Natural gas filtration and dehydration equipment

A technology for filtration and dehydration and natural gas, which is applied in the fields of gas fuel, petroleum industry, fuel, etc., can solve the problems of low efficiency, numerous equipment and high cost, and achieve the effect of convenient viewing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

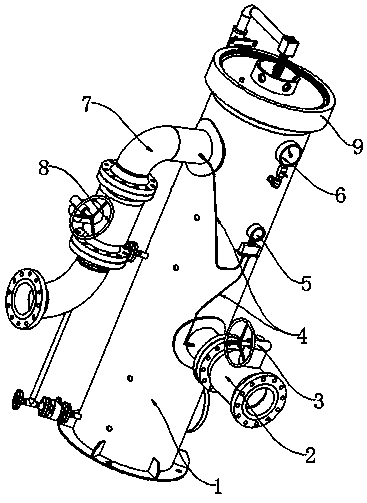

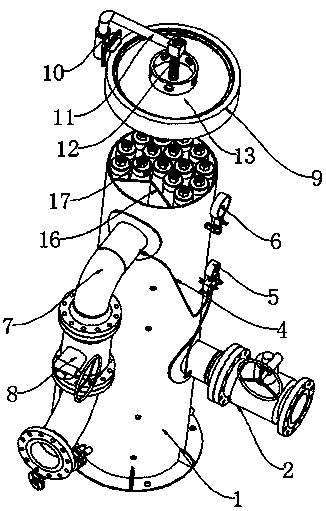

[0052] see Figure 1-7 , a kind of natural gas filter dehydration equipment of the present invention, comprises:

[0053] Tank body 1, the tank body 1 is a long cylindrical structure;

[0054] Demister 21, said demister 21 is arranged on the bottom of said tank body 1, wherein,

[0055] The top of the demister 21 is connected with the lower support plate 20;

[0056] Folded plate 16, the folded plate 16 is arranged on the top of the demister 21, wherein, the top of the folded plate 16 is welded to the upper support plate 19, wherein,

[0057] A cavity 18 is formed between the flap 16 and the tank body 1;

[0058] Cyclone separator 17, the cyclone separator 17 is arranged on the top of the upper support plate 19;

[0059] An air intake duct 7, one end of the air intake duct 7 communicates with the cavity 18 inside the tank body 1;

[0060] An exhaust pipe 2, one end of the exhaust pipe 2 communicates with the bottom of the tank body 1;

[0061] A cover assembly, the cover a...

Embodiment 2

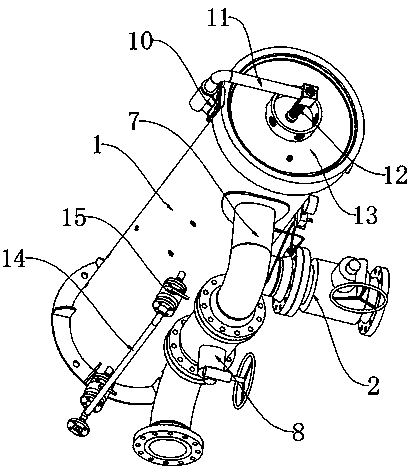

[0064] see Figure 1-7 , the present invention is a kind of natural gas filtration and dehydration equipment, and the cover assembly includes:

[0065] A cover 9, the cover 9 is set on the top of the tank 1;

[0066] A fixing base 10, the fixing base 10 is fixed on one side of the cover 9;

[0067] A rotating shaft 11, one end of the rotating shaft 11 is inserted into the inside of the fixed seat 10, so that the rotating shaft 11 can rotate inside the fixed seat 10;

[0068] Screw mandrel 12, one end of described screw mandrel 12 is fixed with the other end of described rotating shaft 11;

[0069] A sealing cover 13, the sealing cover 13 is arranged inside the cover body 9, wherein,

[0070] The outer edge of the sealing cover 13 is threadedly connected with the inner edge of the cover body 9 , so as to realize the threaded connection between the middle part of the sealing cover 13 and the screw rod 12 .

[0071] When the sealing cover 13 needs to be opened, the sealing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com