Preparation method of rhodium complex

A rhodium complex and reactor technology, applied in the directions of rhodium organic compounds, chemical instruments and methods, platinum group organic compounds, etc., can solve the problems of high production cost, unfavorable environment and safety, high rhodium price, etc. The effect of production time, increased utilization, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

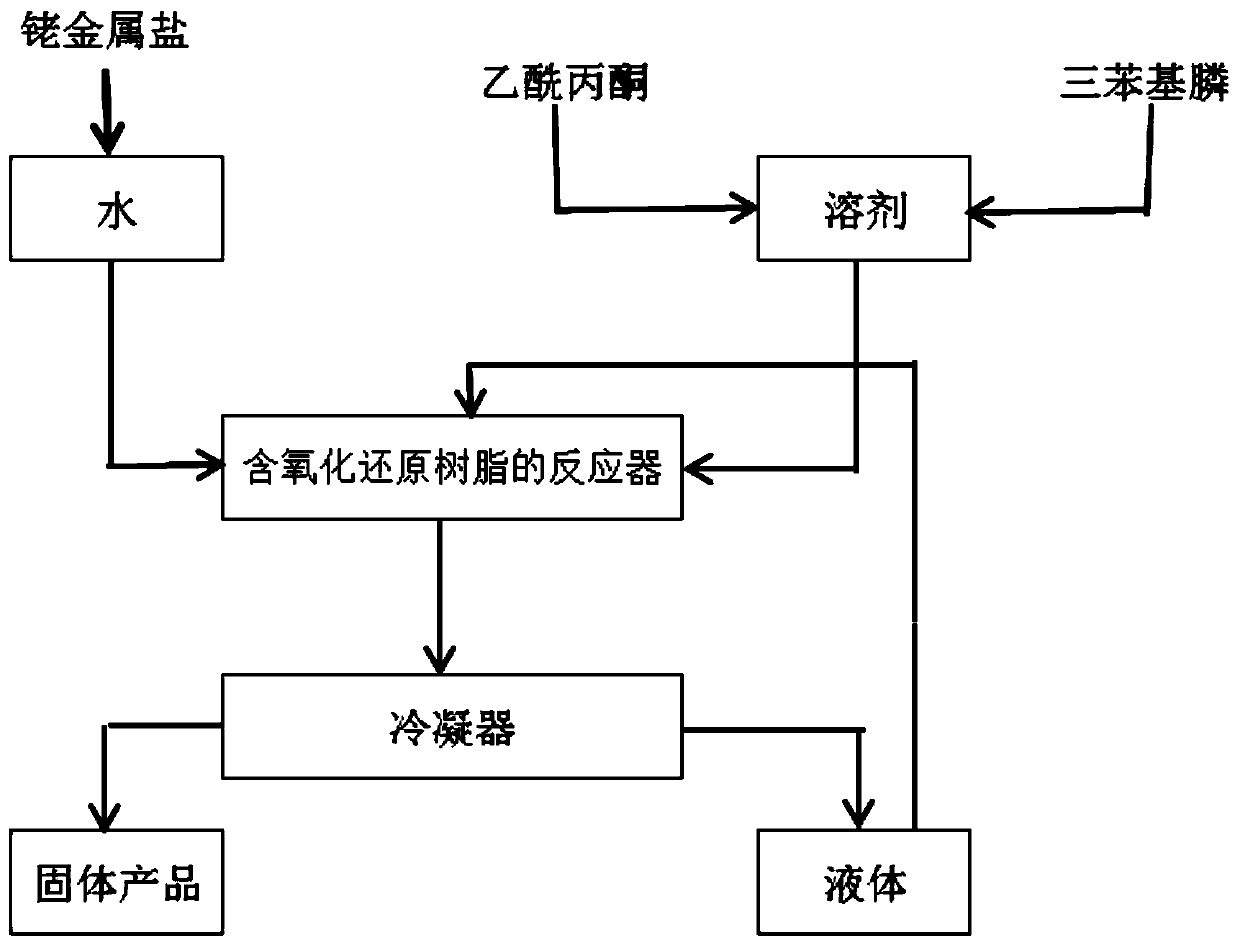

Image

Examples

Embodiment 1

[0024] Dissolve 1 mole of rhodium chloride in pure water; dissolve 1.05 moles of acetylacetone and 1.05 moles of triphenylphosphine in N,N-dimethylformamide and toluene (1:1); use hydroxymethylpolyphenyl Ethylene (CAS 66072-40-0) was filled into the two-stage 5L reactor; at 120°C, the rhodium trichloride solution and the acetylacetonate triphenylphosphine solution were added according to the reaction ratio and passed through the two-stage reactor at 5ml / min; The product uses condensed water for condensation and crystallization, and the liquid is transferred to the previous step for the next reaction. The obtained product was analyzed by an elemental analyzer as C 58.6%, H 4.5%, Rh content 20.82%, product purity over 99%, and primary yield 89%.

Embodiment 2

[0026] 1 mole of rhodium chloride was dissolved in pure water; 1.05 moles of acetylacetone and 1.05 moles of triphenylphosphine were dissolved in the reaction solution of Example 1; p-hydroxystyrene was used to fill the two-stage 5L reactor; at 120 ℃, add rhodium trichloride solution and triphenylphosphine acetylacetonate solution according to the reaction ratio and pass through the two-stage reactor at 5ml / min; the product uses condensed water for condensation crystallization, and the liquid is transferred to the previous step for the next reaction. The obtained product is analyzed by an elemental analyzer as C58.6%; H4.5%, Rh content is 20.82%, product purity is more than 99%, and primary yield is 90%.

Embodiment 3

[0028] Dissolve 1 mole of rhodium chloride in pure water; dissolve 1.05 moles of acetylacetone and 1.05 moles of triphenylphosphine in N,N-dimethylformamide and toluene (1:1); use hydroxymethylpolyphenyl Ethylene (CAS 66072-40-0) is filled into the two-stage 50L reactor; at 120°C, the rhodium trichloride solution and the triphenylphosphine acetylacetonate solution are added in proportion and passed through the two-stage reactor at 150ml / min; the product Condensed water is used for condensation crystallization, and the liquid is transferred to the previous step for the next reaction. The obtained product was analyzed by an elemental analyzer as C 58.6%, H 4.5%, Rh content 20.82%, product purity over 99%, and yield 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com