Splicing and pressure-maintaining device for wooden furniture

A pressure-maintaining device and a technology for wooden furniture, which are applied in the joining of wooden veneers, manufacturing tools, and wood processing appliances, etc., can solve the problems of uneven force, skewed joints, inconvenience, etc., and achieve the loading and pressure-maintaining operation. The process is labor-saving and the pressure is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

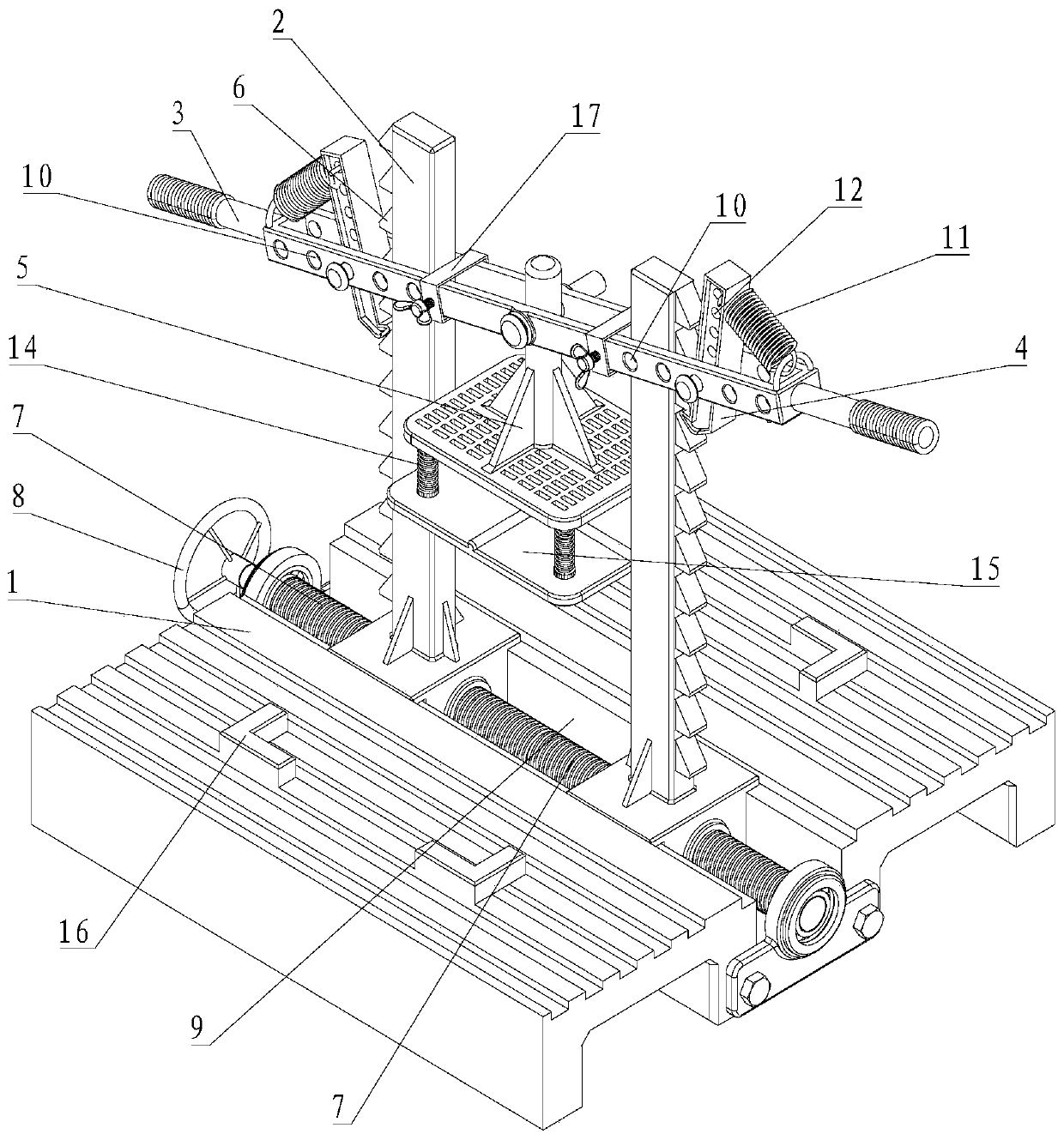

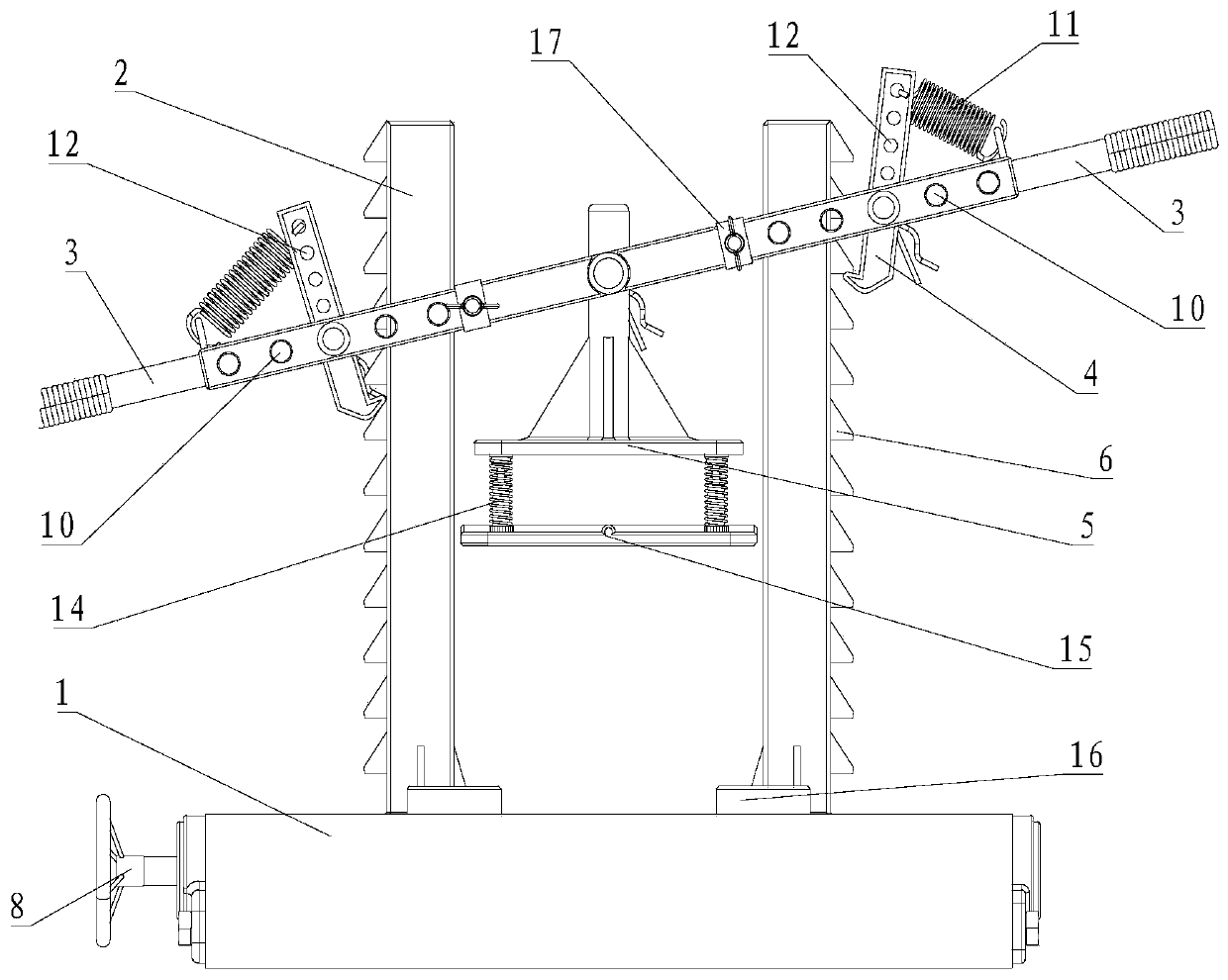

[0078] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is:

[0079] A splicing and pressure maintaining device for wooden furniture, comprising a tooling table 1, a lifting frame 2, a rocker 3, a claw hook 4 and a loading table 5;

[0080] The lifting frame 2 includes two;

[0081] The two lifting frames 2 are relatively arranged on the tooling table 1;

[0082] The lifting frame 2 is perpendicular to the working surface of the tooling table 1;

[0083] A plurality of successively arranged lifting teeth 6 are respectively arranged on the sides opposite to each other on the two lifting frames 2 along the vertical direction;

[0084] The upper surface of the lifting tooth 6 is a wedge surface; the lower surface of the lifting tooth 6 is a plane parallel to the horizontal direction;

[0085] The rocker 3 is sleeved on the two lifting frames 2 so as to move up and down;

[0086] The claw hook 4 includes two;

[0087] One end of the claw hook 4 i...

Embodiment 2

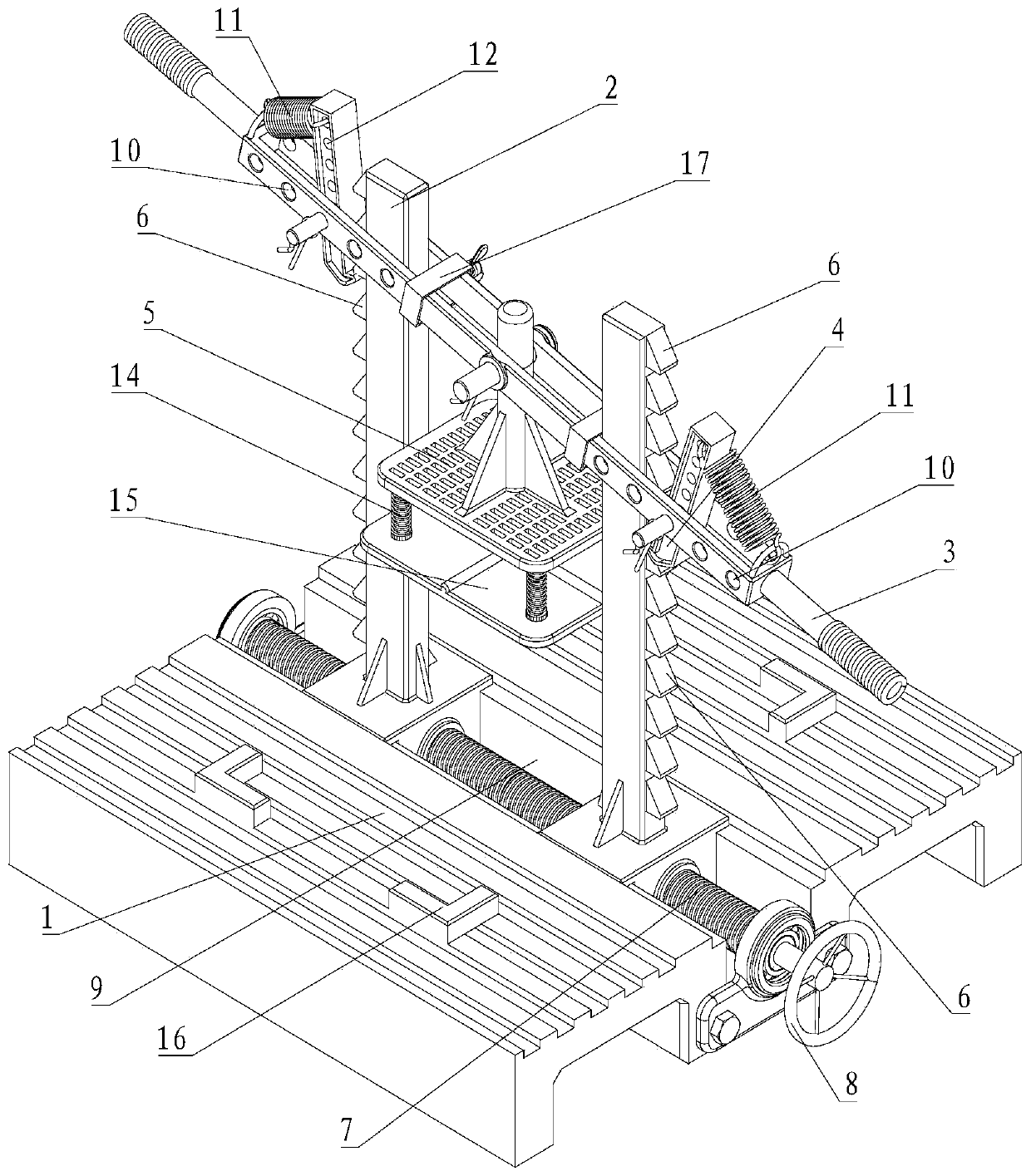

[0107] Please refer to Figure 5 to Figure 8 , the second embodiment of the present invention is:

[0108] A splicing and pressure maintaining device for wooden furniture, comprising a tooling table 1, a lifting frame 2, a rocker 3, a claw hook 4 and a loading table 5;

[0109] The lifting frame 2 includes two;

[0110] The two lifting frames 2 are relatively arranged on the tooling table 1;

[0111] The lifting frame 2 is perpendicular to the working surface of the tooling table 1;

[0112] On the opposite sides of the two lifting frames 2, a plurality of lifting teeth 6 arranged in sequence are respectively arranged along the vertical direction;

[0113] The upper surface of the lifting tooth 6 is a wedge surface; the lower surface of the lifting tooth 6 is a plane parallel to the horizontal direction;

[0114] The rocker 3 is sleeved on the two lifting frames 2 so as to move up and down;

[0115] The claw hook 4 includes two;

[0116] Each lifting frame 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com