Passenger vehicle ultimate strength impact test platform auxiliary device

A technology of ultimate strength and impact test, applied in the direction of vehicle impact test, measurement device, vehicle test, etc., can solve the problems of high cost, unsuitable for frequent replacement of tooling, long time consumption, etc., and achieves high work efficiency, convenient operation and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

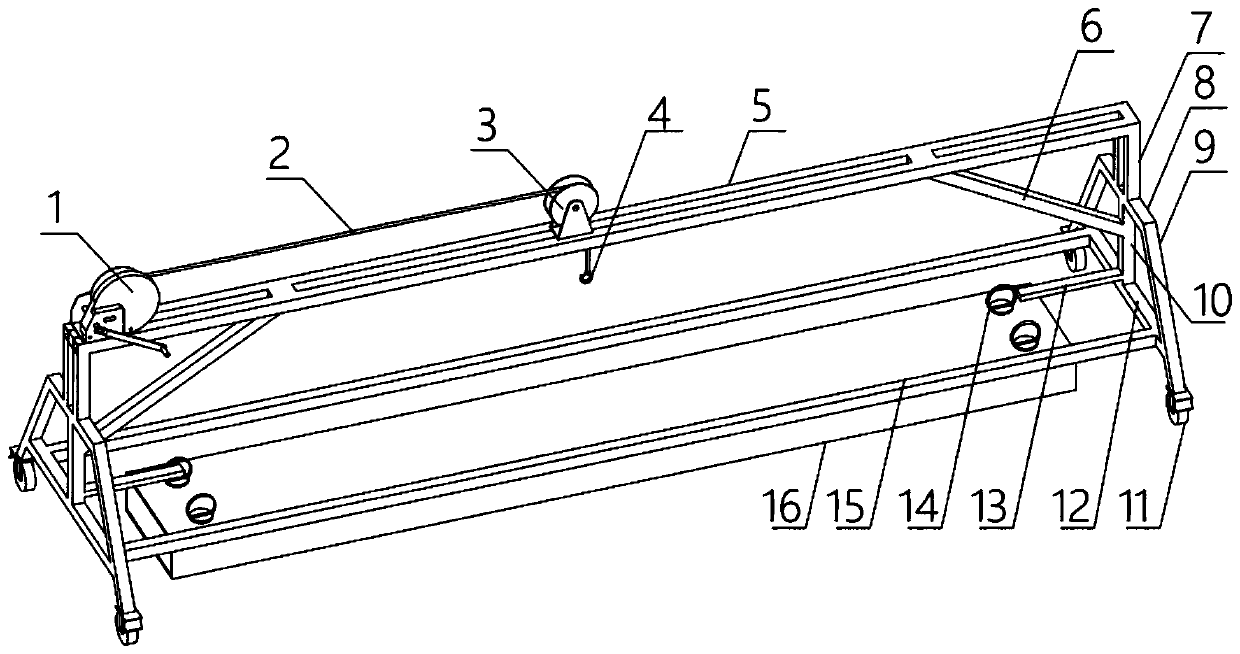

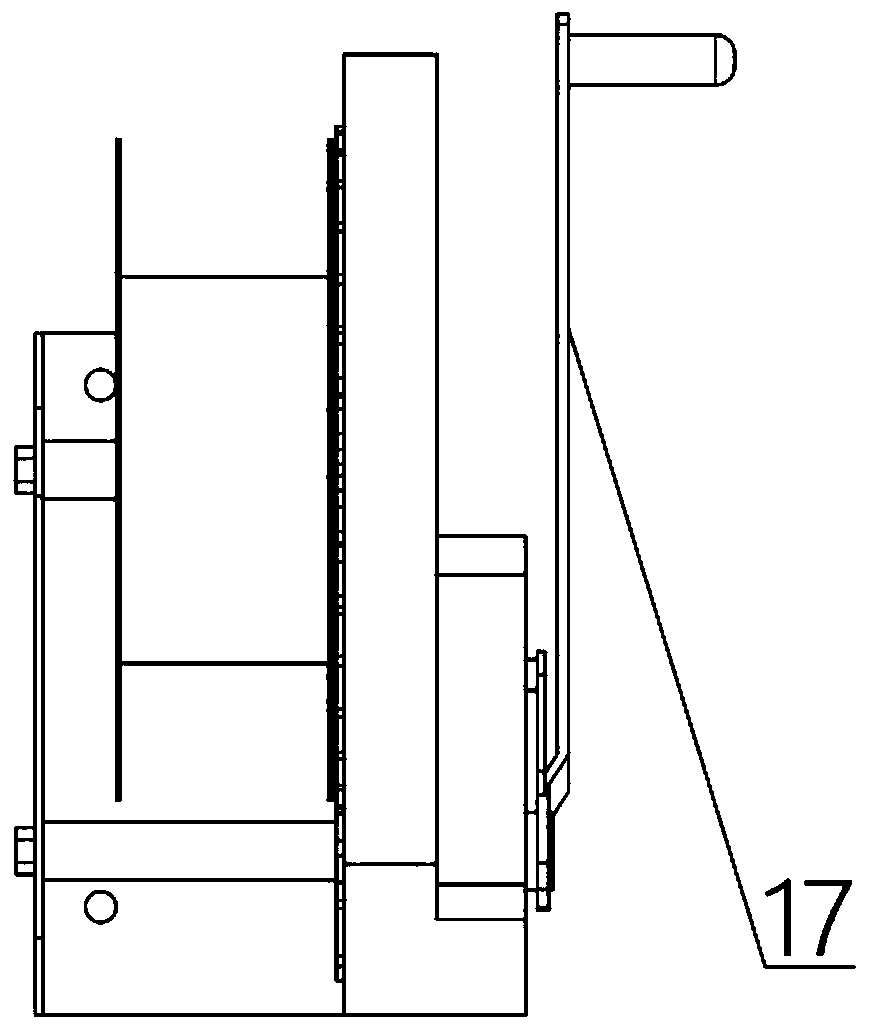

[0019] to combine Figure 1 to Figure 2 The diagram of an auxiliary device for a passenger car ultimate strength impact test platform shown in this embodiment includes two sets of frame bodies arranged in parallel, a beam 5 connected between the two sets of frame bodies, and two sets of lateral Limiting plate 15, the self-locking hand winch 1 that is fixedly installed on one end of crossbeam 5 and the guide wheel 3 that is fixedly installed in the middle part of crossbeam 5, the universal wheel 11 that present embodiment adopts is universal brake caster, and self-locking hand winch The winch 1 has a lifting wire rope 2, and the lifting wire rope 2 bypasses the guide wheel 3 and hangs vertically below the beam 5. The bottom end of the lifting wire rope 2 is also connected with a closed hook 4; the frame body includes an upper column 7 and an upper longitudinal beam 8 , two groups of longitudinal support 9, lower column 10 and lower longitudinal beam 12, the top of upper column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com