Range hood with noise reduction structure

A range hood and noise reduction technology, applied in the field of kitchen equipment, can solve the problems of difficult cleaning of sound-absorbing cotton oil, affect user experience, affect noise reduction effect, etc., and achieve the effect of easy cleaning, improving user experience, and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

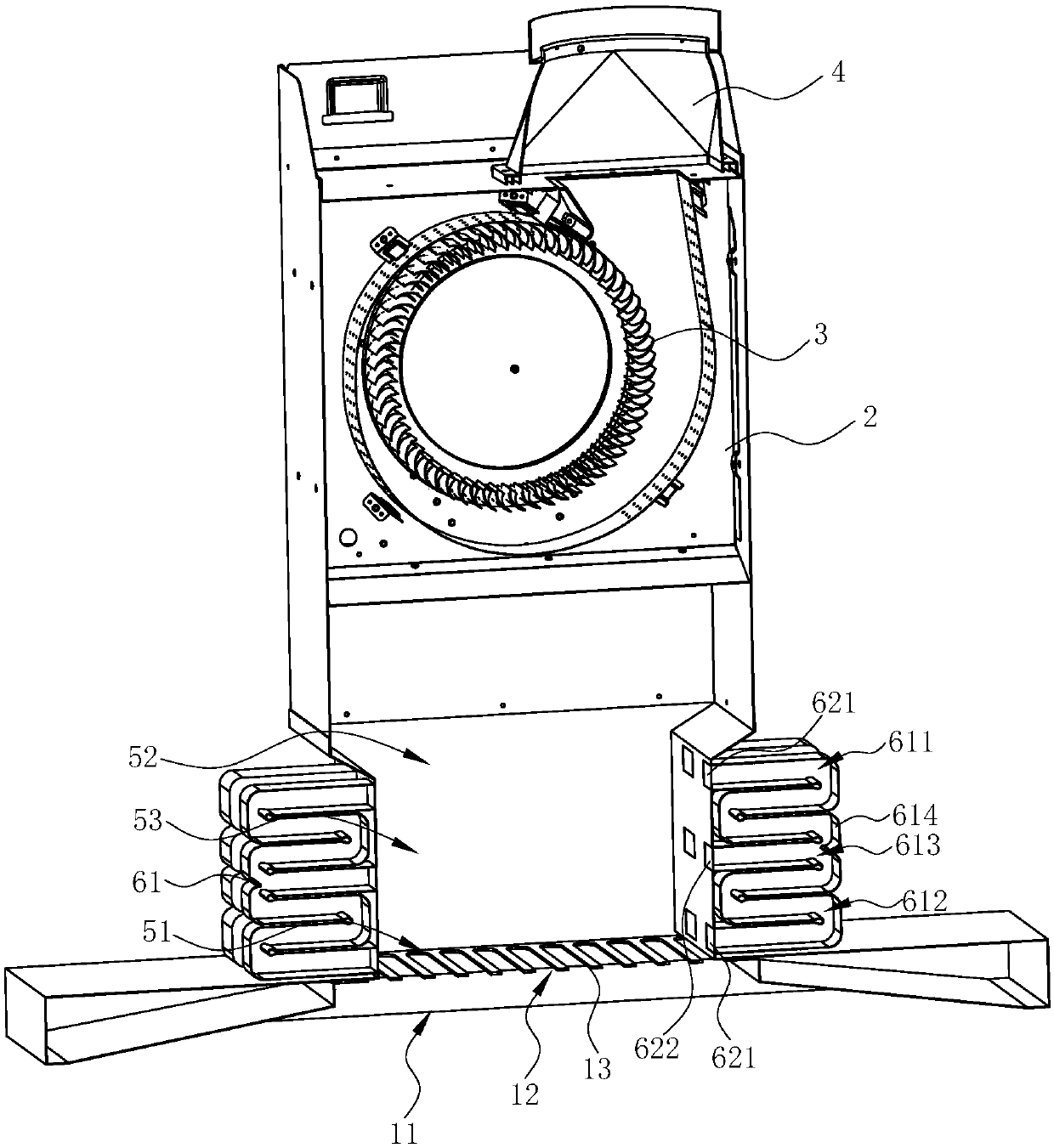

[0021] see Figure 1 ~ Figure 3 , a range hood with a noise reduction structure, comprising a smoke collecting hood 1, a chassis 2 located above the fume collecting hood 1, a fan 3 arranged in the chassis 2, and an air outlet hood 4 is arranged at the air outlet of the fan 3.

[0022] An upwardly recessed smoke collection cavity 11 is formed in the smoke collection hood 1 , and an air inlet 12 is formed on the top of the smoke collection hood 1 for oil fumes to enter the cabinet 2 from the smoke collection chamber 11 , and a filter screen 13 is arranged at the air inlet 12 .

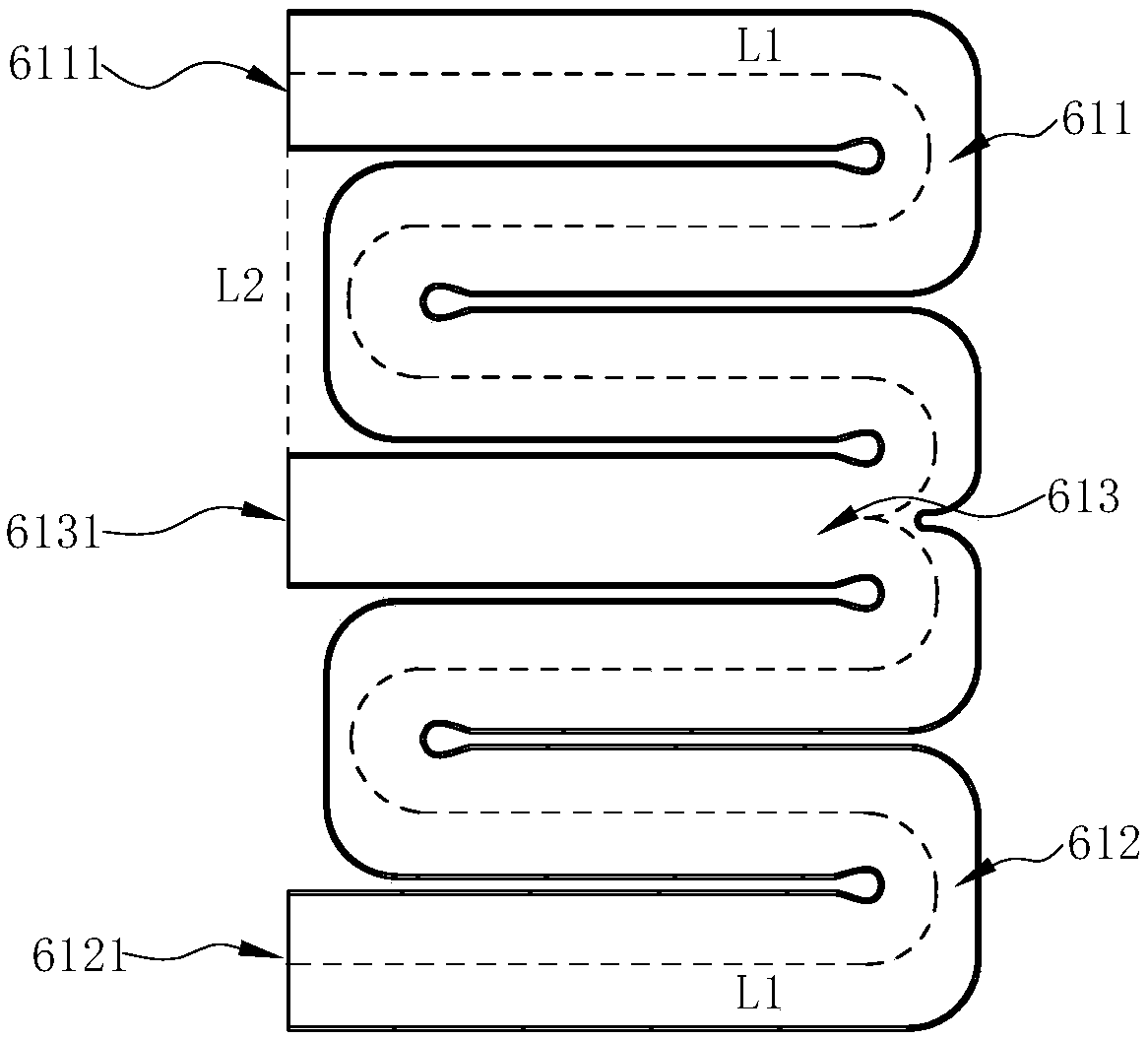

[0023] An air inlet hood 5 is arranged between the top of the smoke collecting hood 1 and the cabinet 2, the bottom of the air inlet hood 5 is connected with the top of the smoke collecting hood 1, and the bottom of the air inlet hood 5 is provided with a first opening 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com