Drying device for raw materials of slow-release magnetized compound fertilizer

A drying device and compound fertilizer technology, applied in drying, drying machine, manure drying, etc., can solve the problems of poor drying effect, inability to effectively dry the bottom fertilizer, low efficiency, etc., and achieve the goal of ensuring the drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

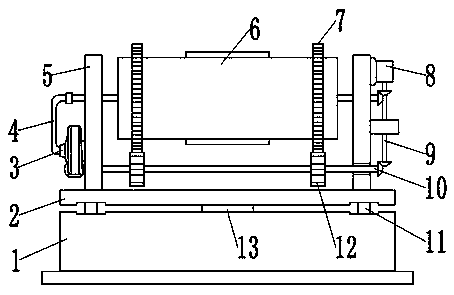

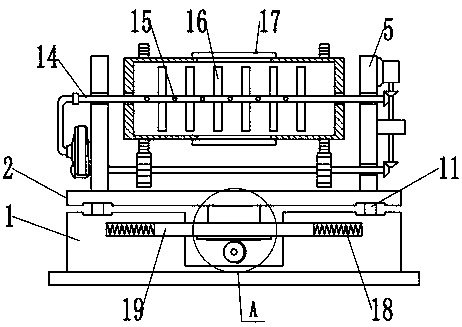

[0025] see figure 1 with 3 , in an embodiment of the present invention, a slow-release magnetized compound fertilizer raw material drying device includes a base 1, a platform 2 and a drying cylinder 6; two racks 5 are symmetrically fixed on the left and right sides of the platform 2, The drying cylinder 6 is arranged between the root racks 5, and the upper and lower sides of the drying cylinder 6 are symmetrically provided with two feeding ports 17, which are used for adding and discharging the fertilizer to be dried; the drying cylinder 6 The internal rotation of the shaft 14 is installed, and the two ends of the stirring shaft 14 extend out of the drying cylinder 6 and are connected to the frame 5 in rotation. The stirring shaft 14 is a hollow structure, and the stirring shaft 14 is located on the shaft section inside the drying cylinder 6. Several air holes 15 are uniformly provided, and a hot air blower 3 is also fixedly installed on the outside of the frame 5, and the ex...

Embodiment 2

[0032] see figure 1 with 3 , in an embodiment of the present invention, a slow-release magnetized compound fertilizer raw material drying device includes a base 1, a platform 2 and a drying cylinder 6; two racks 5 are symmetrically fixed on the left and right sides of the platform 2, The drying cylinder 6 is arranged between the root racks 5, and the upper and lower sides of the drying cylinder 6 are symmetrically provided with two feeding ports 17, which are used for adding and discharging the fertilizer to be dried; the drying cylinder 6 The internal rotation of the shaft 14 is installed, and the two ends of the stirring shaft 14 extend out of the drying cylinder 6 and are connected to the frame 5 in rotation. The stirring shaft 14 is a hollow structure, and the stirring shaft 14 is located on the shaft section inside the drying cylinder 6. Several air holes 15 are uniformly provided, and a hot air blower 3 is also fixedly installed on the outside of the frame 5, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com