A kind of preparation method of emulsion type cumyl peroxyneodecanoate

A technology of cumyl decanoate and cumene hydroperoxide, which is applied in the field of preparation of emulsion-type cumyl peroxyneodecanoate, can solve problems such as content reduction, decreased triggering activity, and increased unit consumption. To achieve the effect of enhancing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

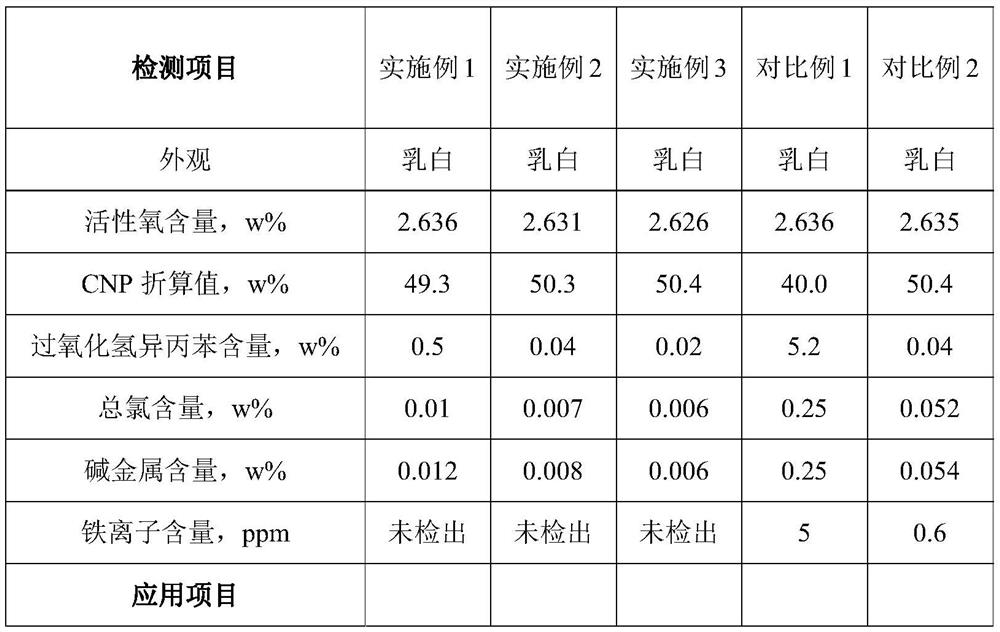

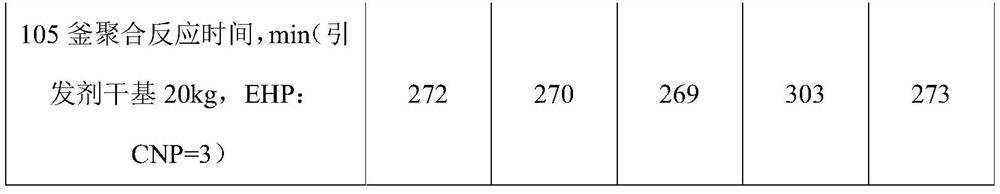

Examples

Embodiment 1

[0070] A kind of preparation method of emulsion type cumyl peroxyneodecanoate comprises the steps:

[0071] synthesis:

[0072] (1) 600kg of cumene hydroperoxide is added dropwise in 25% potassium hydroxide lye, the dry basis mass ratio of said lye and cumene hydroperoxide is 0.4:1, the time for adding is 20min, dropwise Stir for 15 minutes after the addition to obtain solution 1;

[0073] (2) Add neodecanoyl chloride dropwise to solution 1, the dry basis mass ratio of cumene hydroperoxide to neodecanoyl chloride is 0.8:1, the dropwise addition time is 45min, after the dropwise addition is completed, react at 25°C for 60min , let it stand for 30 minutes, and divide the water to obtain a water-in-oil emulsion;

[0074] Purification:

[0075] (1) Wash the water-in-oil emulsion 1 time with 5% sodium hydroxide solution, the mass ratio of the dry basis of the sodium hydroxide to the water-in-oil emulsion is 0.06:1, leave it standing after washing, divide water, Obtain solution ...

Embodiment 2

[0082] A kind of preparation method of emulsion type cumyl peroxyneodecanoate comprises the steps:

[0083] synthesis:

[0084] (1) 600kg of cumene hydroperoxide is added dropwise in 35% sodium hydroxide lye, the dry basis mass ratio of said lye and cumene hydroperoxide is 0.6:1, the time for adding is 30min, dropwise Stir for 20 minutes after the addition to obtain solution 1;

[0085] (2) Add neodecanoyl chloride dropwise to solution 1, the dry basis mass ratio of cumene hydroperoxide to neodecanoyl chloride is 1.0:1, the dropping time is 60min, after the dropping is completed, react at 35°C for 90min , let it stand for 45 minutes, and divide the water to obtain a water-in-oil emulsion;

[0086] Purification:

[0087] (1) Wash the water-in-oil emulsion 2 times with 25% sodium sulfite solution, the mass ratio of the dry basis of the sodium sulfite to the water-in-oil emulsion is 0.1:1, leave it to stand after each washing, and divide the water to obtain the solution 2;

...

Embodiment 3

[0094] A kind of preparation method of emulsion type cumyl peroxyneodecanoate comprises the steps:

[0095] synthesis:

[0096] (1) 600kg cumene hydroperoxide is added dropwise in 30% potassium hydroxide lye, the dry basis mass ratio of said lye and cumene hydroperoxide is 0.5:1, and the time for adding is 25min, dropwise Stir for 30 minutes after the addition to obtain solution 1;

[0097] (2) Add neodecanoyl chloride dropwise to solution 1, the mass ratio of cumene hydroperoxide to neodecanoyl chloride on a dry basis is 0.9:1, and the dropping time is 50 minutes. After the dropping is completed, react at 30°C for 75 minutes , let it stand for 36 minutes, and divide the water to obtain a water-in-oil emulsion;

[0098] Purification:

[0099] (1) Wash the water-in-oil emulsion 2 times with 15% sodium bisulfite solution, the dry basis of the sodium bisulfite and the mass ratio of the water-in-oil emulsion are 0.08:1, leave standstill after each washing , divided into water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com