Ointment for treating burns and scalds and production method of ointment for treating burns and scalds

A technology for burns and scalds and ointment, which is applied in the field of ointment for treating burns and scalds and its preparation field, can solve the problems of increasing the mental burden of patients in the treatment process, economic burden, slow healing, long healing time, etc., and achieves reduction of wound surface liquid exudation and regeneration speed. Faster and less painful for the patient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

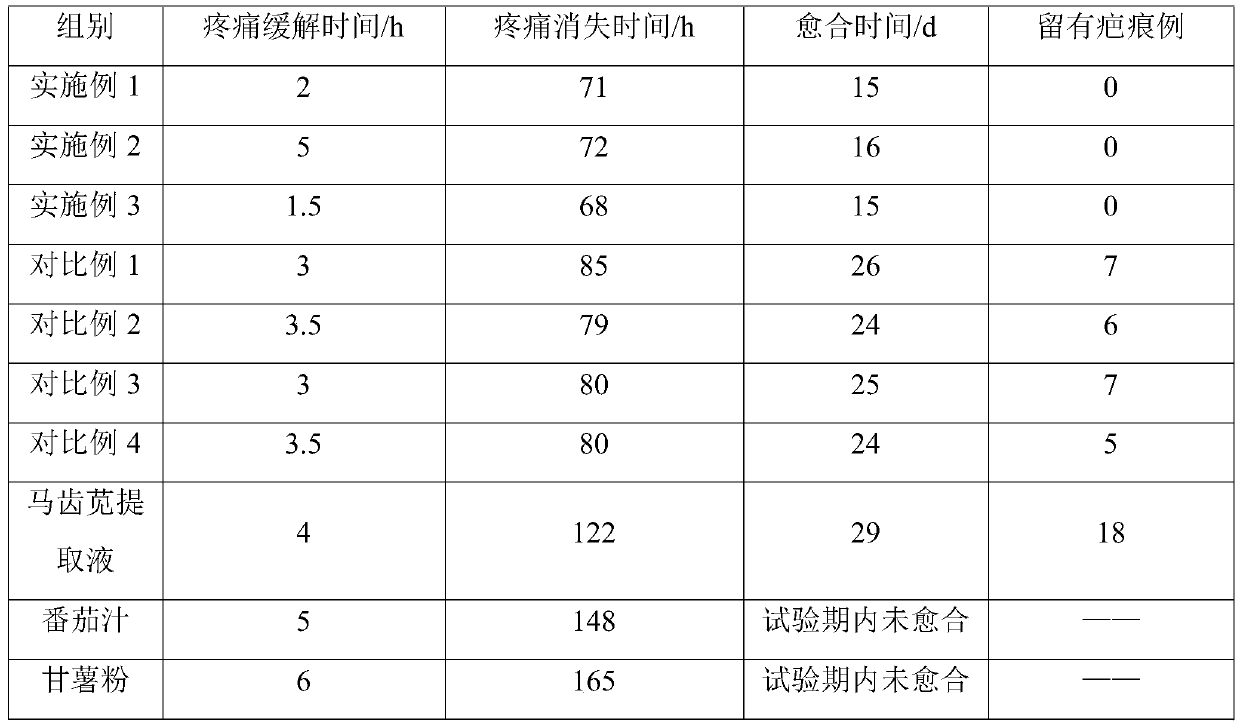

Examples

Embodiment 1

[0018] An ointment for treating burns and scalds, which is made of the following raw materials in parts by weight: 2 parts of angelica, 3 parts of Burnet, 2 parts of Qingdai, 8 parts of beeswax, 2 parts of purslane extract, 1 part of tomato, 2 parts of sweet potato 6 parts, 6 parts of comfrey, 6 parts of pine oil, 35 parts of arborvitae, 140 parts of sesame oil.

[0019] The preparation method of the ointment for the above-mentioned treatment of burns and scalds is as follows:

[0020] (1) Mince the purslane and put it into the reflux extraction device, add 5 times the amount of clear water and heat to boil, collect the distillate, filter, and collect the filtrate for later use; continue to add 3 times the amount of clear water to the broken residue and continue to heat and reflux for extraction for 2 hours. Take the filtrate by filtration and set aside; combine the two filtrates and concentrate under reduced pressure until the relative density is 1.2 to 1.3 at 80°C to obtain ...

Embodiment 2

[0026] An ointment for treating burns and scalds, which is made of the following raw materials in parts by weight: 5 parts of angelica, 6 parts of Burnet, 5 parts of Qingdai, 12 parts of beeswax, 4 parts of purslane extract, 2 parts of tomato, 5 parts of sweet potato 8 parts, 8 parts of comfrey, 8 parts of pine oil, 40 parts of arborvitae, 160 parts of sesame oil.

[0027] The preparation method of the ointment for the above-mentioned treatment of burns and scalds is as follows:

[0028] (1) Mince the purslane and put it into the reflux extraction device, add 5 times the amount of clear water and heat to boil, collect the distillate, filter, and collect the filtrate for later use; continue to add 3 times the amount of clear water to the broken residue and continue to heat and reflux for extraction for 2 hours. Take the filtrate by filtration and set aside; combine the two filtrates and concentrate under reduced pressure until the relative density is 1.2 to 1.3 at 80°C to obtai...

Embodiment 3

[0034] An ointment for treating burns and scalds, which is made of the following raw materials in parts by weight: 3 parts of angelica, 5 parts of Burnet, 4 parts of Qingdai, 10 parts of beeswax, 3 parts of purslane extract, 1.5 parts of tomato, 4 parts of sweet potato 7 parts, 7 parts of comfrey, 7 parts of pine oil, 38 parts of arborvitae, 150 parts of sesame oil.

[0035] The preparation method of the ointment for the above-mentioned treatment of burns and scalds is as follows:

[0036] (1) Mince the purslane and put it into the reflux extraction device, add 5 times the amount of clear water and heat to boil, collect the distillate, filter, and collect the filtrate for later use; continue to add 3 times the amount of clear water to the broken residue and continue to heat and reflux for extraction for 2 hours. Take the filtrate by filtration and set aside; combine the two filtrates and concentrate under reduced pressure until the relative density is 1.2 to 1.3 at 80°C to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com