pneumatic tire

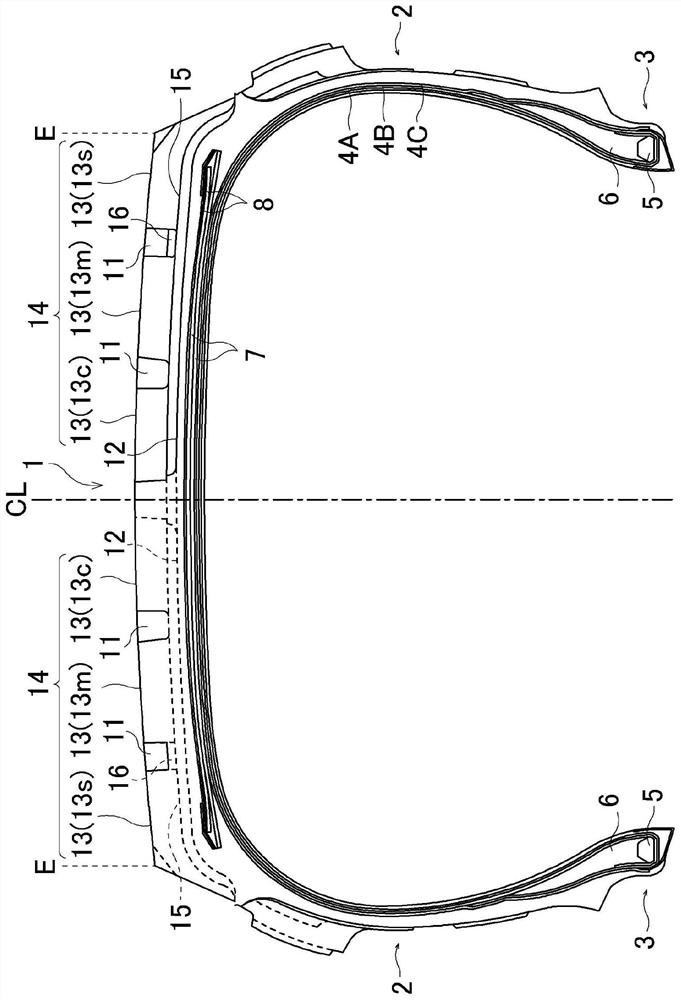

A technology for pneumatic tires and tires, which is applied to off-road vehicle tires, tire parts, tire treads/tread patterns, etc., which can solve problems such as difficulty in ensuring wear resistance and decreased rigidity, and achieve improved driving performance and traction sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

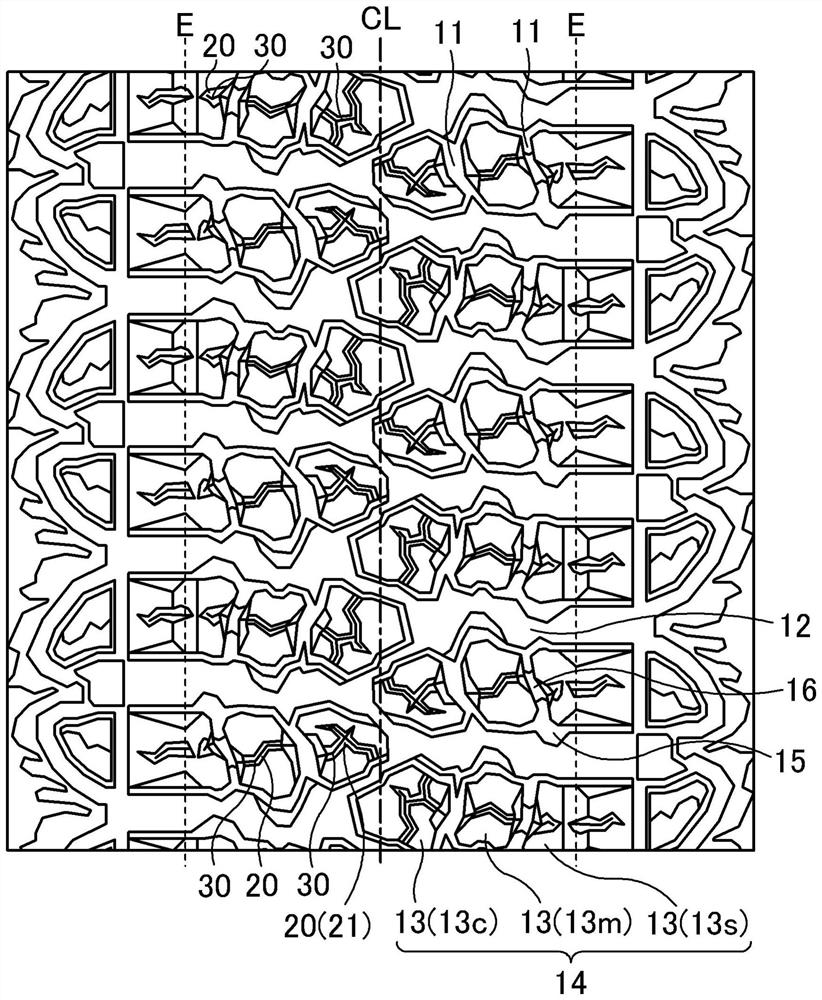

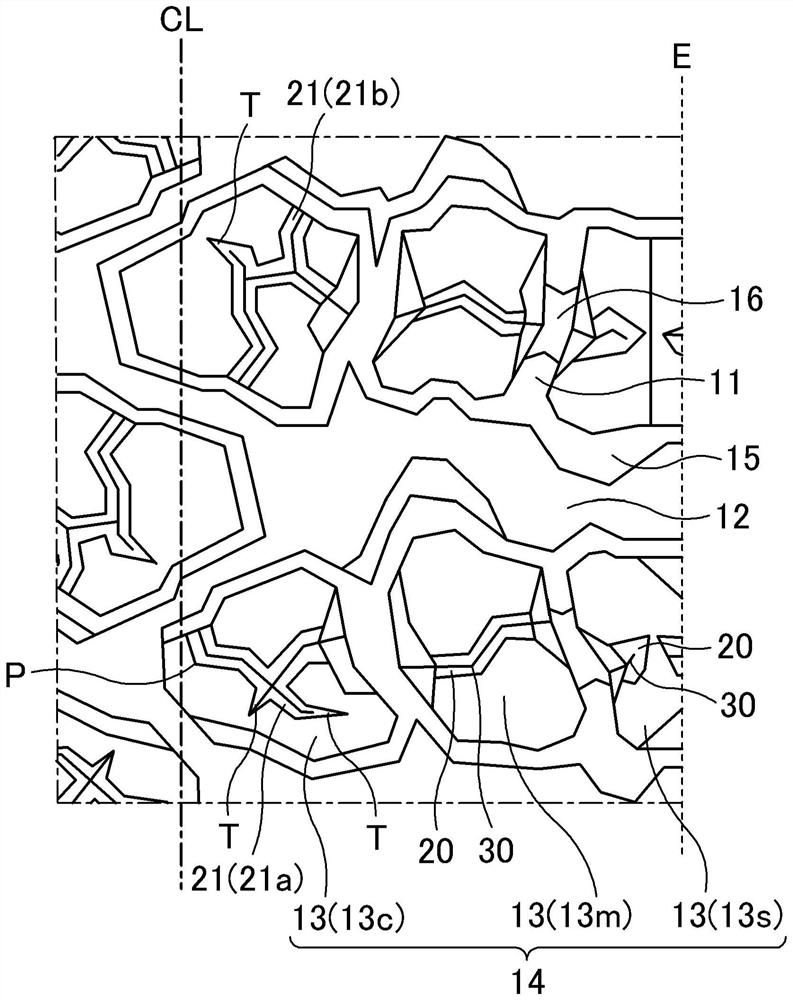

[0038] Made a tire size 35×12.50R17 with figure 1 The basic structure of the example and the figure 2 The tread pattern is the keynote and the presence or absence of shallow grooves, the depth of shallow grooves, the number of inflection points of shallow grooves provided at each block, the presence or absence of sipe patterns at the bottom of shallow grooves, and the presence or absence of shallow grooves in the center The presence or absence of the end portion of the groove and the number of the end portion of the central shallow groove were set as shown in Table 1 for 12 pneumatic tires of Comparative Examples 1 to 4 and Examples 1 to 8, respectively.

[0039] In addition, Comparative Example 1 is an example without shallow grooves and sipes, and is obtained from figure 2 The shape of the tread pattern after removing the shallow grooves and sipes in each part. Comparative example 2 is based on figure 2 The tread pattern is the keynote and the outline of the shallow gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com