Intercooler and oil-free piston compressor comprising same

A compressor and oil piston technology, applied in the field of compressors, can solve problems such as limiting the maximum discharge pressure of the compressor, and achieve the effects of improving cooling effect, improving heat dissipation efficiency and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

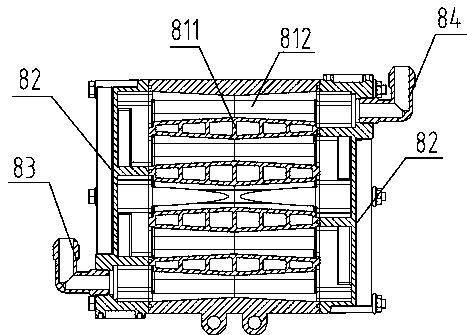

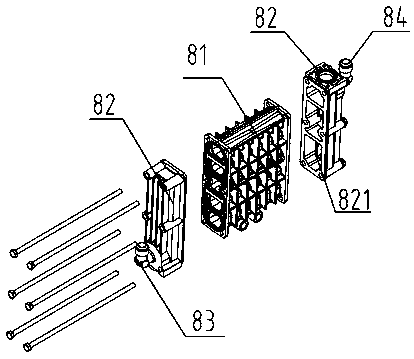

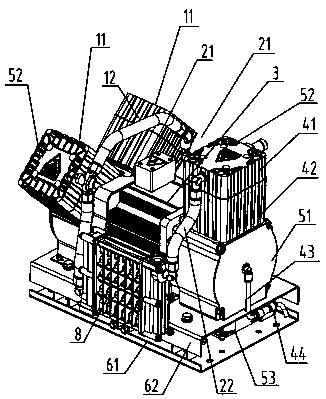

[0028] Such as figure 1 and figure 2 As shown, an intercooler includes a radiator 81, and the radiator 81 includes a number of heat dissipation pipes arranged side by side, and a heat dissipation space is formed between two adjacent heat dissipation pipes, and heat dissipation fins are arranged in the heat dissipation space. 811. Each of the heat dissipation pipes is provided with a heat dissipation channel 812 axially penetrating through the heat dissipation pipes. The heat dissipation channel 812 gradually shrinks from both ends to the middle. It also includes a cap 82 arranged at both ends of the radiator 81 and detachably connected to the radiator 81 , and an air distribution channel 821 is provided in the cap 82 . Several heat dissipation passages 812 are sequentially connected end to end through the air distribution passage 821 . A cooling air inlet 83 and a cooling air outlet 84 are also included.

[0029] The form of end-to-end connection is adopted to increase t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com