Prediction method for machine fault

A machine failure and prediction method technology, applied in the direction of instruments, computer parts, design optimization/simulation, etc., can solve problems such as failure early warning of equipment that cannot generate electricity, avoid economic losses and casualties, and improve prediction accuracy and robustness , the effect of improving safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

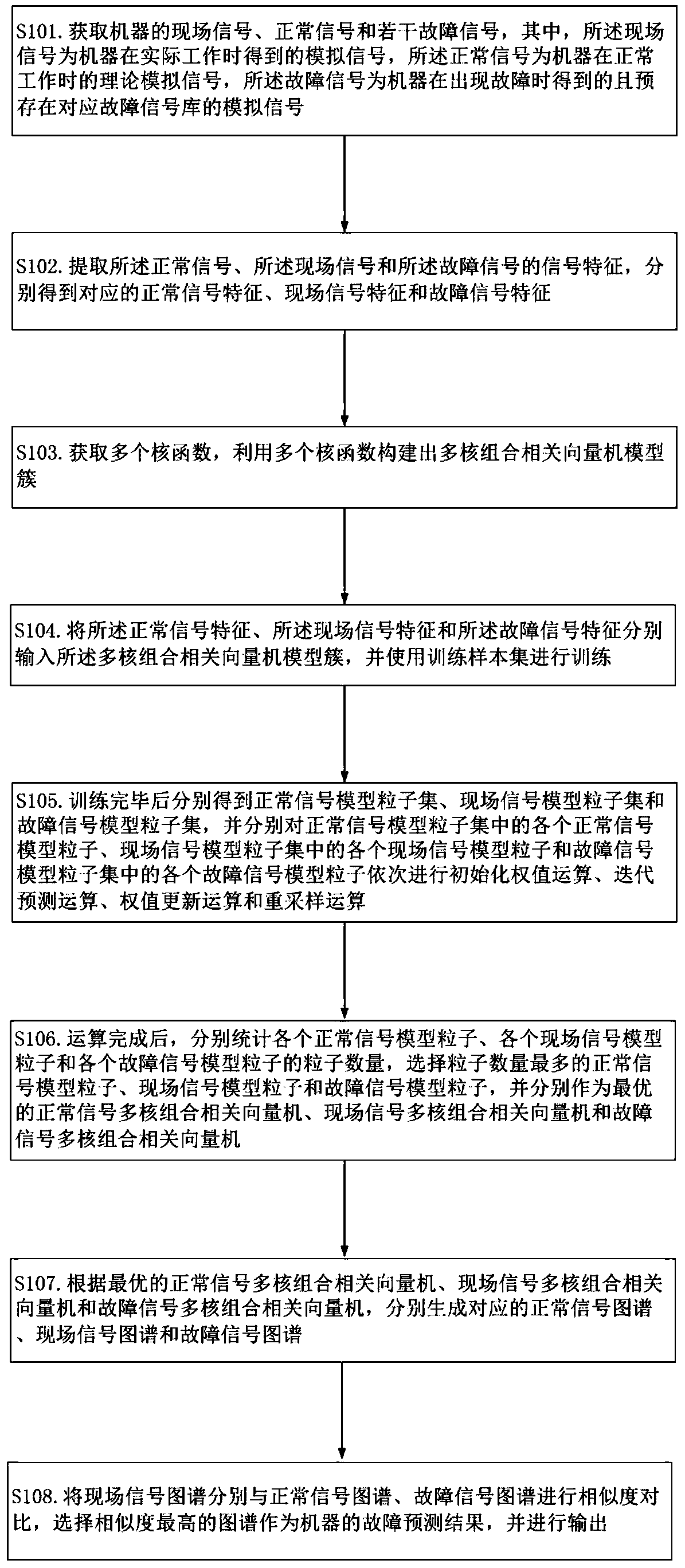

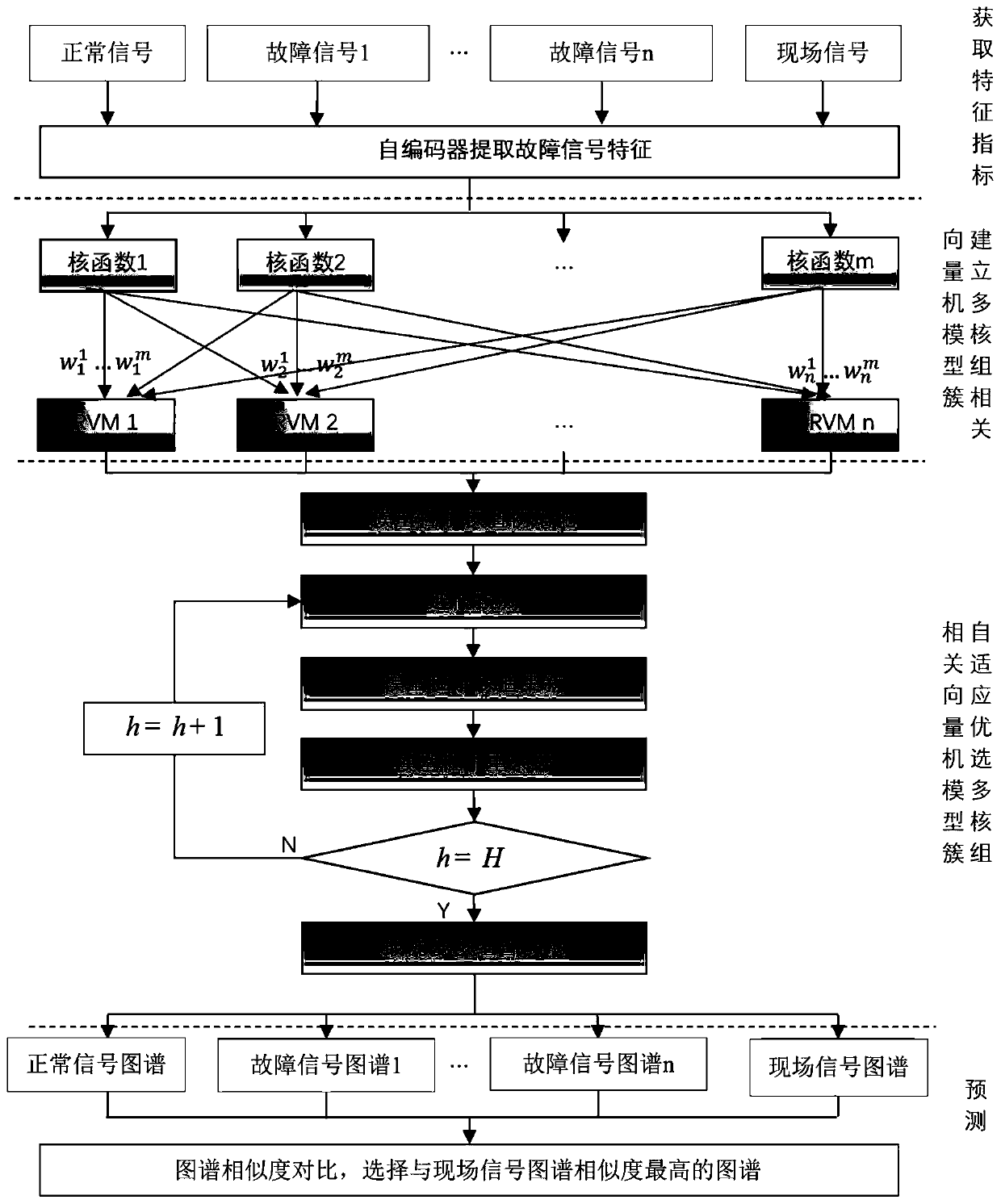

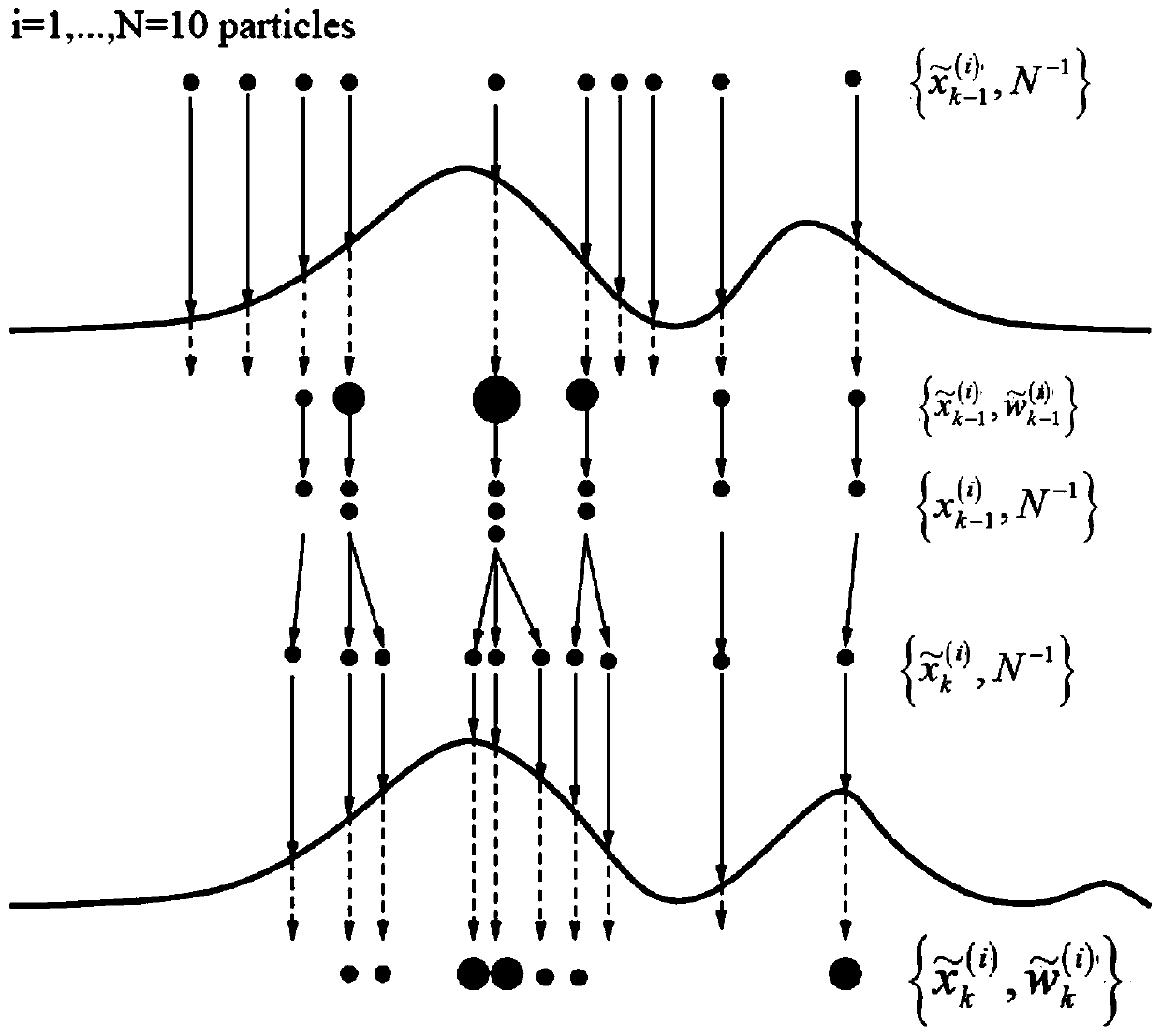

[0058] like Figures 1 to 3 As shown, the prediction method of machine failure provided in this embodiment includes the following steps:

[0059] S101. Obtain the on-site signal, normal signal and several fault signals of the machine, wherein the on-site signal is an analog signal obtained when the machine is actually working, the normal signal is a theoretical analog signal when the machine is working normally, and the fault The signal is an analog signal obtained by the machine when a fault occurs and pre-stored in the corresponding fault signal library.

[0060] The step S101 is to obtain the signals of the machine in the three states, as the signal basis for subsequent generation of the corresponding atlas, so as to facilitate the comparison of the on-site signals with the normal signals and fault signals, so as to realize the early warning of machine faults.

[0061] In this embodiment, the fault signal library stores all known faults that may occur in the machine equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com