High-stress roadway combined ring beam supporting structure and construction method thereof

A support structure and combined ring technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems that affect the safety of coal mine production, bulging of the bottom plate and two sides, and difficult support stability, so as to avoid the short board effect , Improve the strength and improve the overall bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

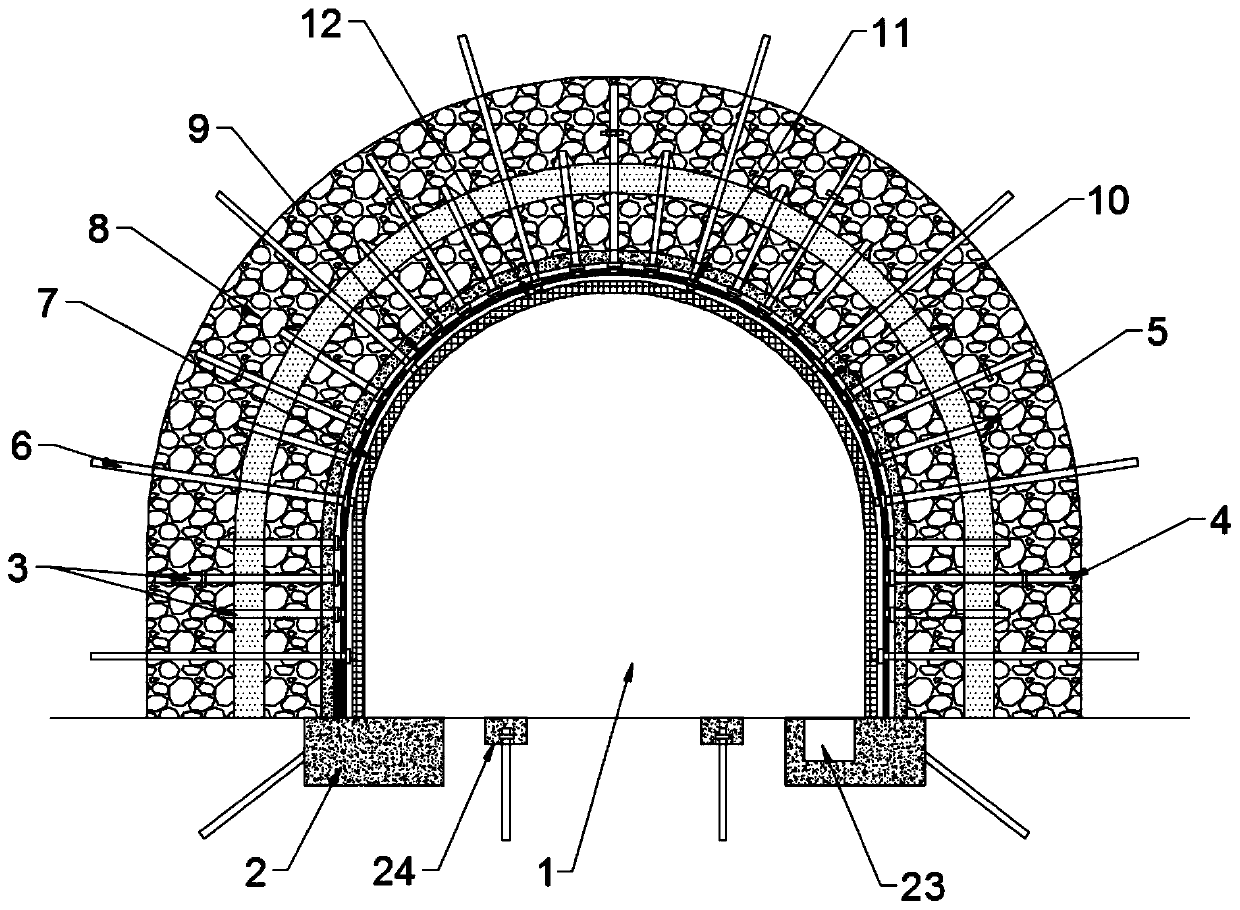

[0034] The technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

[0035] See Figure 1 ~ Figure 3 , A high-stress roadway composite ring body beam support structure, comprising a roadway 1 and a support ring body 12. The roadway 1 is composed of an upper semicircular part and a semicircular part of the lower part of the two sides connected as a whole rectangular side wall , A homogeneous and homogeneous support ring body 12 is constructed around the roadway 1 to implement active support for the roadway 1. The support ring body 12 is used to support the surrounding rock 8 outside the roadway 1, and to support the surrounding rock 8. For circle 12, whether the support of roadway 1 is damaged or not does not depend on the strongest part of the support, but on the weakest part of the support.

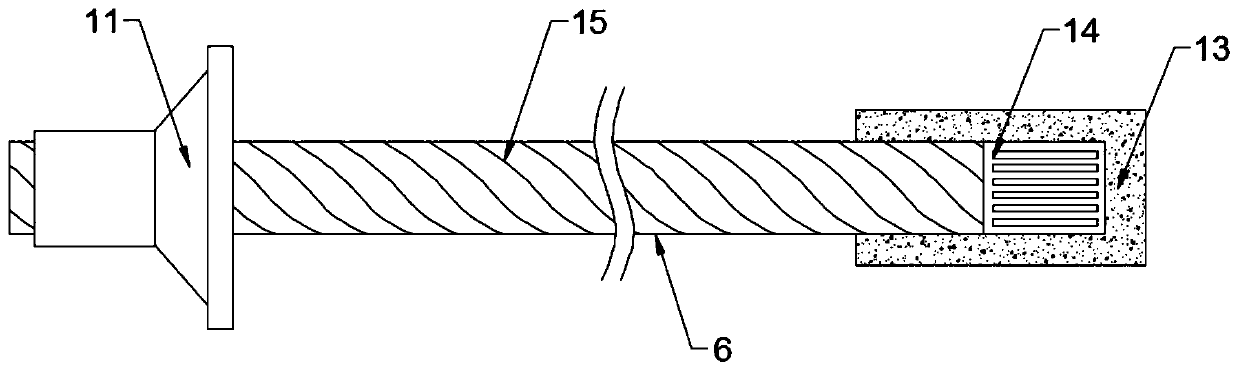

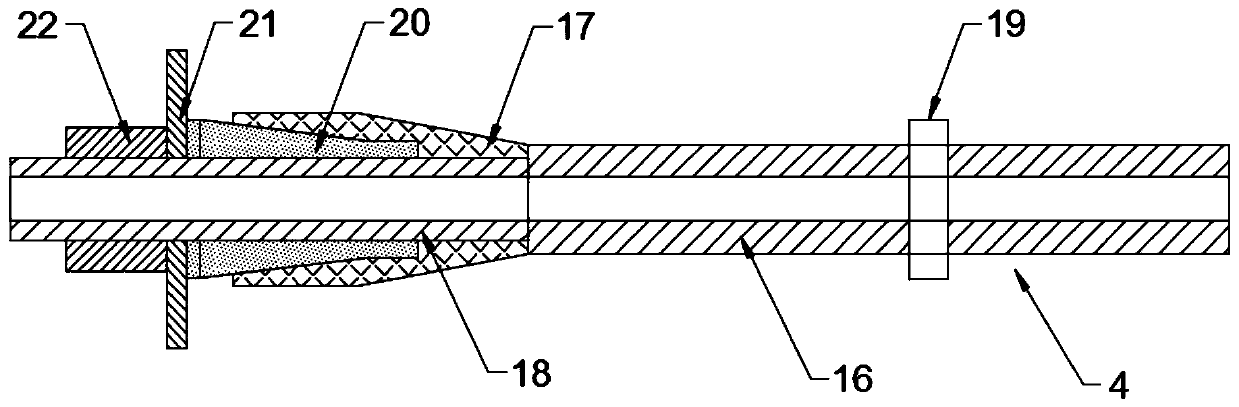

[0036] The supporting ring body 12 includes a grouting bolt 3, an anti-pull bolt 6, a U-shaped steel bracket 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com