Rotating disc type particulate matter sampler capable of automatically changing film

A technology of automatic membrane change and turntable type, which is applied in the direction of sampling, instruments, scientific instruments, etc., can solve the problems of multiple power sources, complex transmission mechanism, large volume, etc., and achieve the advantages of reduced volume, accurate control, and simple structure of the whole machine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

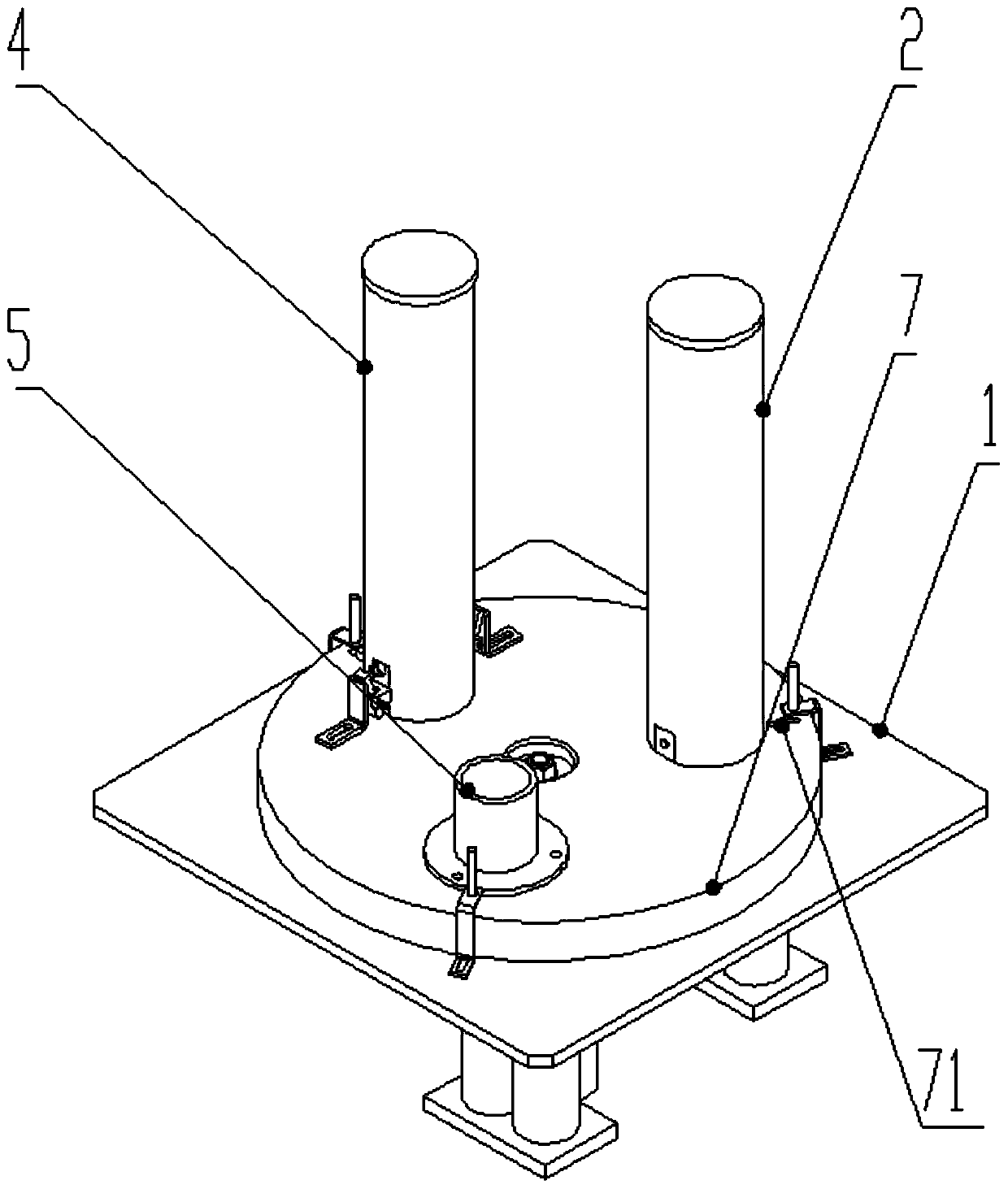

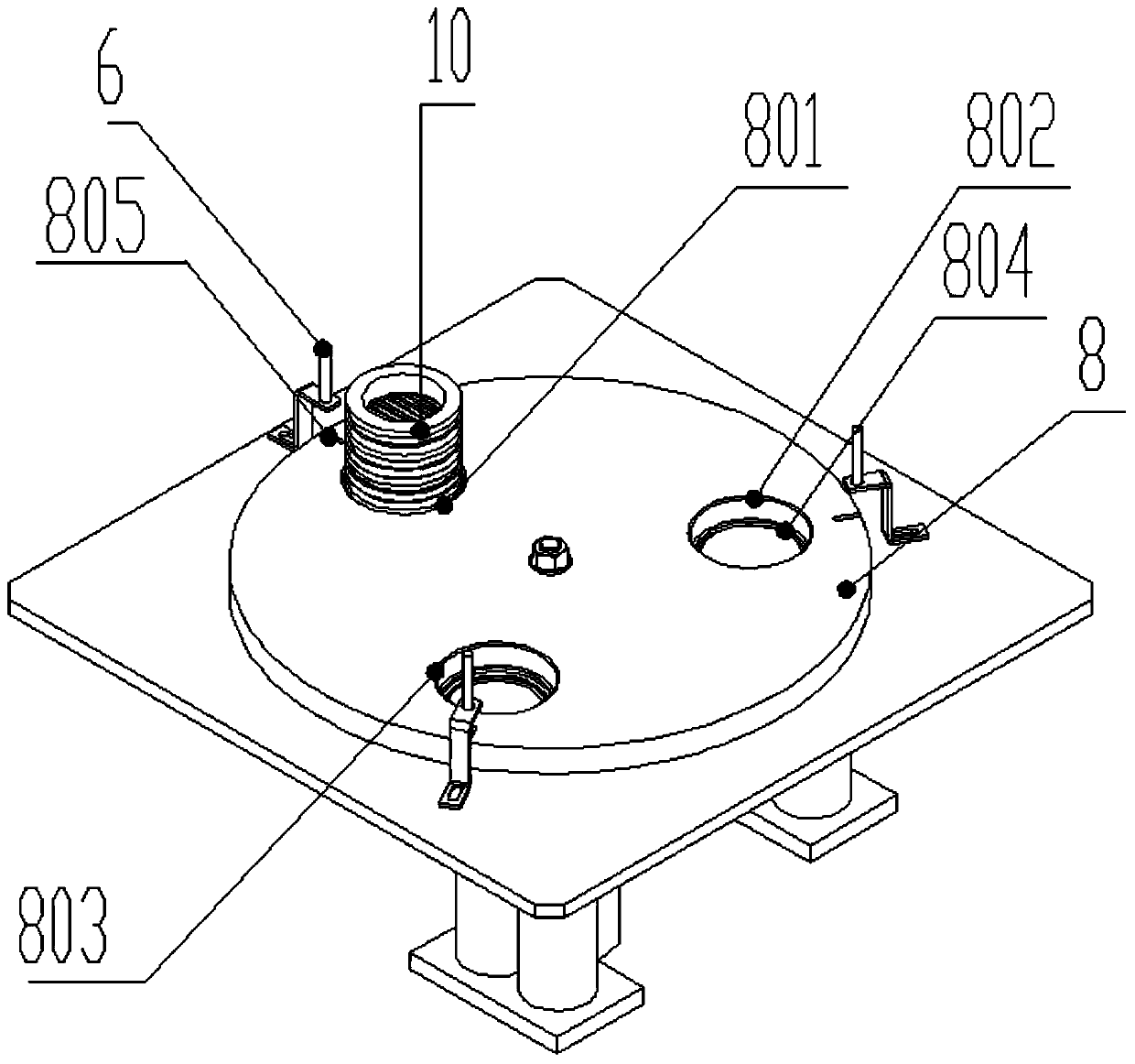

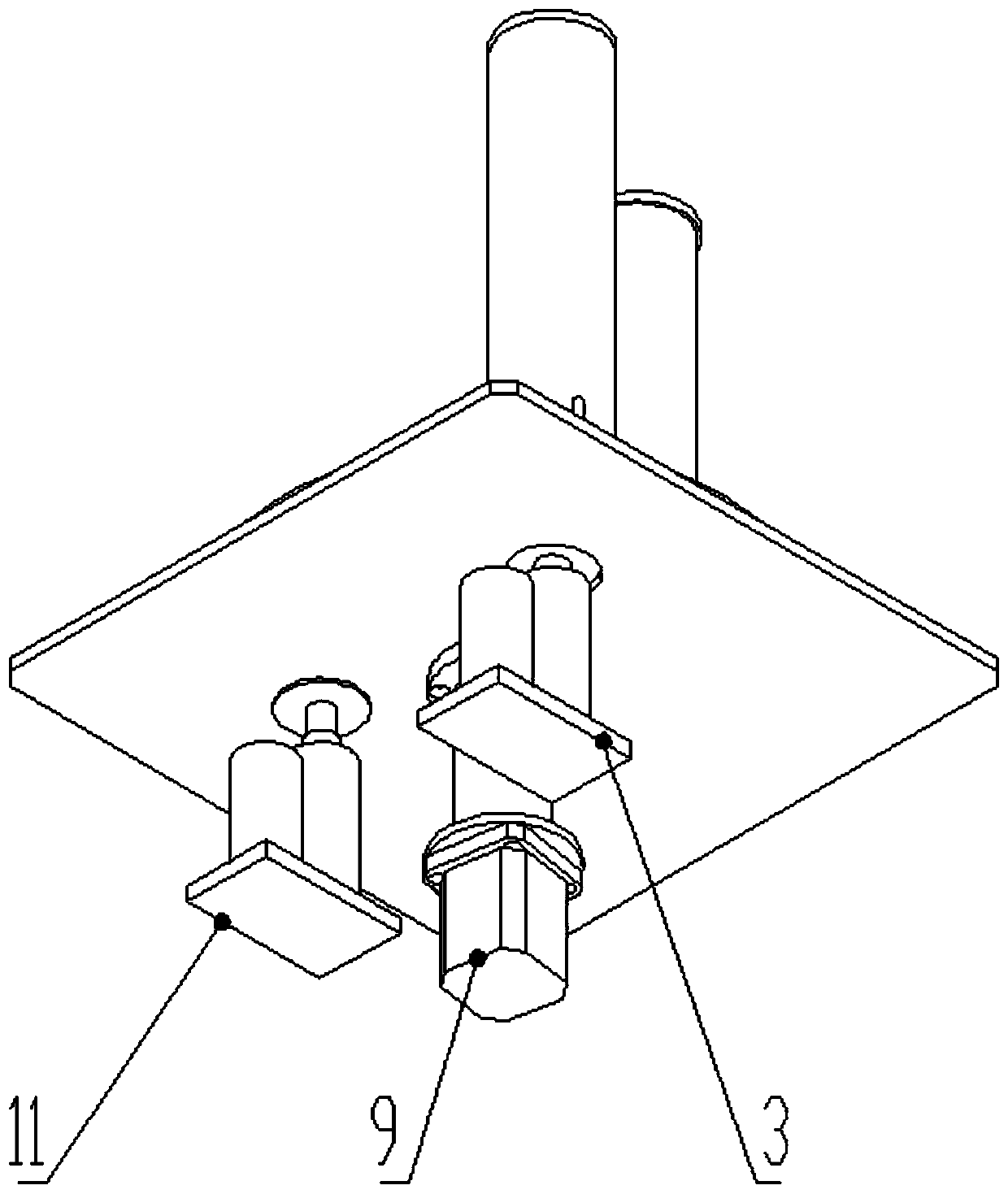

[0040] refer to figure 1 , 2 , 3. This embodiment provides a turntable particle sampler with automatic membrane change, including a base 1, a feeding and storage membrane cylinder 2, a feeding mechanism 3, a feeding and storage membrane cylinder 4, a sampling head 5, and a photoelectric switch 6 , fixed seat 7, turntable 8, turntable rotation mechanism 9, described fixed seat 7 is fixed on the base 1, and described upper material storage film cylinder 2, unloading material storage film cylinder 4, sampling head 5 are fixed on the fixed seat 7, The turntable 8 is arranged in the fixed seat 7, and is connected with the turntable rotation mechanism 9 fixed below the base 1, the feeding mechanism 3 is fixed below the base 1, and the photoelectric switch 6 is used to determine whether the turntable 8 rotates in place. Membrane holders 10 are arranged sequentially in the film storage tube 4, and fall onto the turntable 8 by gravity. The turntable rotation mechanism 9 drives the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com