Mixing flame stabilizing device

A flame stabilization device and mixer technology, which is applied in jet propulsion devices, rocket engine devices, combustion methods, etc., can solve the problems of limited penetrating ability of combustible gas, difficulty in efficient and uniform mixing, etc. Penetration ability, the effect of improving flame stabilization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

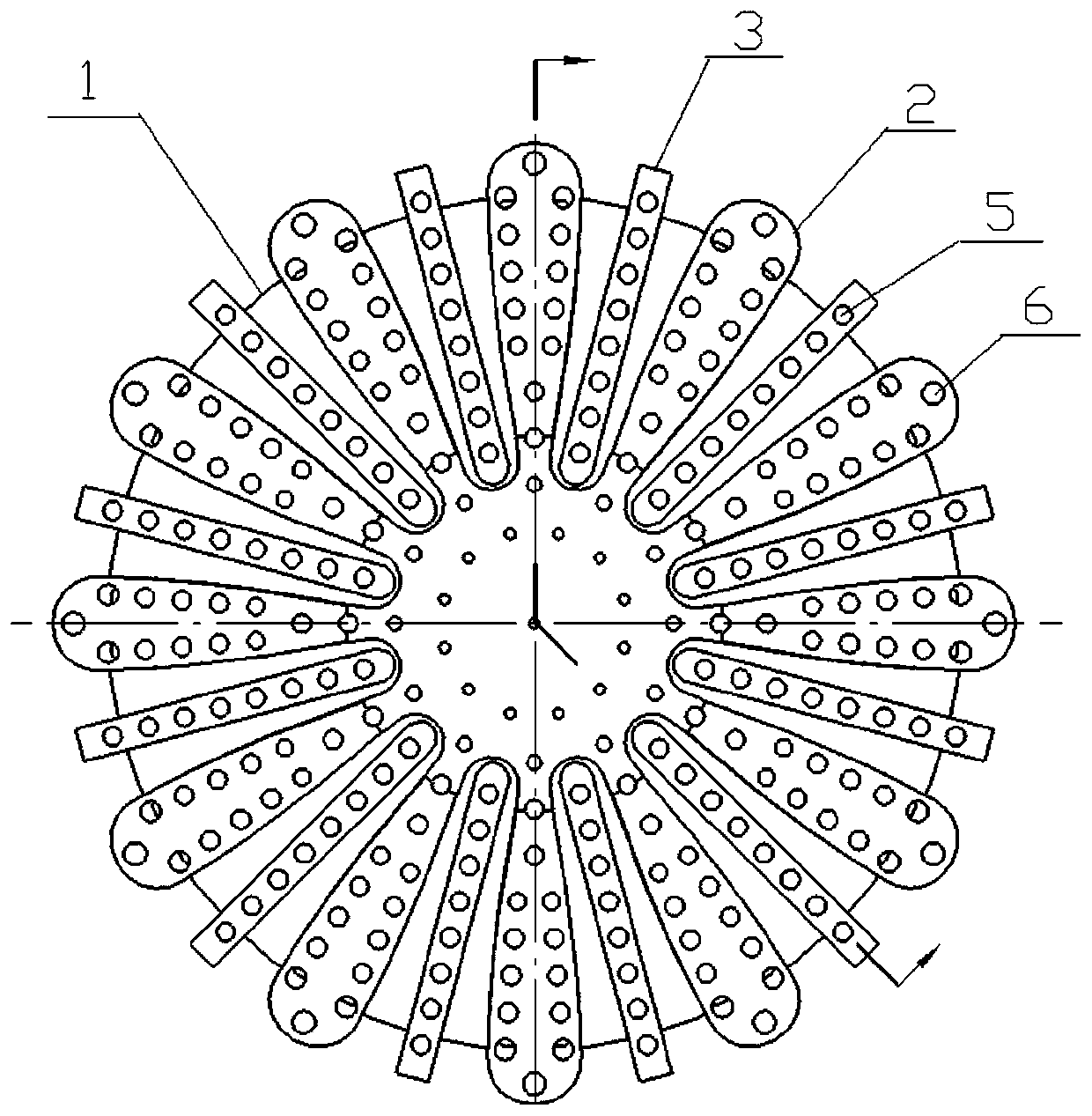

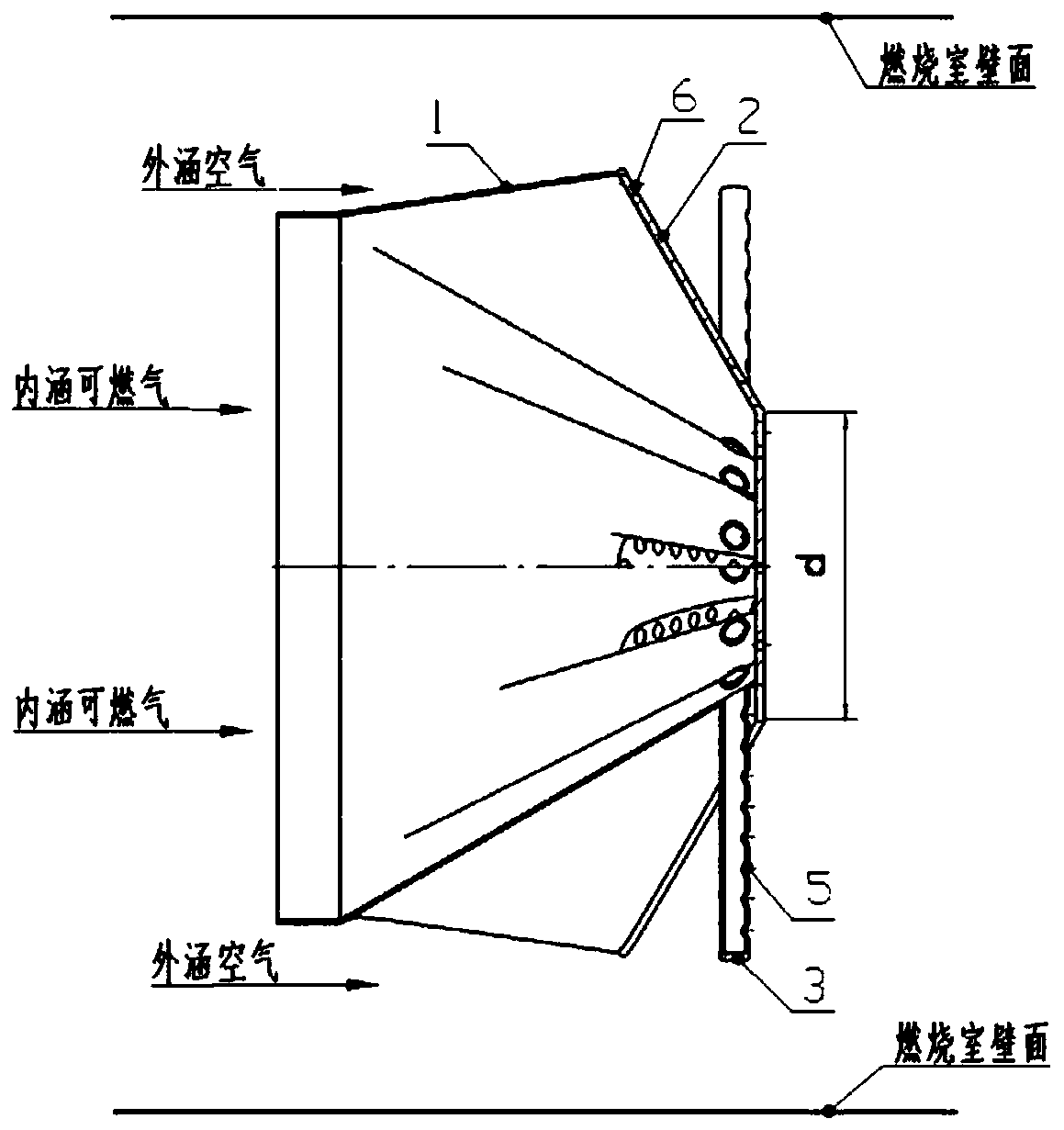

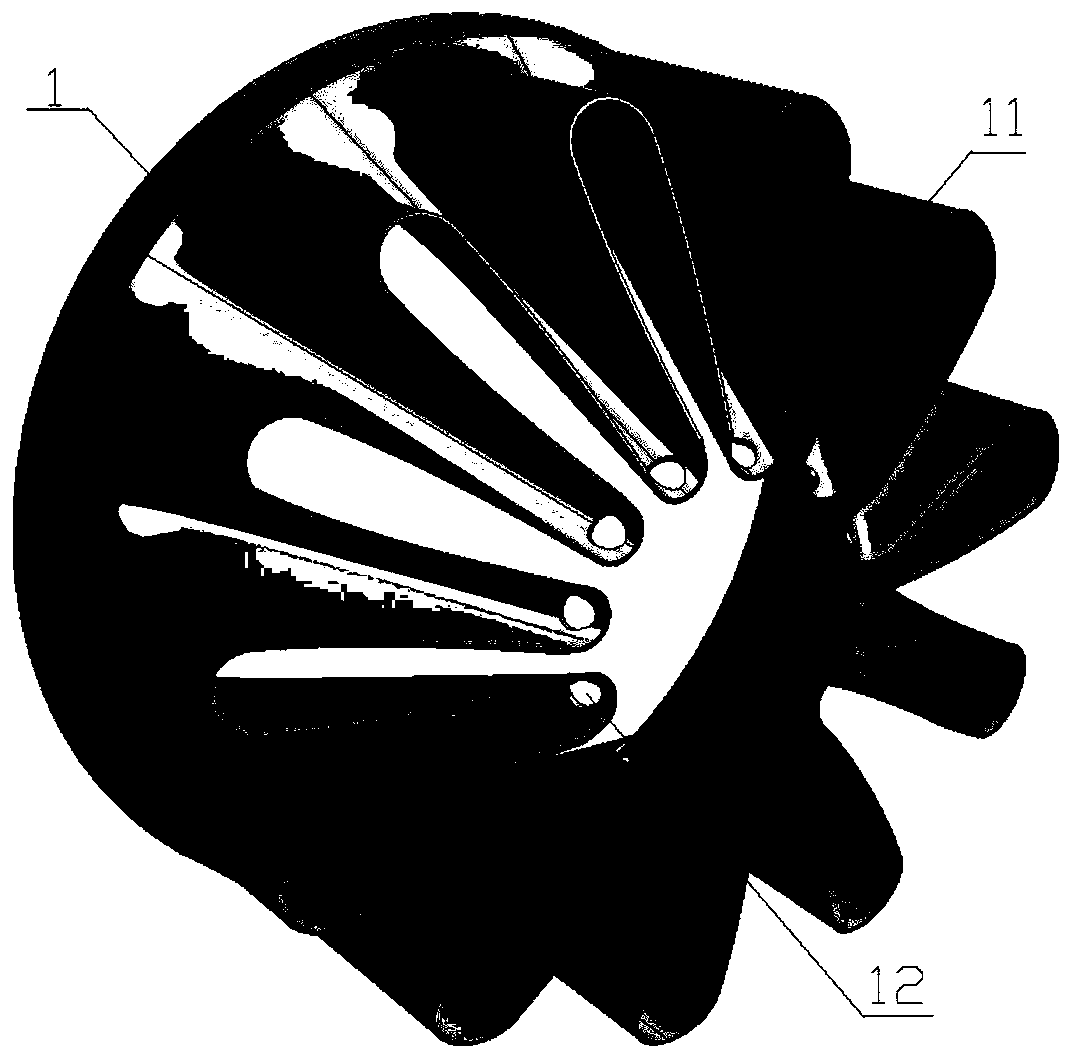

[0025] The mixing of the inner and outer airflows at the inlet of the combustor of the combined power engine usually adopts a lobe mixer, and the viscous shear stress of the boundary layer of the two airflows at the trailing edge of the lobe is used to strengthen the mixing. However, the penetration ability of combustible gas in the gaseous environment is limited, and it is difficult to achieve efficient and uniform mixing of the two airflows in a short distance only by relying on the viscous shear of the velocity difference between the inner and outer airflows. Therefore, a more efficient enhanced mixing mechanism must be adopted to improve the spatial dispersion characteristics of the two airflows, shorten the mixing distance, enhance the mixing and mixing of air and combustible gas under complex incoming flow conditions, improve combustion efficiency, and improve the overall performance of the engine. Performance, the improvement that the present invention makes just for thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com