Yarn collecting plate type broken yarn detection device of warping machine

A technology for yarn breakage detection and yarn collecting board, which is applied to other manufacturing equipment/tools, textiles and papermaking, manufacturing tools, etc., can solve the problems of long output time of breakage signal, non-stop yarn breakage, affecting warping quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

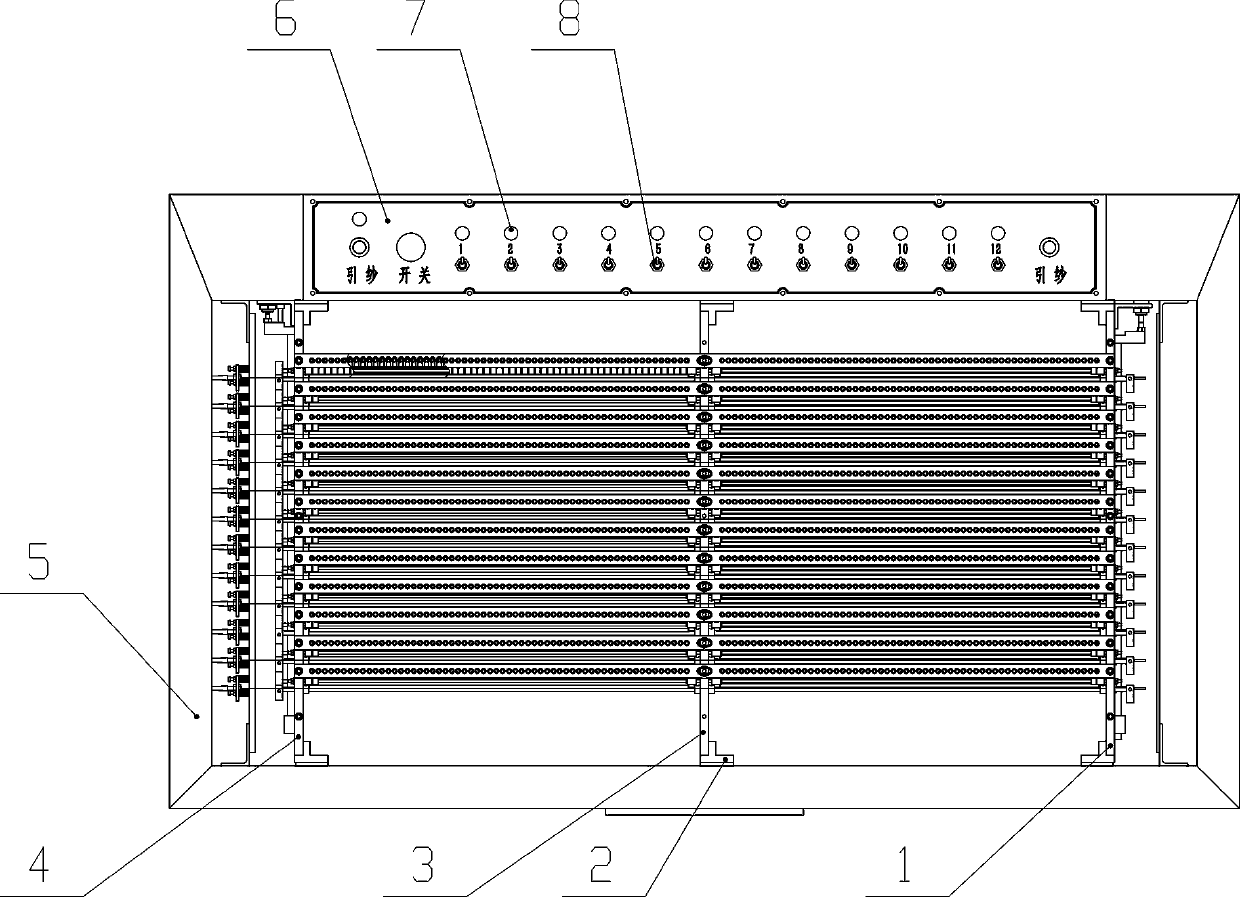

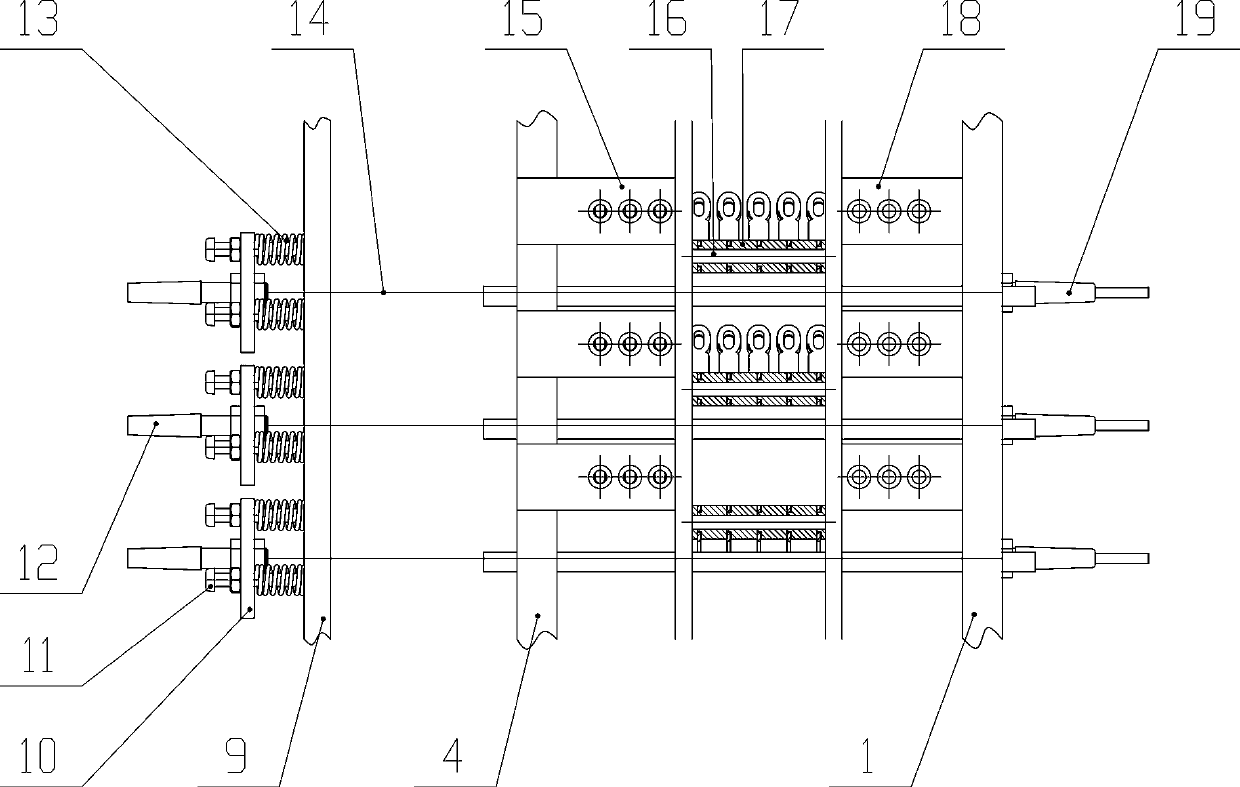

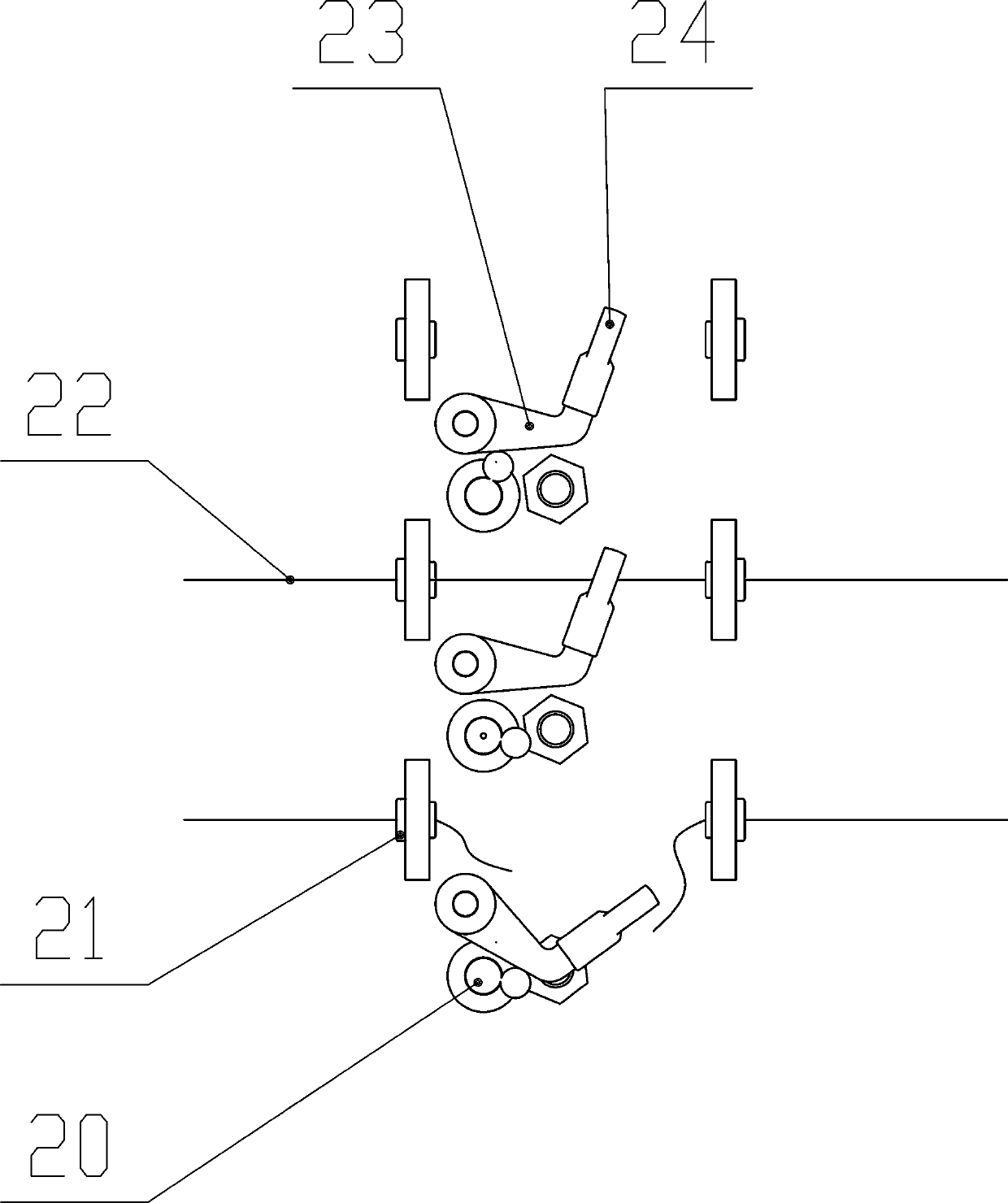

[0015] Depend on figure 1 , figure 2 and image 3 It can be seen that the warping machine yarn breakage detection device of the present invention is a warping machine filament collecting plate type yarn breakage detection device, which is characterized in that: the left vertical board 4, the middle vertical board 3 and the right vertical board are fixed in the frame 5 with corner seats 2 The two sides of 1, according to certain spacing up and down, are equipped with multi-layer front yarn guide plate 15 and rear yarn guide plate 18, are glued with porcelain eyes 21 on the front yarn guide plate 15 and rear yarn guide plate 18, in each layer front yarn guide plate 15 Between the back guide plate 18, there is a support bar 16, which passes through the left vertical plate 4, the neutral plate 3 and the right vertical plate 1 respectively, and many spacer sleeves 17 and yarn guide hooks 23 are arranged successively on the support bar 16. There is long porcelain eye 24 on the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com