Two-dimensional tracking robot spraying programming method

A programming method and robot technology, applied in two-dimensional position/channel control, instruments, spraying devices, etc., can solve the problems of increased robot positioning distance, high equipment investment cost, and increased spray booth space, etc., to achieve robot Reduced loss, improved work efficiency, and reduced wire speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

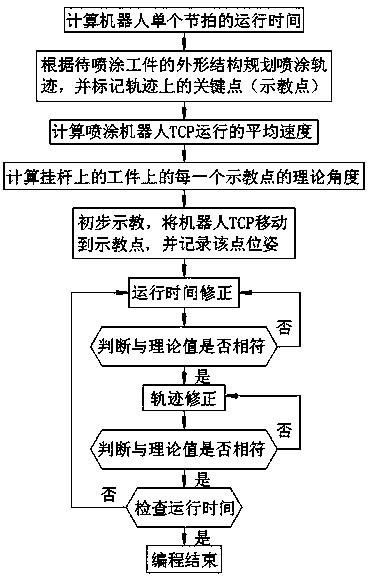

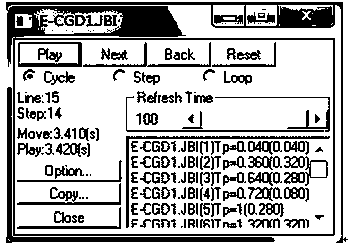

[0031] refer to figure 1 , 2 , a two-dimensional tracking robot spraying programming method, comprising the following steps:

[0032] (1) Calculate the running time of a single beat of the robot: from the time when the workpiece reaches the spraying area, the workpiece moves in parallel with the conveyor chain and rotates around the hanging rod. The production beat is obtained by dividing each pitch S of the conveyor chain by the chain speed V, The workpiece rotates with the hanger in place at a constant angular velocity for one circle (360°), the corresponding time is T, and the theoretical running time T of a single beat of the robot is calculated. 0 ;

[0033] (2) Plan the spraying trajectory according to the shape and structure of the workpiece to be sprayed, and mark the key points on the trajectory: take the key points as the teaching points, the workpiece is rotated in situ for trajectory teaching, and the instructions required for spraying are marked on the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com