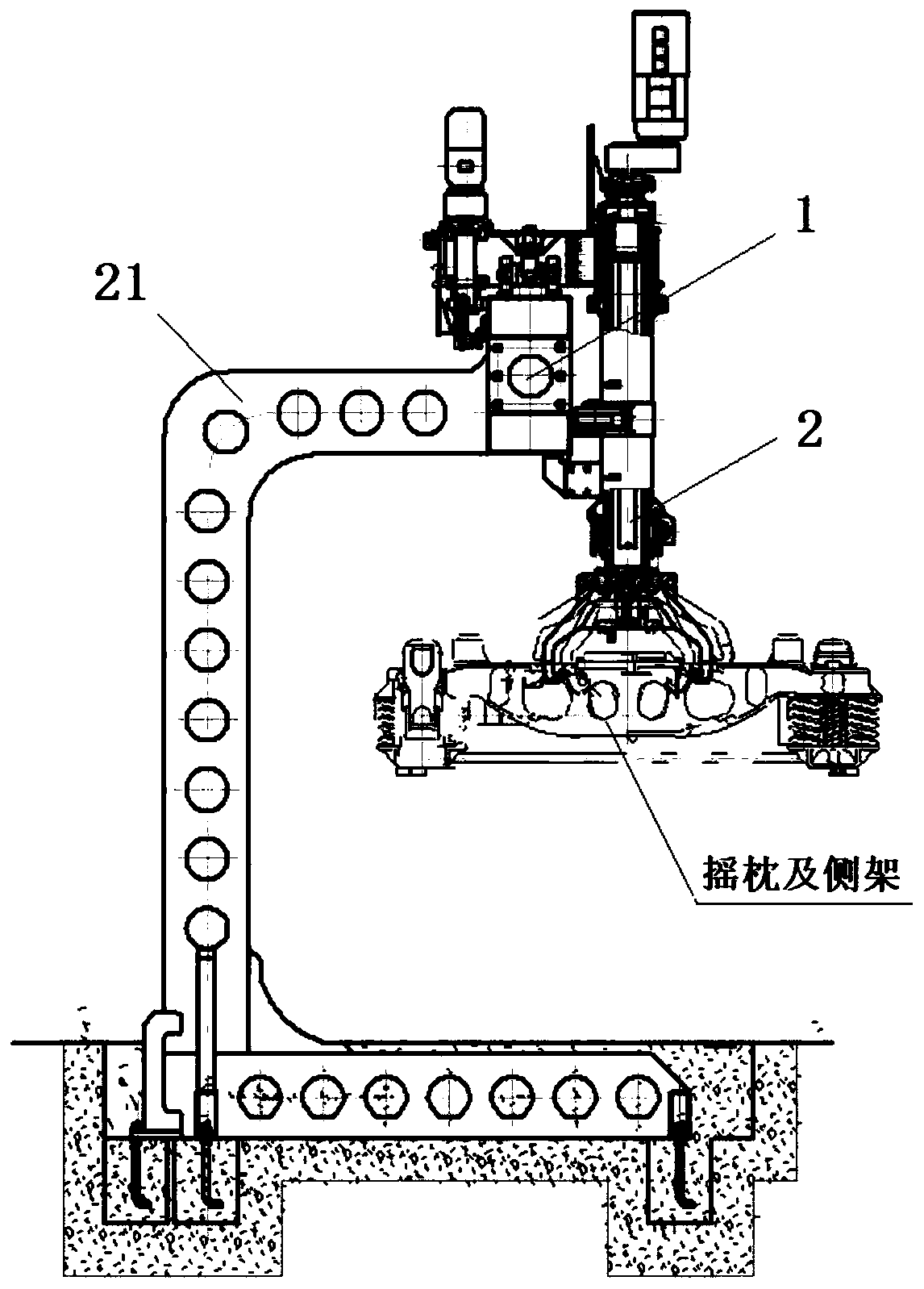

[0031] Examples of the present invention: see Figure 1~3 as well as Figure 7 In the bogie assembly and completion process of the present invention, the semi-gantry support frame 21 is used to support the oval track 1 in the assembly workshop, and two or more are installed on the oval track 1 and can follow the oval track 1. The walking suspension manipulator 2, and then arrange the bolster and side frame assembly station 3, the spring and diagonal wedge assembly station 4, the cross bar assembly station 5, and the cross bar along the elliptical track 1 in sequence under the elliptical track 1. Rod bolt fastening station 6, positive detection station 7, suspension station 8, side bearing installation station 9, brake beam assembly station 10, cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com