Heating film and preparation method thereof, device adopting heating film and preparation method for device

A heating film, thermal insulation technology, used in electric heating devices, heating element materials, ohmic resistance heating and other directions, can solve the problems of unenvironmental protection, short service life, fast aging and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] The present invention is further described below by way of examples, but the present invention is not limited to the scope of the described examples.

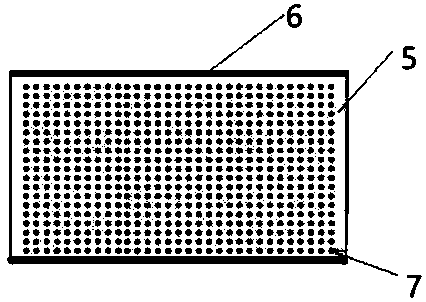

[0123] A heating film 12 of the present invention includes several layers of graphene and carbon fibers, wherein the weight proportion of the graphene is 0.1-5 parts, and the weight proportion of the carbon fibers is 60-80 parts. The graphene is a graphene film, and several layers of graphene films are used to increase electrical conductivity and efficiency. Carbon fiber has good electrical conductivity, and the resistivity is different with different content of chopped carbon fiber in carbon fiber. In addition, carbon fiber has the characteristics of light, thin and soft, good mechanical properties, excellent thermal conductivity, and excellent electrical and thermal properties. The heating film 12 also includes bamboo pulp, a dispersant, a coupling agent and a defoaming agent. The weight proportion of the coupling ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com