Material conveying device

A technology for conveying devices and materials, which is applied in the direction of packaging, etc., can solve the problems of affecting the conveying tempo, low arrangement efficiency, and cost, and achieve the effect of stable arrangement effect, high arrangement efficiency and consistent orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] see figure 1 , a material conveying device, including a housing 1, a feed inlet 2 is opened above the housing 1, and a straightening assembly is arranged below the feeding inlet 2, and the straightening assembly includes a driving roller 3 and a driven roller The roller 4, the driving roller 3 and the driven roller 4 are in the same horizontal plane and are in rolling contact with each other, the cylindrical surface of the driving roller 3 is partially cut off to form a plane 5; a conveyor belt 6 for conveying materials is provided below the centering assembly, The conveying end of the conveyor belt 6 is provided with a turning mechanism;

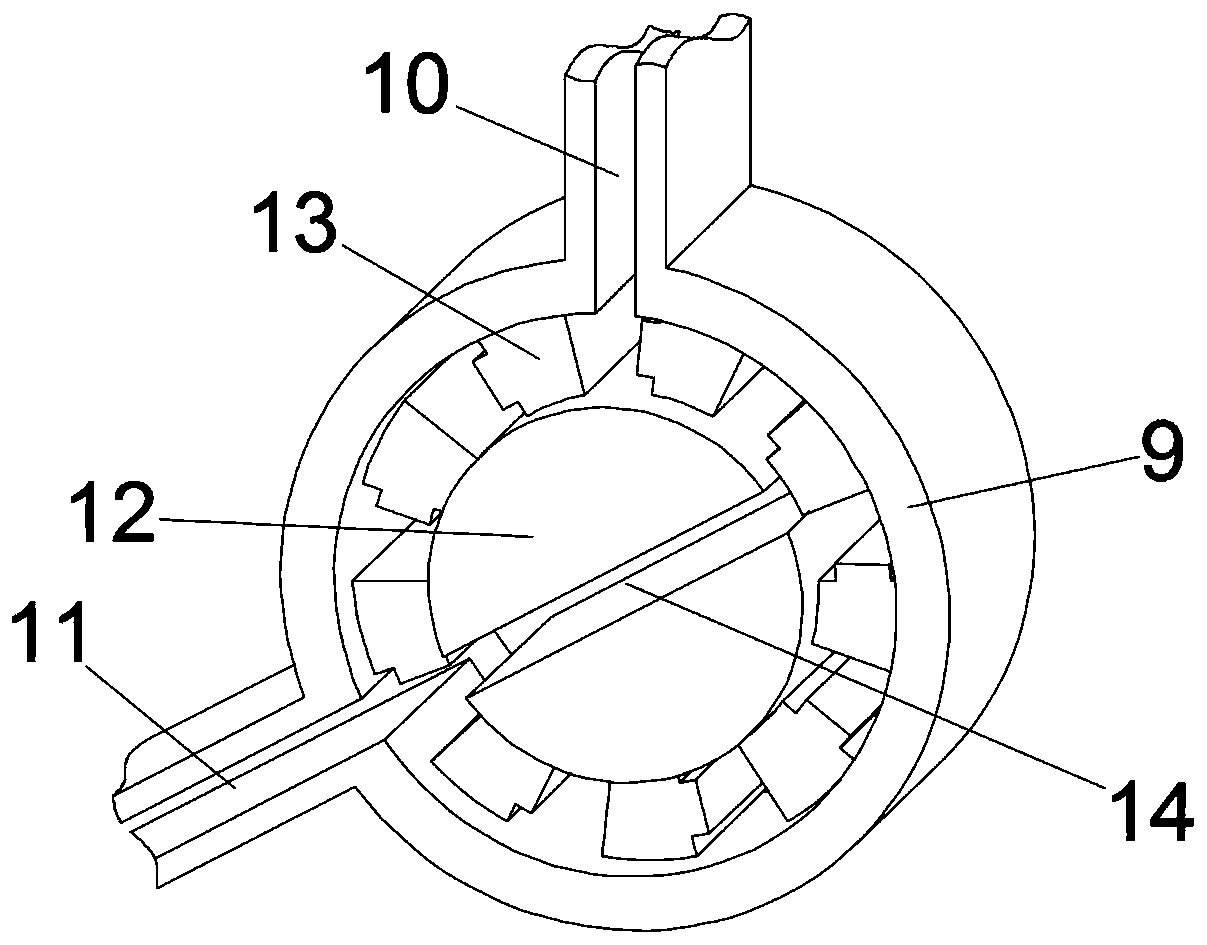

[0022] see figure 2 , the turning mechanism includes a ring 9, a half cylinder 12 and a holding block 13, two half cylinders 12 are fixed inside the ring 9, and an inclined downward chute is formed between the two half cylinders 12 14. A circular channel is formed between the outer cylindrical surface of the semi-cylinder 12 and t...

Embodiment 2

[0033] In order to facilitate the same packaging of the channel steel discharged from the discharge channel 11, this embodiment has been further improved on the basis of embodiment 1. The improvement is: there are several rows and The outlet of the discharge channel 11 is connected to the roller 16 that can roll freely. The bottom of the roller 16 is provided with a mounting seat 17, and the mounting seat 17 is fixed on the shell 1 through the fixing frame 15; After the steel is discharged from the discharge channel 11, it slides onto the drum 16 in sequence, and the operator can pack the channel steel.

[0034] The material conveying device is equipped with a straightening component and a turning mechanism to carry out uniform arrangement while conveying messy and disordered channel steel to ensure that the channel steel at the output end is placed neatly and at the same time in the same direction. Compared with traditional manual arrangement, it greatly saves manpower. , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com